A kind of preparation method of o-vanillin spherical crystal

A technology of o-vanillin and spherical crystals is applied in the field of preparation of o-vanillin spherical crystals and achieves the effects of good fluidity, prevention of coalescence and low economic investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

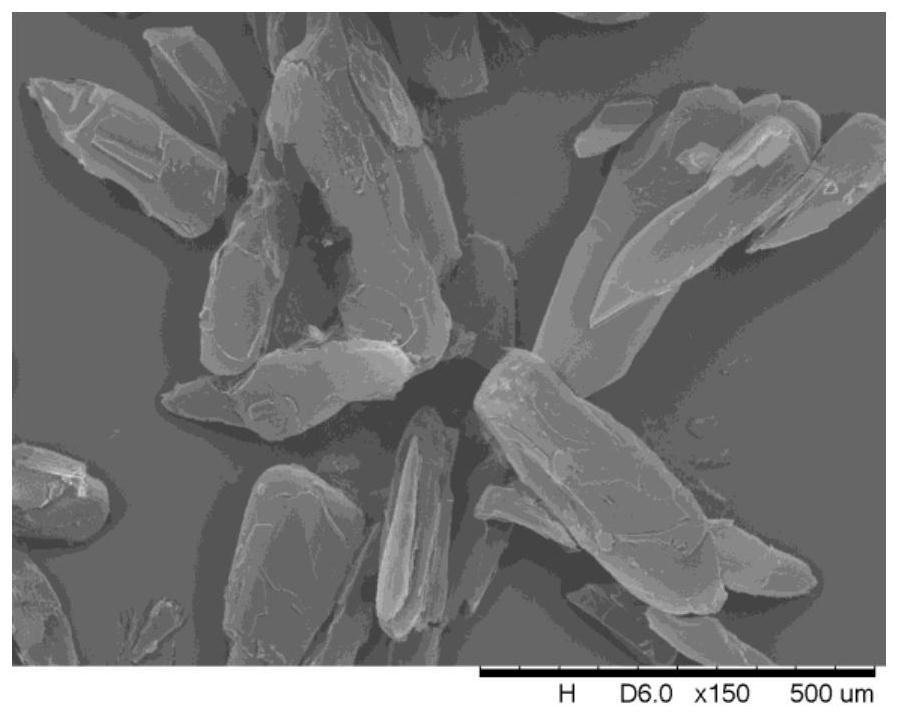

Image

Examples

Embodiment 1

[0030] (1) Prepare 60 mL of a 0.01 g / mL o-vanillin-water mixed solution at 40°C, stir until liquid-liquid phase separation occurs and o-vanillin oil droplets are evenly distributed in the water;

[0031] (2) Cool the solution to 5°C at a cooling rate of 5°C / 1min, maintain a stirring rate of 300rpm until crystallization, and add 0.02% of surfactant sodium stearate (based on the quality of o-vanillin-water mixed solution). Stir continuously for 0.5h to make the crystals coalesce into compact spheres;

[0032] (3) After vacuum filtration, washing with water, and drying at normal pressure at 20° C. for 12 hours, o-vanillin spherical crystals were obtained.

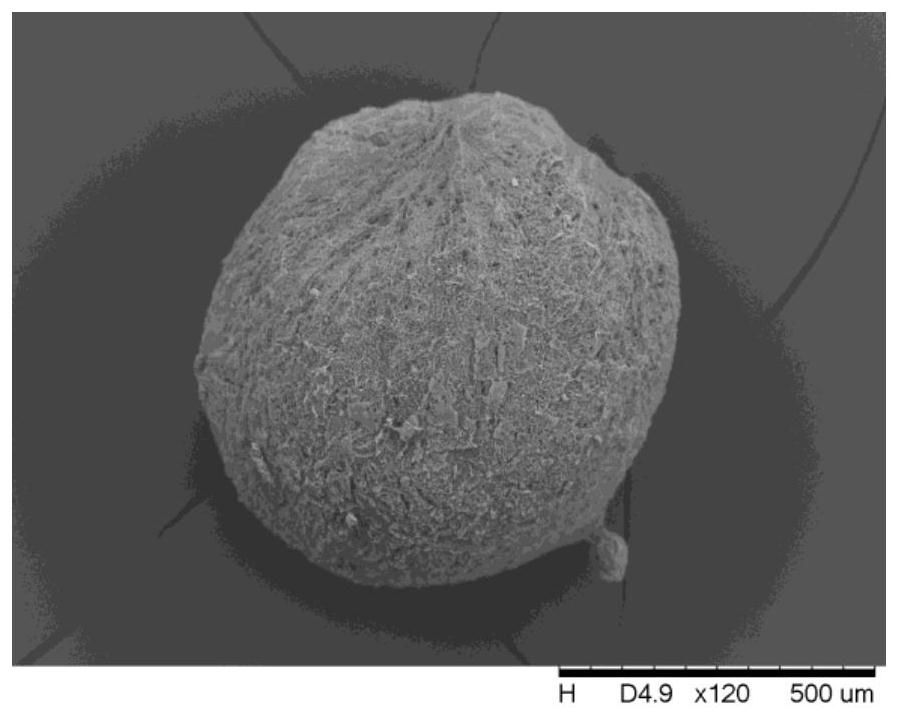

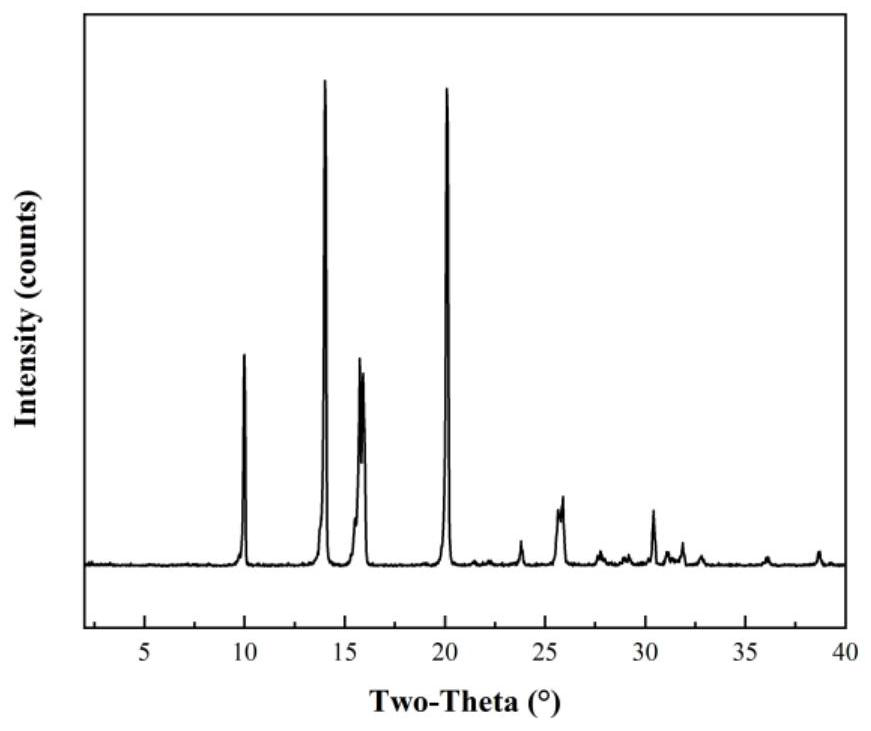

[0033] The XRD pattern of the product is shown in figure 1 , it can be seen that the product is a stable crystal; the average particle size of spherical particles is 300 microns, the angle of repose is 31°, and the tap density is 0.50g / cm 3 .

Embodiment 2

[0035] (1) Prepare 60 mL of a 0.10 g / mL o-vanillin-water mixed solution at 45°C, stir until liquid-liquid phase separation occurs and o-vanillin oil droplets are evenly distributed in the water;

[0036] (2) Cool the solution to 2°C at a cooling rate of 4.5°C / 1min, maintain a stirring rate of 250rpm until crystallization, and add 0.15% of the surfactant sodium hexametaphosphate (based on the quality of the o-vanillin-water mixed solution). Stir continuously for 2.5 hours to make the crystals coalesce into compact spheres;

[0037] (3) After vacuum filtration, washing with water, and drying at 30° C. under normal pressure for 24 hours, o-vanillin spherical crystals were obtained.

[0038] The XRD pattern of the product is shown in figure 1 , it can be seen that the product is a stable crystal; the average particle size of spherical particles is 500 microns, the angle of repose is 31°, and the tap density is 0.58g / cm 3 .

Embodiment 3

[0040] (1) Prepare 60 mL of a 0.15 g / mL o-vanillin-water mixed solution at 50°C, stir until liquid-liquid phase separation occurs and o-vanillin oil droplets are evenly distributed in the water;

[0041] (2) The solution is cooled to 10°C at a cooling rate of 4°C / 1min, and the stirring rate is maintained at 200rpm to crystallization, and 0.30% of the surfactant sodium dodecylbenzenesulfonate (based on o-vanillin-water mixed solution) is added quality). Continue stirring for 3 hours to make the crystals coalesce into compact spheres;

[0042] (3) After vacuum filtration, washing with water, and drying at normal pressure at 35° C. for 36 hours, o-vanillin spherical crystals were obtained.

[0043] The XRD pattern of the product is shown in figure 1 , it can be seen that the product is a stable crystal; the average particle size of spherical particles is 800 microns, the angle of repose is 33°, and the tap density is 0.55g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com