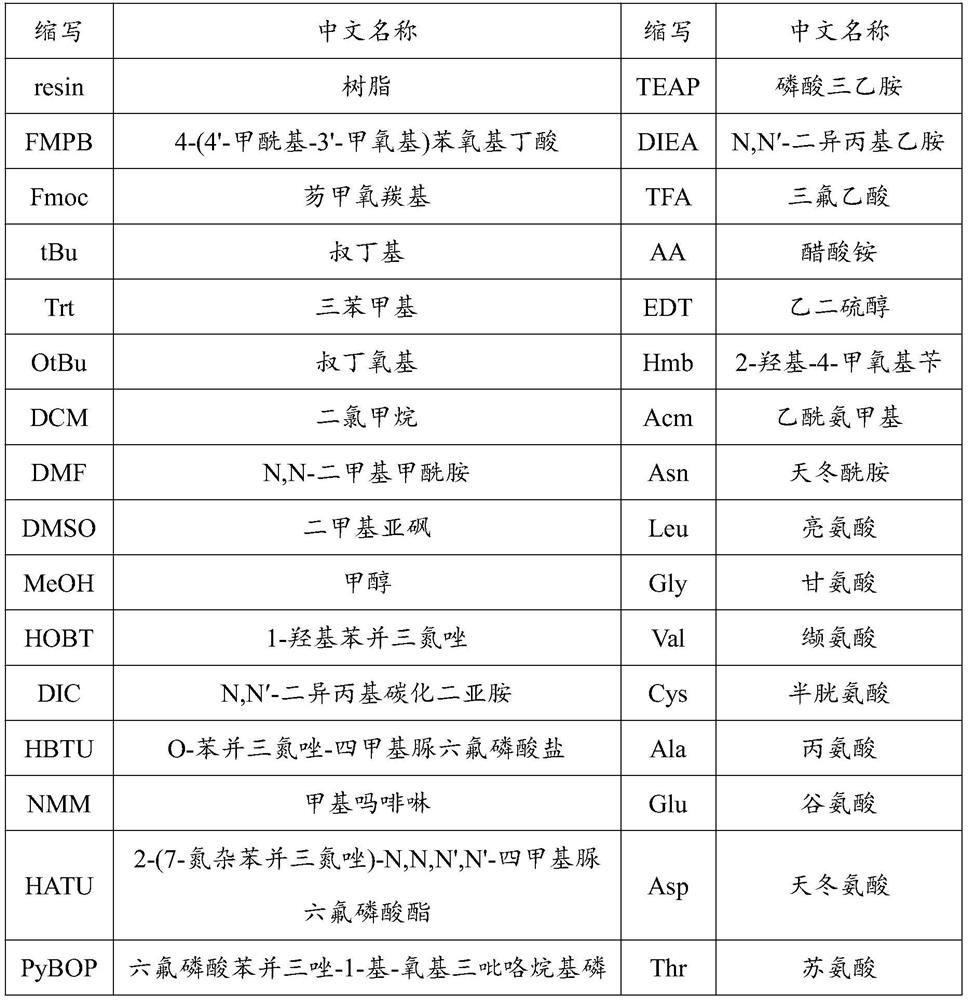

Preparation method of plecanatide

A technology of plecanatide and plecanatide linear peptide, applied in the field of peptide synthesis, can solve the problems of affecting the coupling efficiency of plecanatide, high difficulty of linear peptide synthesis, low purity, etc., and is suitable for industrial production and operation. Simple and easy to reduce the effect of intermolecular disulfide bond formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037]The present invention provides a method for preparing pukanatide, which comprises the following steps:

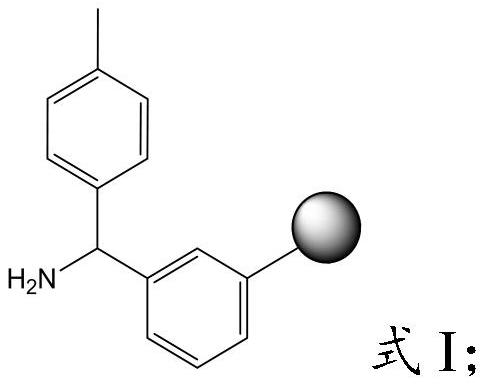

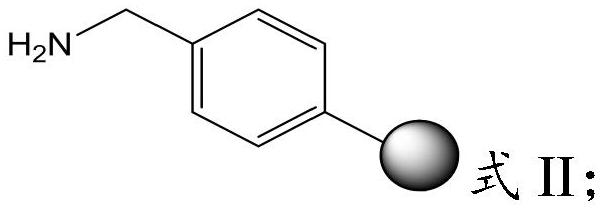

[0038](1) Mix the starting resin, FMPB and the condensation reagent to modify to obtain a modified resin; the starting resin includes MBHA resin or AM resin;

[0039](2) Under a protective atmosphere, the modified resin, H-Leu-OtBu and furan solvents are mixed to carry out the aminoaldehyde condensation reaction, and the obtained Schiff base is mixed with a reducing agent to carry out a reduction reaction to obtain H-Leu -OtBu-FMPB MBHA / AM resin;

[0040](3) Connect Fmoc-Cys(Acm)-OH, R in sequence on the H-Leu-OtBu-FMPB MBHA / AM resin according to the sequence of the pukanatide backbone peptide1-Gly-OH, Fmoc-Thr(tBu)-OH, Fmoc-Cys(Trt)-OH, Fmoc-Ala-OH, Fmoc-Val-OH, Fmoc-Asn(Trt)-OH, Fmoc-Val-OH, Fmoc-Cys(Acm)-OH, R2-Leu-OH, Fmoc-Glu(OtBu)-OH, Fmoc-Cys(Trt)-OH, Fmoc-Glu(OtBu)-OH, Fmoc-Asp(OtBu)-OH and Fmoc-Asn(Trt)-OH, Obtain the fully protected pukanatide resin; the R1And R2Independen...

Embodiment 1

[0117](1) 10g of AM resin with a substitution degree of 1.0mmol / g, 200mL of 5v / v%DIEA / DCM swelling resin for 1h, DMF washed twice, suction filtered to remove the solution, add 3.33g FMPB (15mmol) into the reactor , Add DMF to dissolve, add 2.36mL DIC (15mmol) and 2.03g HoBt (15mmol) to mix, after modification for 1.5h, ninhydrin test becomes negative, wash with DMF 3 times, THF wash 2 times, suction filter to remove the solvent, A modified resin (13.56 g) was obtained.

[0118](2) Under the protection of nitrogen, mix the 1.36g modified resin obtained in step (1), 4.47g H-Leu-OtBu·HCl (20mmol), 200mL THF, add 2.3mL (40mmol) of acetic acid and mix evenly. Aldehyde condensation reaction for 30min, add 3mL of 13.3mol / L sodium cyanoborohydride / methanol solution and mix, reduce reaction for 16h, wash 3 times with DMF, wash 3 times with methanol, and vacuum dry to obtain H-Leu-OtBu FMPBAM resin (1.49 g, yield 96.3%).

[0119](3) Put 1.49g of the H-Leu-OtBu-FMPB AM resin (1mmol) obtained in step...

Embodiment 2

[0127](1) Put 6.30g of the H-Leu-OtBu-FMPBAM resin (1mmol) obtained in step (2) of Example 1 into 25mL DCM to swell for 30min, use 3mmol DIC and 3mmol HoBt as condensation reagents, and swell the swollen H-Leu- OtBu-FMPB AM resin and Fmoc-Cys(Acm)-OH are coupled to react at room temperature, and the end of the reaction is determined by the ninhydrin detection solution. The test result is negative, and then exists in 140mL 20v / v% piperidine in DMF solution The Fmoc protecting group is removed from the bottom, and the end point of the reaction is determined by the ninhydrin detection solution. The test result is positive. The Fmoc protecting group removal reaction is completed to obtain Cys(Acm)-Leu-OtBu-FMPB AM resin; repeat the above coupling reaction React with the removal of the Fmoc protecting group, and connect Fmoc-Hmb-Gly-OH and Fmoc-Thr(tBu)-OH to Cys(Acm)-Leu-OtBu-FMPB AM resin in sequence according to the sequence of the Pukana peptide backbone , Fmoc-Cys(Trt)-OH, Fmoc-Ala-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Volume fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com