Double vulcanization system building sealant and preparation method thereof

A technology of sealant and double vulcanization, which is applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of long construction period, construction thickness exceeding a certain thickness, difficult curing, etc., and achieves simple and easy preparation methods Good anti-yellowing performance, beneficial to industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

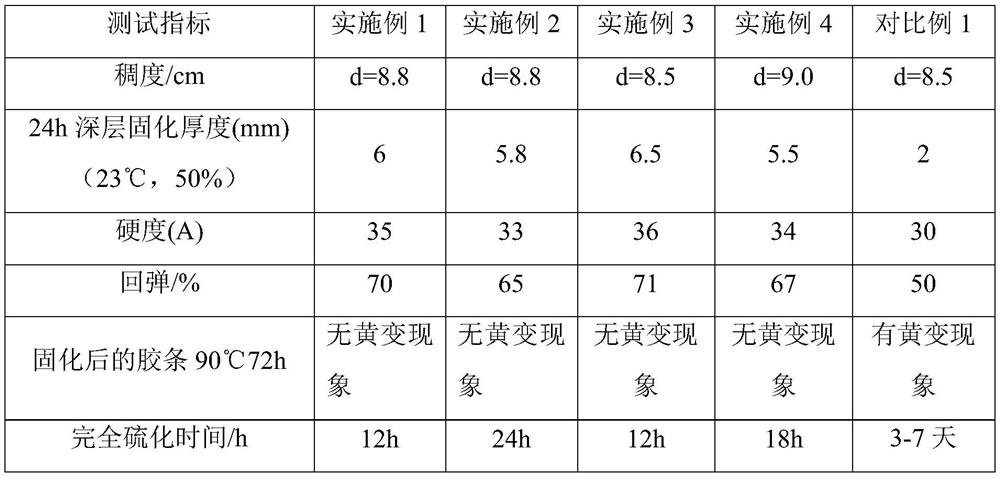

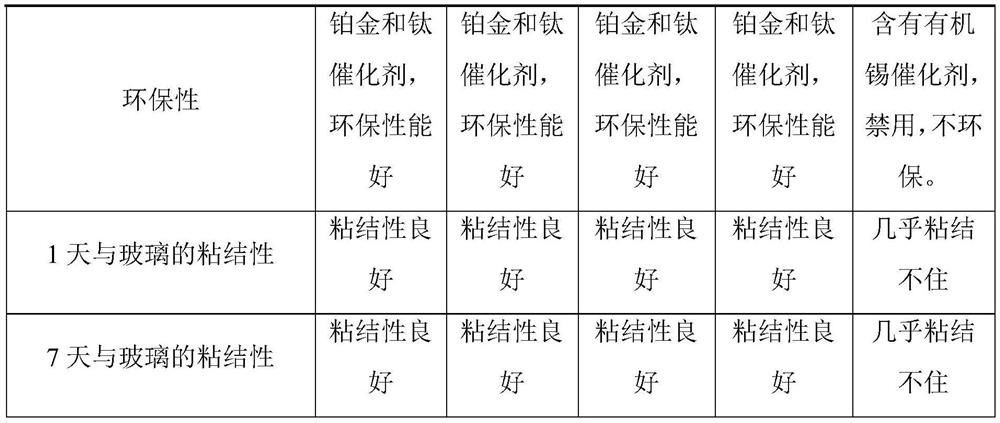

Examples

Embodiment 1

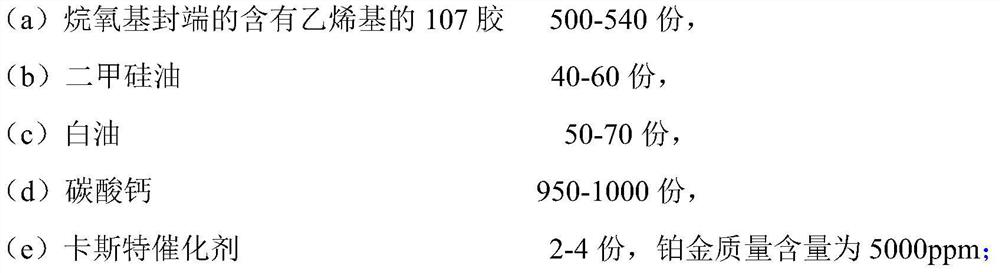

[0036] A kind of dealcoholization type building sealant silicone rubber of double vulcanization system, the raw material mass parts components are as follows:

[0037] A glue component:

[0038] (a) 520 parts of alkoxy-terminated vinyl-containing 107 glue

[0039] (b) 50 parts of dimethicone (viscosity <350cs)

[0040] (c) 60 parts of white oil

[0041] (d) 975 parts of calcium carbonate

[0042] (e) 3 parts of Castel catalyst;

[0043] B glue component:

[0044] (f1) 40 parts of alkoxysilanes containing silicon hydrogen

[0045] (g) 29 parts of titanium catalyst

[0046] (h) 3.2 parts of KH550.

[0047] A glue preparation steps are as follows:

[0048] According to the following proportions, (a) 520 parts of alkoxy-terminated vinyl-containing 107 glue, (b) 50 parts of dimethicone (viscosity <350cs), (c) 60 parts of white oil, (d) 975 parts of calcium carbonate powder Parts (e) 3 parts of Castel catalyst, mixed evenly in a planetary mixer, the vacuum degree is -0.05MP...

Embodiment 2

[0053] A kind of dealcoholization type building sealant silicone rubber of double vulcanization system, the raw material mass parts components are as follows:

[0054] A glue component:

[0055] (a) 520 parts of alkoxy-terminated vinyl-containing 107 glue

[0056] (b) 50 parts of dimethicone (viscosity <350cs)

[0057] (c) 60 parts of white oil

[0058] (d) 975 parts of calcium carbonate

[0059] (e) 3 parts of platinum catalyst;

[0060] B glue components:

[0061] (f2) A mixture of 30 parts of methyltrimethoxysilane and 10 parts of hydrogen-containing silicone oil

[0062] (g) 29 parts of titanium catalyst

[0063] (h) 3.2 parts of KH550.

[0064] A glue preparation steps are as follows:

[0065] According to the following proportions, (a) 520 parts of alkoxy-terminated vinyl-containing 107 glue, (b) 50 parts of dimethicone (viscosity <350cs), (c) 60 parts of white oil, (d) 975 parts of calcium carbonate powder Parts (e) 3 parts of platinum catalyst, 5000ppm are mix...

Embodiment 3

[0070] A kind of dealcoholization type building sealant silicone rubber of double vulcanization system, the raw material mass parts components are as follows:

[0071] A glue component:

[0072] (a) 500 parts of alkoxy-terminated vinyl-containing 107 glue

[0073] (b) 40 parts of dimethicone (viscosity <350cs)

[0074] (c) 50 parts of white oil

[0075] (d) 950 parts of calcium carbonate

[0076] (e) 2 parts of Castel catalyst;

[0077] B glue component:

[0078] (f1) 30 parts of alkoxysilanes containing silicon hydrogen

[0079] (g) 28 parts of titanium catalyst

[0080] (h) KH550 3.0 parts.

[0081] A glue preparation steps are as follows:

[0082] According to the following proportions, (a) 500 parts of alkoxy-terminated vinyl-containing 107 glue, (b) 40 parts of dimethicone (viscosity <350cs), (c) 50 parts of white oil, (d) 950 parts of calcium carbonate powder Parts (e) 2 parts of Custer catalyst, mixed evenly in a planetary mixer, the vacuum degree is -0.05MPa, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com