A method and application of waste-free biorefining for preparing porous biochar

A technology of biorefining and biochar, applied in biofuels, chemical instruments and methods, coke ovens, etc., can solve problems such as adverse impacts on the environment and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing porous biochar by non-waste biorefining of succane pithline extraction residue, the specific steps are as follows:

[0026] (1) Preparation of succane pith extraction residue: Add 50g of cane pith and 1000mL of NaOH solution with a concentration of 50g / L into a 3L Erlenmeyer flask. The cane pith was purchased from Yunnan Paper Mill, the same below, for The sugarcane pith is extracted, and the electric heating constant temperature water bath is used at 25°C. The mixture is connected to a 20mm×50cm polytetrafluoroethylene-coated stirring rod, stirred at a speed of 600rpm by a mechanical mixer, and kept for 300min. The treated mixture Compress with a 0.5MPa flat extruder, wash the solid residue with a large amount of deionized water until neutral, and then dry it in an oven at 80°C for 24 hours to obtain the residue;

[0027] (2) Pre-carbonization of sugarcane pith residue: put the sugarcane pith residue obtained in step (1) into the crucible of the ...

Embodiment 2

[0033] A method for preparing porous biochar by non-waste biorefining of succane pithline extraction residue, the specific steps are as follows:

[0034] (1) Preparation of succane pith extract residue: add 50g of cane pith and 1500mL of 200g / L NaOH solution into a 3L Erlenmeyer flask, extract the cane pith, and use electric heating constant temperature water bath at 25 ℃, The mixture is connected with a 20mm×50cm polytetrafluoroethylene-coated stirring rod, stirred at a speed of 600rpm by a mechanical mixer, and kept for 300min. Wash the solid residue until neutral, and then dry it in an oven at 80°C for 24 hours to obtain the residue;

[0035] (2) Pre-carbonization of sugarcane pith residues: put the sugarcane pith residues obtained in step (1) into the crucible of a tube furnace, and use 1 o C / min heating rate to 300 oC Keep for 3h for pre-carbonization;

[0036] (3) Activation of sugarcane pith residue: Weigh 10g of sugarcane pith residue that has been pre-carbonized in...

Embodiment 3

[0040] A method for preparing porous biochar by non-waste biorefining of succane pithline extraction residue, the specific steps are as follows:

[0041] (1) Preparation of succane pith extract residue: add 50g of cane pith and 2000mL of 100g / L NaOH solution into a 3L Erlenmeyer flask to extract the cane pith, and use an electric heating constant temperature water bath at 25 ℃, the mixture is connected with a 20mm×50cm polytetrafluoroethylene-coated stirring rod, stirred at a speed of 600rpm by a mechanical mixer, and kept for 300min. The processed mixture is pressed with a 0.5MPa flat extruder, and a large amount of Wash the solid residue with ionized water until neutral, and then dry it in an oven at 80°C for 24 hours to obtain the residue;

[0042] (2) Pre-carbonization of sugarcane pith residue: put the sugarcane pith residue obtained in step (1) into the crucible of the tube furnace, o C / min heating rate to 500 oC Keep for 2h for pre-carbonization;

[0043] (3) Activat...

PUM

| Property | Measurement | Unit |

|---|---|---|

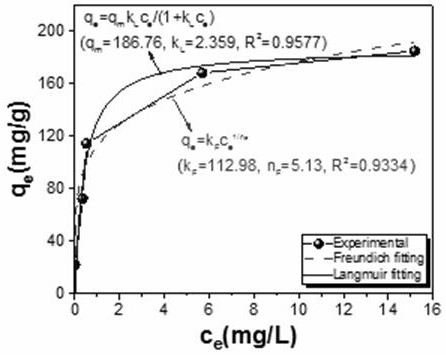

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com