Fenbendazole production process and production device

A kind of technology of fenbendazole, production process, applied in the field of fenbendazole production process and production equipment, can solve the problems such as low purity of fenbendazole, low degree of intelligence, waste of reagents, etc., to achieve the improvement of product purity, automation High degree of effect of reducing reagent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

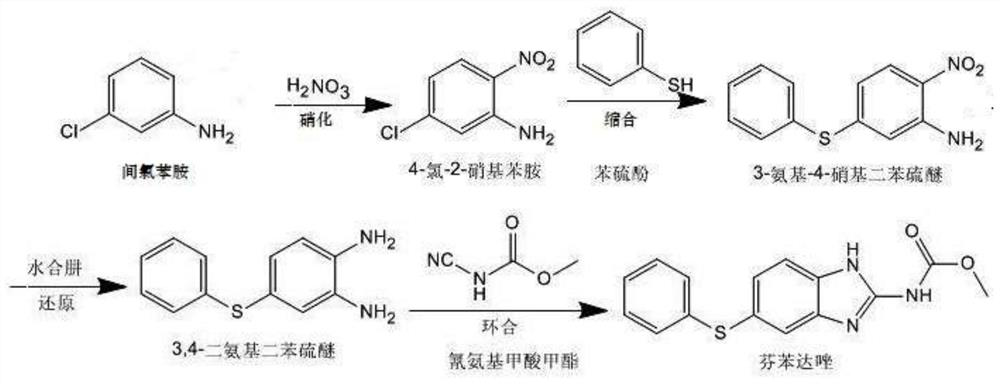

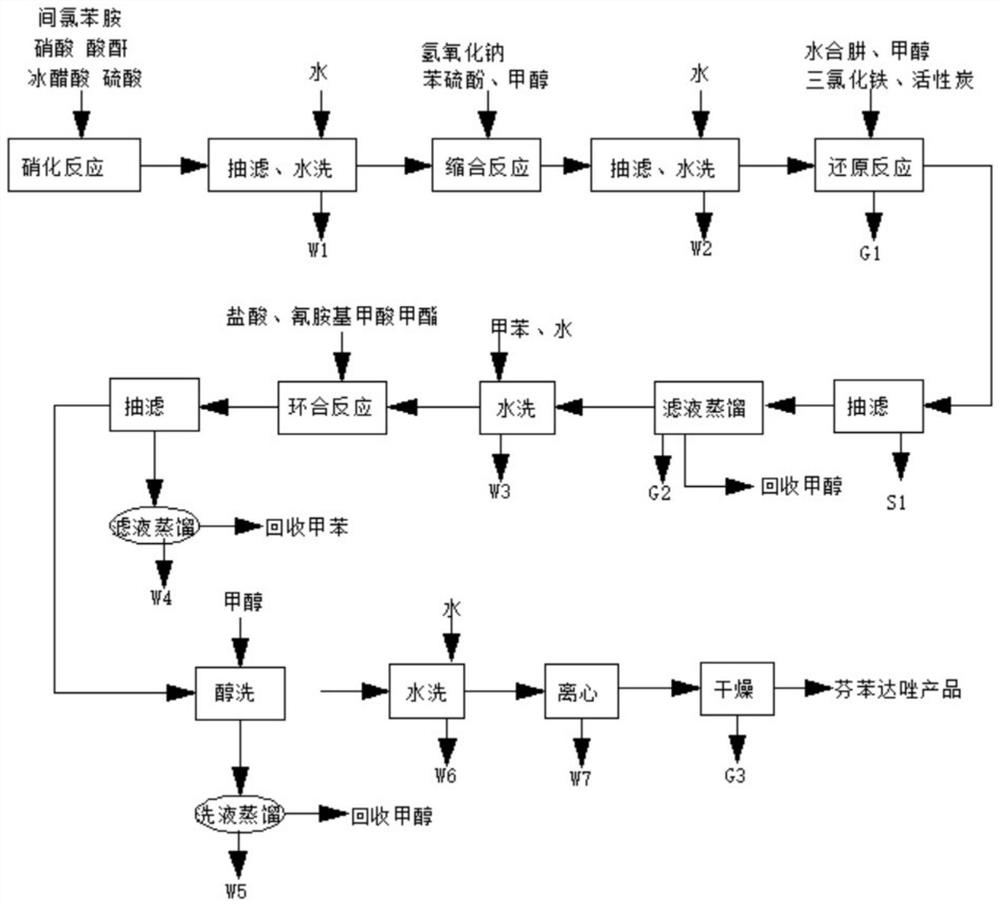

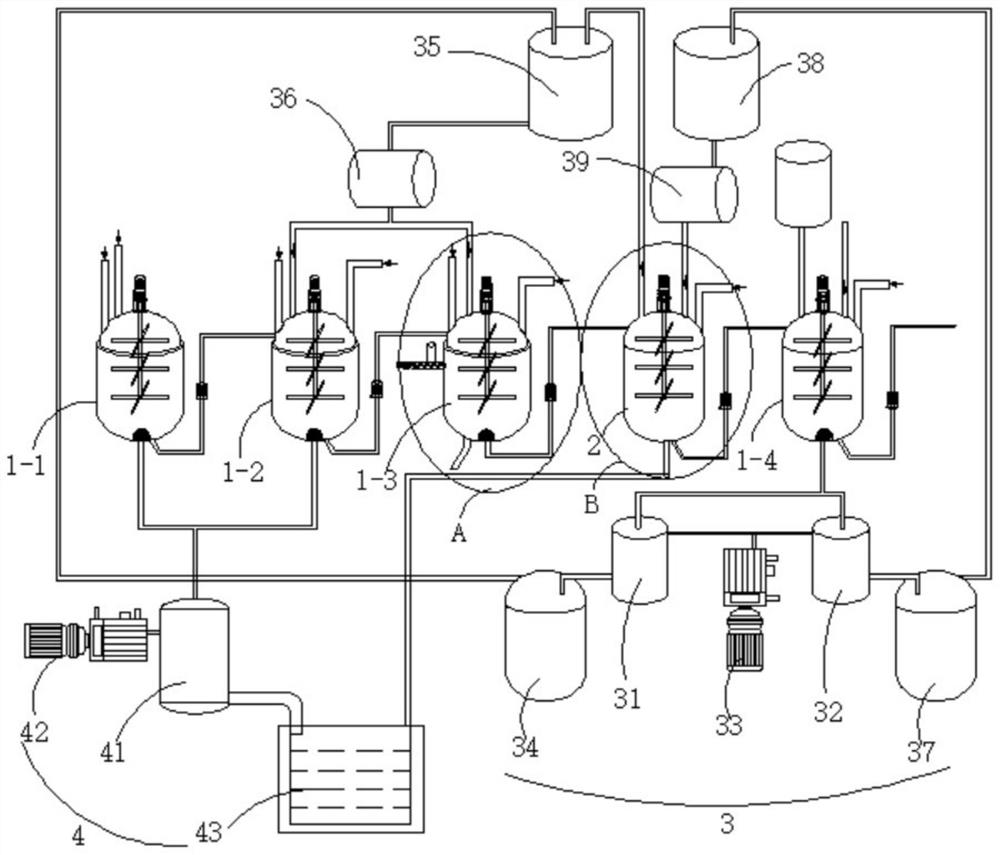

[0036] Such as figure 1 and figure 2 Shown, the fenbendazole production technique of the present embodiment comprises the following steps:

[0037](1) Nitration reaction: Add m-chloroaniline, acid anhydride, glacial acetic acid and sulfuric acid in the nitration reaction kettle, fully stir and mix, then gradually add nitric acid in the nitration reaction kettle, carry out the nitration reaction under stirring, after the reaction finishes, put The mixed solution is transferred to a condensation reaction kettle for solid-liquid separation, then water is added to the solid product for washing, and the washing liquid is separated and treated as waste water to obtain 4-chloro-2-nitroaniline; in the step (1) The nitrification reaction temperature is 10-15°C, and the nitric acid is added within 20 minutes, and the reaction is continued for 3 hours after the addition;

[0038] (2) Condensation reaction: add methanol to the condensation reaction kettle and fully stir and dissolve, t...

Embodiment 2

[0046] Such as figure 1 and figure 2 Shown, the fenbendazole production technique of the present embodiment comprises the following steps:

[0047] (1) Nitration reaction: Add m-chloroaniline, acid anhydride, glacial acetic acid and sulfuric acid in the nitration reaction kettle, fully stir and mix, then gradually add nitric acid in the nitration reaction kettle, carry out the nitration reaction under stirring, after the reaction finishes, put The mixed solution is transferred to a condensation reaction kettle for solid-liquid separation, then water is added to the solid product for washing, and the washing liquid is separated and treated as waste water to obtain 4-chloro-2-nitroaniline; in the step (1) The nitrification reaction temperature is 15-20°C, the nitric acid is added within 25 minutes, and the reaction is continued for 6 hours after the addition is completed; the amount of nitric acid used is m-chloroaniline:nitric acid=1:1.15 in molar ratio.

[0048] (2) Condens...

Embodiment 3

[0057] Such as figure 1 and figure 2 Shown, the fenbendazole production technique of the present embodiment comprises the following steps:

[0058] (1) Nitration reaction: Add m-chloroaniline, acid anhydride, glacial acetic acid and sulfuric acid in the nitration reaction kettle, fully stir and mix, then gradually add nitric acid in the nitration reaction kettle, carry out the nitration reaction under stirring, after the reaction finishes, put The mixed solution is transferred to a condensation reaction kettle for solid-liquid separation, then water is added to the solid product for washing, and the washing liquid is separated and treated as waste water to obtain 4-chloro-2-nitroaniline; in the step (1) The nitrification reaction temperature is 20-25°C, the nitric acid is added within 30 minutes, and the reaction is continued for 10 hours after the addition is completed; the amount of nitric acid used is m-chloroaniline:nitric acid=1:1.2 by molar ratio.

[0059](2) Condensa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com