Method for pretreatment of flowers and leaves of industrial hemp before supercritical extraction

A cannabis flower, supercritical technology, applied in solvent extraction, separation method, solid solvent extraction and other directions, can solve the problems of affecting extraction efficiency, uneven stacking, low bulk density of flowers and leaves, etc., to ensure the extraction effect and not easy to dust accumulation. , the effect of less fine dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

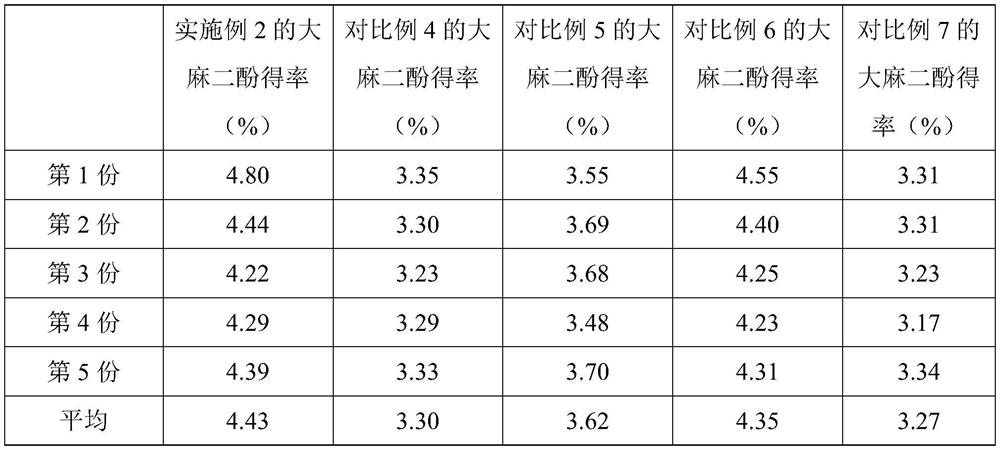

Examples

specific Embodiment approach 1

[0009] Embodiment 1: This embodiment is a pretreatment method before supercritical extraction of industrial hemp flower leaves, which is specifically completed according to the following steps:

[0010] 1. Mixing: first crush the industrial hemp flower leaves to obtain the crushed industrial hemp flower leaves, then add ethanol with a mass fraction of 10% to 20% to the crushed industrial hemp flower leaves, and mix well to obtain the mixed raw material; The mass ratio of crushed industrial hemp flowers and leaves to ethanol with a mass fraction of 10% to 20% is 20:1 to 2;

[0011] 2. Granulation: use the pelletizing machine to make the mixed raw materials into pellets to obtain wet pellets;

[0012] 3. Drying: drying the wet pellets at a temperature of 60-80°C until the moisture content is lower than 8%, to obtain prefabricated pellets of industrial hemp flower leaves.

[0013] In this embodiment, ethanol with a mass fraction of 10% to 20% is used as the binder, and the moist...

specific Embodiment approach 2

[0014] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the moisture content of the industrial hemp flowers and leaves described in step 1 is 8% to 12%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0015] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the particle size of the crushed industrial hemp flowers and leaves in step 1 is 10 mesh to 20 mesh. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com