Method for rapidly preparing spherical mercury sulfide nanoparticles

A technology of nano-particles and mercury sulfide, applied in chemical instruments and methods, nanotechnology, mercury compounds, etc., can solve the problems of good dispersion, energy saving and time saving, etc., and achieve good dispersion, easy access, and high stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

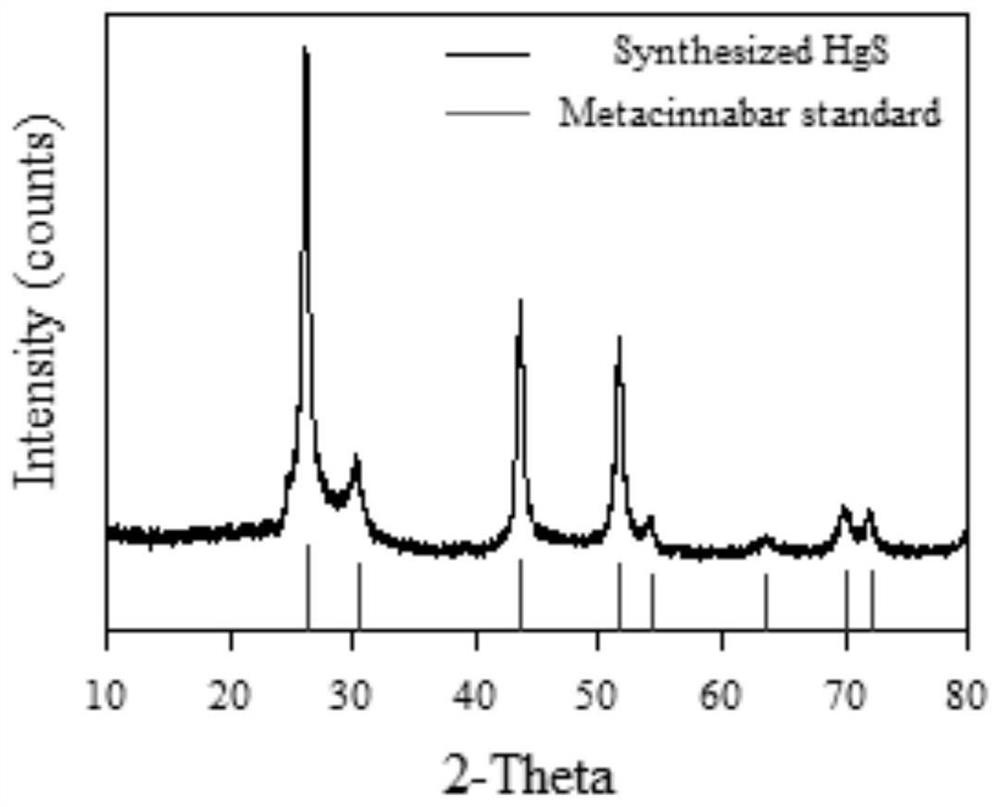

[0025] refer to Figure 1-2 , the preparation method of spherical mercury sulfide nanoparticles adopted in the present invention is a solvothermal synthesis method; mercury nitrate, sulfur powder, and polyvinylpyrrolidone are added to a beaker filled with ethylene glycol, and the beaker is placed in a silicone oil bath at 125 ° C. The oil bath was heated, and at the same time, the mixed solution was reacted for 2 hours with magnetic stirring at a steady speed (10 rpm), and finally mercury sulfide nanoparticles with a size of 30-50 nm were obtained.

[0026] A method for rapidly preparing spherical mercury sulfide nanoparticles, comprising the following steps:

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com