Electrolyte additive, lithium ion high-voltage electrolyte and lithium ion battery

An electrolyte additive and electrolyte technology, which are applied in the fields of lithium ion high-voltage electrolyte, lithium ion battery, and electrolyte additive, can solve the problems of large limitations of electrode materials, inability to solve the problems of electrode and electrolyte liquid surface oxidation, etc. Instability problem, the effect of improving the diffusion rate of lithium ions, and improving the oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention has no special requirements for the preparation method of the lithium ion high-voltage electrolyte, and only needs to mix the components of the high-voltage electrolyte of the lithium battery uniformly. Then mix the above electrolyte additives evenly.

[0039] The invention provides a lithium ion battery, comprising a positive electrode, a negative electrode, a diaphragm and an electrolyte, characterized in that the electrolyte is a lithium ion high-voltage electrolyte.

[0040] Preferably, the active material of the positive electrode material can be selected from a composite lithium metal oxide containing three elements of nickel, cobalt and manganese, wherein the composite lithium metal oxide can be LiNi 0.5 mn 1.5 o 4 , Li 1.17 Ni 0.25 mn 0.58 o 2 、LiCoO 2 / Li or LiMn 2 o 4 .

[0041] The active material in the negative electrode material can be selected from at least one of lithium metal and lithium alloy.

[0042]

Embodiment 1

[0044] (1) Preparation of electrolyte

[0045] Compound ① is dissolved in the basic electrolyte as an electrolyte additive, wherein the organic solvent in the basic electrolyte is EC / DMC / EMC (volume ratio is 1:1:1), and the lithium salt is 1mol / L LiPF 6 , the addition ratio of compound ① is 0.005%.

[0046] The structural formula of compound ① is as follows:

[0047]

[0048] (2) Preparation of positive pole piece

[0049] Lithium nickel manganese oxide (LiNi 0.5 mn 1.5 o 4 ), conductive carbon black (Super-P) and the binder polyvinylidene fluoride (PVDF) containing N-methyl-2-pyrrolidone (NMP) are mixed according to the mass ratio of 8:1:1, and the ball mill is used for 300r ball milling After 5 hours, the positive electrode slurry was obtained, and the positive electrode slurry was evenly coated on one side of the aluminum foil with a clean surface, dried, and cut into pieces to obtain positive electrode sheets for testing.

[0050] (3) Preparation of button half ce...

Embodiment 2

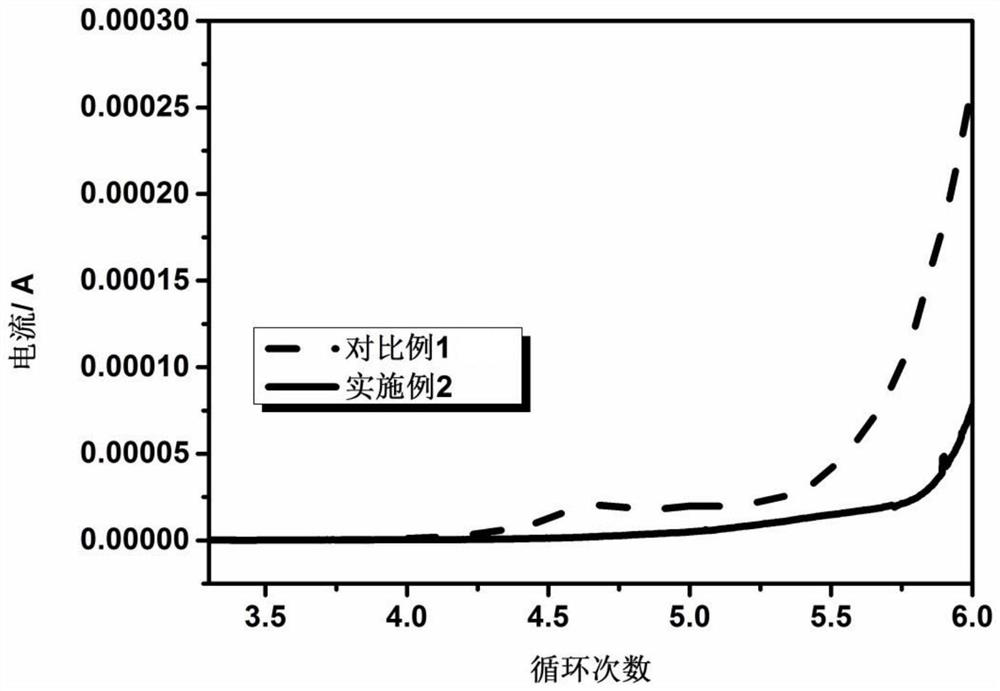

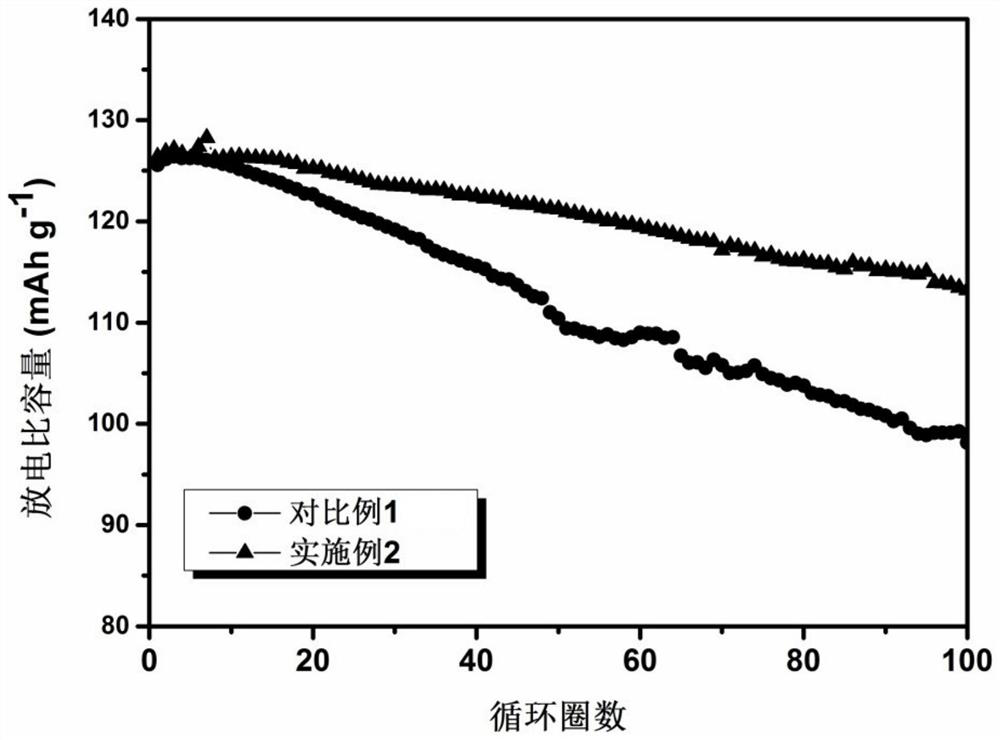

[0055] The difference between this example and Example 1 is that (1) in the preparation of the electrolyte, the addition ratio of compound ① is 0.01%, and the rest of the operations are carried out according to the same steps as in Example 1. Electrode preparation and electrochemical performance test test, obtained The high temperature cycle performance data are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com