Double-layer hydrocolloid dressing and preparation method thereof

A hydrocolloid, double-layer technology, applied in medical science, absorbent pads, bandages, etc., can solve problems such as bonding failure of hydrocolloid dressings, increasing family economic burden, prolonging wound healing time, etc., to improve adhesion stability and Strength, excellent adhesion and liquid absorption properties, widely produced and applied effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Get 10 parts of styrene-isoprene-styrene block copolymer, 45 parts of rubbery elastomer polybutene, 15 parts of petroleum resin (petroleum resin is C5 petroleum resin and C9 petroleum resin according to the quality of 1:1 (obtained by mixing), 5 parts of naphthenic oil, 10101 parts of antioxidant, put into the twin-screw internal mixer, at 130°C, heat-preserve and banbury for 15min; reduce the temperature of the internal mixer to 80°C, add methylol Continue banburying for 45 parts of sodium cellulose for 20 minutes. The resulting product was pressed at 110°C by a flat vulcanizer to form a 1mm plate, which was used as the lower base material of the double-layer hydrocolloid dressing.

Embodiment 2

[0027] Get 20 parts of styrene-isoprene-styrene block copolymer, 35 parts of rubbery elastomer polyisoprene, 12 parts of petroleum resin (petroleum resin is C5 petroleum resin and C9 petroleum resin by 2:1 The mass ratio is obtained by mixing), 5 parts of naphthenic oil, 10101 parts of antioxidant, put into the twin-screw internal mixer, at 120 ℃ temperature, heat preservation and internal mixing for 20min; reduce the temperature of internal mixer to 100 ℃, add hydroxyl Continue banburying 30 parts of sodium methylcellulose CMC and 5 parts of gelatin for 10 minutes. The obtained product was pressed at 100°C by a flat vulcanizer to form a 1mm plate, which was used as the lower base material of the double-layer hydrocolloid dressing.

Embodiment 3

[0029] Get 25 parts of styrene-isoprene-styrene block copolymer, 30 parts of rubbery elastomer polyisobutylene, 8 parts of petroleum resin (petroleum resin is C5 petroleum resin and C9 petroleum resin by mass ratio of 1:2 Mix to obtain), 5 parts of naphthenic oil, 10101 parts of antioxidant, put into the twin-screw internal mixer, at 140 ℃ temperature, insulation banburying 10min; reduce the temperature of internal mixer to 90 ℃, add hydroxymethyl fiber 20 parts of plain sodium CMC and 10 parts of sodium alginate continued banburying for 15 minutes. The resulting product was pressed at 110°C by a flat vulcanizer to form a 1mm plate, which was used as the lower base material of the double-layer hydrocolloid dressing.

PUM

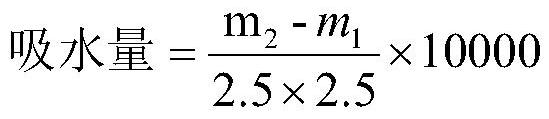

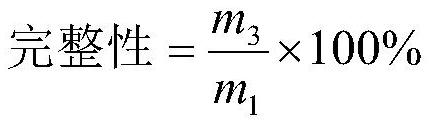

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com