Numerical control combined equipment used for chip manufacturing process

A combined equipment and process technology, applied in other manufacturing equipment/tools, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient chip welding, inconvenient chip engraving, inconvenient smoke cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

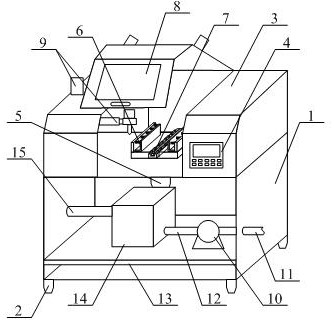

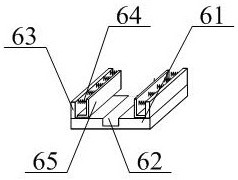

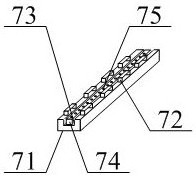

[0036] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, a numerical control combination equipment for chip manufacturing process, including machine bed 1, support legs 2, machine head 3, control panel 4, rotating motor assembly 5, buffer clamping protective seat structure 6, can support and fix the welding frame Structure 7, rotatable adsorption cover structure 8, rotatable plug-in engraving seat structure 9, suction fan 10, first connecting pipe 11, delivery pipe 12, fixed bottom plate 13, smoke purification box 14 and discharge pipe 15, said The upper ends of the support legs 2 are respectively bolted to the four corners of the lower end of the machine bed 1; the machine head 3 is respectively bolted to the left and right sides of the upper end of the machine bed 1; The middle position on the right side of the front surface; the rotating motor assembly 5 is bolted to the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com