Treatment process of cutting fluid wastewater

A treatment process and cutting fluid technology, applied in the field of cutting fluid wastewater treatment process, can solve the problems of incomplete water treatment steps, high energy consumption, secondary pollution, etc., and achieve excellent COD removal rate and oil removal rate, energy consumption Low, high removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The P(AN-MA) copolymer is self-made, and the preparation method includes the following steps: (1) the water bath is heated up to 60°C, and distilled water is added to a four-necked flask, and N 2 protection; (2) Weigh the emulsifier OP-10 and SDS (CAS No.: 151-21-3) into the four-necked flask and stir evenly, and install the condenser to reflux; (3) Measure the predetermined amount of AN (CAS No.: 107-13-1) and MA (CAS No.: 96-33-3) were mixed evenly, and dodecyl mercaptan (CAS No.: 112-55-0) was added to the four-necked flask; (4) after 1 hour of reaction , add the ammonium persulfate initiator for the first time, and add the mixed solution of AN and MA dropwise into the four-necked flask, control the rate of dropping to 1 drop / s, and the reaction time is 2 to 3 hours; (5) wait for After the dropwise addition is completed, add the ammonium persulfate initiator for the second time, and continue to react for 1 to 2 hours; (6) after the reaction is completed, take out the...

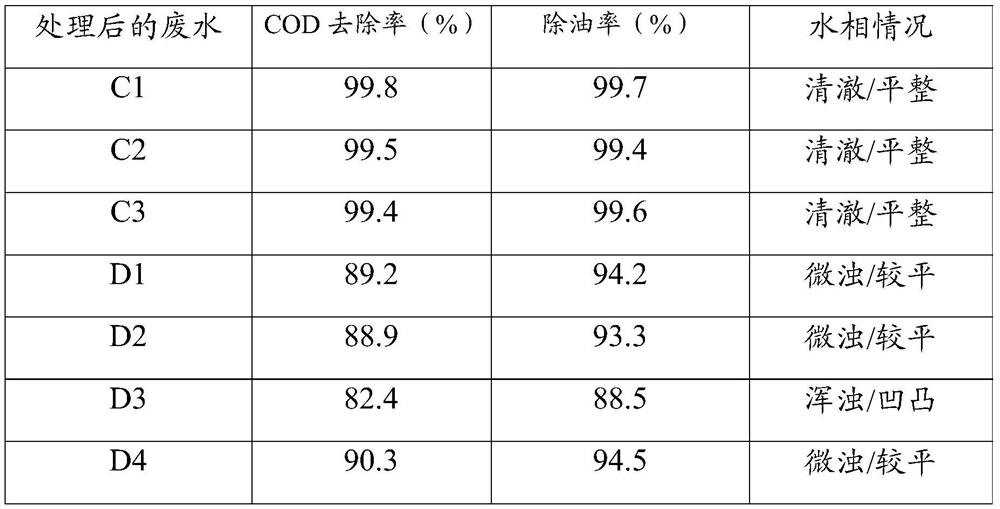

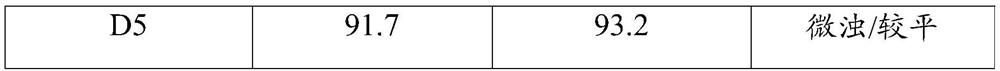

Embodiment 1

[0050] Embodiment 1 provides a cutting fluid wastewater treatment process, including the following steps: 1) Collect the cutting fluid wastewater into a physical sedimentation tank to remove large-sized particles and impurities; (2) evenly flow the wastewater through the electrocatalytic The Phaidon reactor is used for processing, the catalytic voltage is 25V, and the current density is 20mA / cm 2 , the amount of hydrogen peroxide added is 8g / h / L; (3) the treated waste water is passed into the settling tank, and sodium hydroxide is added to adjust the pH to 7.6, and 0.2wt% demulsifier of waste water weight is added to carry out demulsification (demulsifier is composed of cation Polyacrylamide, made by mixing epichlorohydrin-dimethyldiallylammonium chloride polymer and polyoxypropylene polyoxyethylene polyoxypropylene triblock polyether compound, the weight ratio is 1:3:1), After the demulsification is completed, the wastewater passes through the HP (AN-MA) ultrafiltration membr...

Embodiment 2

[0059] The specific implementation mode of this embodiment is the same as that of Example 1, the difference being: in the demulsifier, cationic polyacrylamide, epichlorohydrin-dimethyl diallyl ammonium chloride polymer and polyoxypropylene polyoxyethylene polyoxygen The weight ratio of the propylene triblock polyether compound is 1:2:1. The wastewater treated in this example is denoted as C2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com