Method for enriching hafnium tetrachloride by taking crude zirconium tetrachloride as raw material

A technology for enriching hafnium tetrachloride and crude zirconium tetrachloride is applied in the direction of zirconium halide, process efficiency improvement, etc., and can solve the problems of no development of extraction and enrichment of hafnium, low production capacity, large construction investment, etc. Meet the various needs of the market, improve the quality and grades, and improve the effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

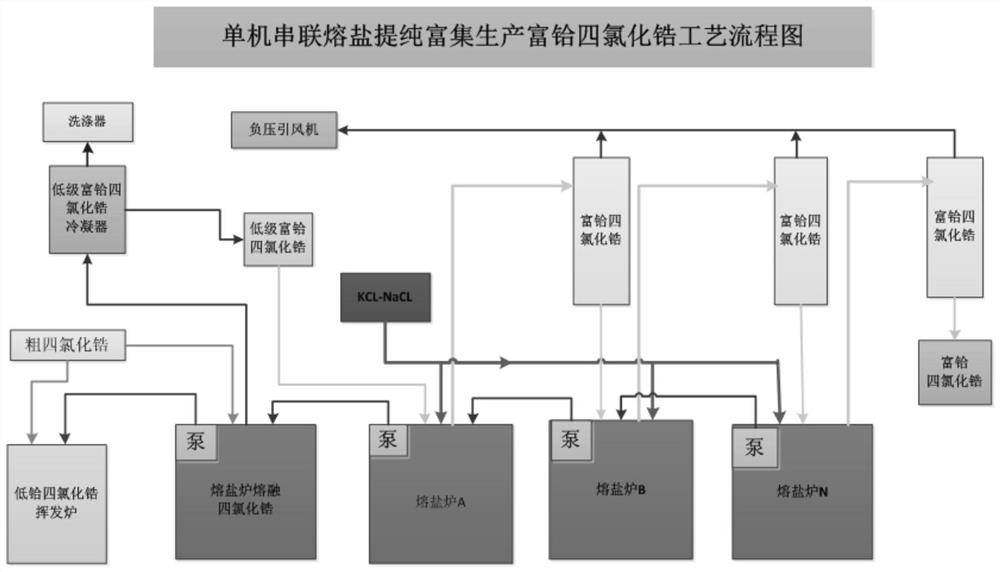

Image

Examples

Embodiment 1

[0024] (1) Extract primary hafnium-rich zirconium tetrachloride raw material

[0025] a. Ingredients: first, KCl and NaCl are mixed according to the molar ratio of 1:1 to prepare alkali metal chloride; then thick zirconium tetrachloride and alkali metal chloride are mixed according to the mass ratio of 85:15;

[0026] b. Molten salt chlorination: Add the mixed salt of crude zirconium tetrachloride and alkali metal chloride salt into the molten salt crucible with stirring, start the power supply of the molten salt heating furnace, heat and stir to melt the mixed salt; Atmospheric pressure control 220°C-250°C;

[0027] c. Extract primary hafnium-rich zirconium tetrachloride: control the appropriate temperature to volatilize zirconium tetrachloride and hafnium tetrachloride in the molten mixed salt in the molten salt crucible, and drive away hydrochloric acid gas and silicon tetrachloride in the gas phase, and enter together A condenser with a water-cooled jacket condenses; ther...

Embodiment 2

[0036] (1) Extract primary hafnium-rich zirconium tetrachloride raw material

[0037]a. Ingredients: first, KCl and NaCl are mixed according to the molar ratio of 1:2 to prepare alkali metal chloride; then thick zirconium tetrachloride and alkali metal chloride are mixed according to the mass ratio of 65:35;

[0038] b. Molten salt chlorination: Add the mixed salt of crude zirconium tetrachloride and alkali metal chloride salt into the molten salt crucible with agitation one after another, start the power supply of the molten salt heating furnace, and heat the mixed salt to melt; Control 320°C-350°C;

[0039] c. Extract primary hafnium-rich zirconium tetrachloride: control the appropriate temperature to volatilize zirconium tetrachloride and hafnium tetrachloride in the molten mixed salt in the molten salt crucible, and drive away hydrochloric acid gas and silicon tetrachloride in the gas phase, and enter together The condenser condenses; therefore when P HfCL4> P ZrCL4 And...

Embodiment 3

[0048] (1) Extract primary hafnium-rich zirconium tetrachloride raw material

[0049] a. Ingredients: first, KCl and NaCl are mixed according to the molar ratio of 1:1 to prepare alkali metal chloride; then thick zirconium tetrachloride and alkali metal chloride are mixed according to the mass ratio of 85:15;

[0050] b. Molten salt chlorination: Add the mixed salt of crude zirconium tetrachloride and alkali metal chloride salt into the molten salt crucible with agitation one after another, start the power supply of the molten salt heating furnace, and heat the mixed salt to melt; Control 270°C-290°C;

[0051] c. Extract primary hafnium-rich zirconium tetrachloride: control the appropriate temperature to volatilize zirconium tetrachloride and hafnium tetrachloride in the molten mixed salt in the molten salt crucible, and drive away hydrochloric acid gas and silicon tetrachloride in the gas phase, and enter together The condenser condenses; therefore when P HfCL4 >P ZrCL4 An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com