Preparation method of low-cost coated flame-retardant smoke suppressant

A coating, smoke suppressant technology, applied in flame retardant and smoke suppression, flame retardant material preparation technology field, can solve tin-based flame retardant lack of smoke suppression performance, adverse effects of personnel escape, trapped people died of suffocation and other issues, to achieve the effects of easy industrial production, excellent flame retardant and smoke suppression performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Add 0.01mol of tin tetrachloride and 0.02g of sodium dodecylbenzenesulfonate into a 100mL deionized water beaker containing 20g of nano-calcium carbonate, and sonicate for 20 minutes until completely dissolved;

[0027] (2) Disperse 0.01mol of zinc chloride in 60mL of deionized water, sonicate for 10 minutes until the dispersion is uniform, add the dispersion liquid dropwise into the beaker of step (1), and stir magnetically to make it evenly mixed;

[0028] (3) Dissolve 0.002mol of sodium hydroxide in 10mL of deionized water, sonicate for 10 minutes until completely dissolved, add the solution dropwise into the beaker of step (2), and stir magnetically to make it evenly mixed;

[0029] (4) Put the mixture in step (3) at 50°C for coating reaction for 8 hours, take out the precipitate, wash it with deionized water for 5 times, and dry the product after washing to obtain a low-cost coated flame retardant and smoke suppressant;

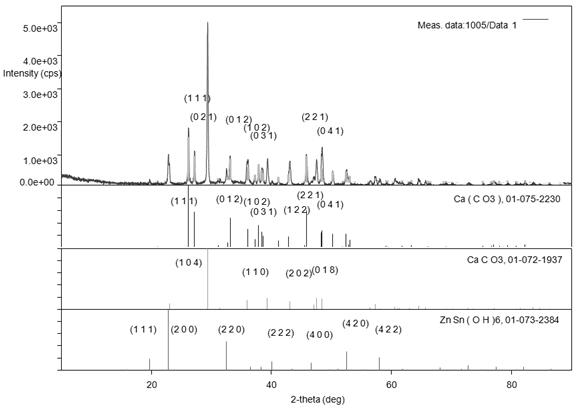

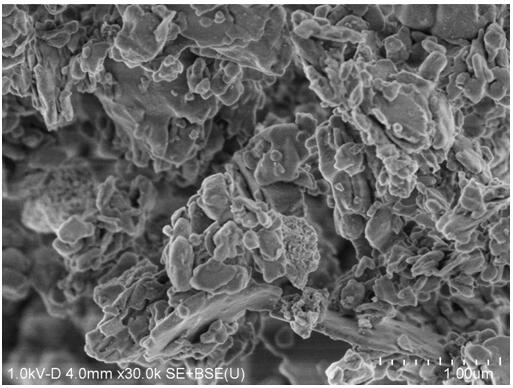

[0030] The X-ray diffraction (XRD) diag...

Embodiment 2

[0033] (1) Add 0.01mol of tin tetrachloride and 0.04g of cetyltrimethylammonium bromide (CTAB) into a 100mL deionized water beaker containing 20g of nano-calcium carbonate, and sonicate for 20 minutes until completely dissolved;

[0034] (2) Disperse 0.002mol aluminum chloride and 0.002mol magnesium chloride in 60mL deionized water, sonicate for 10 minutes until the dispersion is uniform, add the dispersion liquid dropwise into the beaker of step (1), and stir it magnetically to make it evenly mixed;

[0035] (3) Dissolve 0.002mol of potassium hydroxide in 10mL of deionized water, sonicate for 10 minutes until completely dissolved, add the solution dropwise into the beaker of step (2), and stir magnetically to make it evenly mixed;

[0036] (4) Place the mixture in step (3) at 60°C for coating reaction for 6 hours, take out the precipitate, wash it with deionized water for 3 times, and dry the product after washing to obtain a low-cost coated flame retardant and smoke suppressa...

Embodiment 3

[0040] (1) Add 0.01mol tin tetrachloride and 0.02g polyethylene glycol (PEG-2000) into a 100mL deionized water beaker containing 20g nano-calcium carbonate, and sonicate for 20 minutes until completely dissolved;

[0041] (2) Disperse 0.005mol of zinc chloride and 0.005mol of magnesium chloride in 60mL of deionized water, sonicate for 10 minutes until the dispersion is uniform, add the dispersion liquid dropwise into the beaker of step (1), and stir magnetically to make it evenly mixed;

[0042] (3) Dissolve 0.002mol of sodium hydroxide in 10mL of deionized water, sonicate for 10 minutes until completely dissolved, add the solution dropwise into the beaker of step (2), and stir magnetically to make it evenly mixed;

[0043] (4) Place the mixture in step (3) at 70°C for coating reaction for 5 hours, take out the precipitate, wash it with deionized water for 4 times, and dry the product after washing to obtain a low-cost coated flame retardant and smoke suppressant;

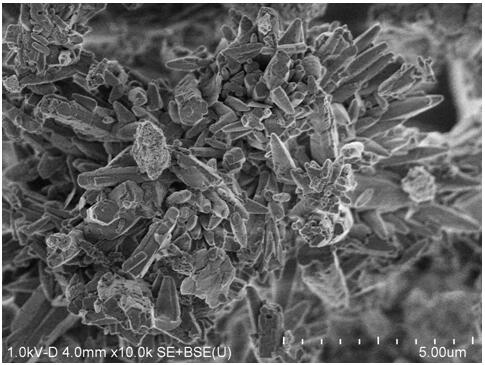

[0044] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com