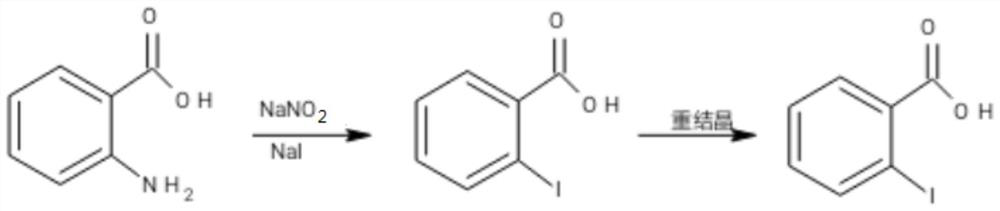

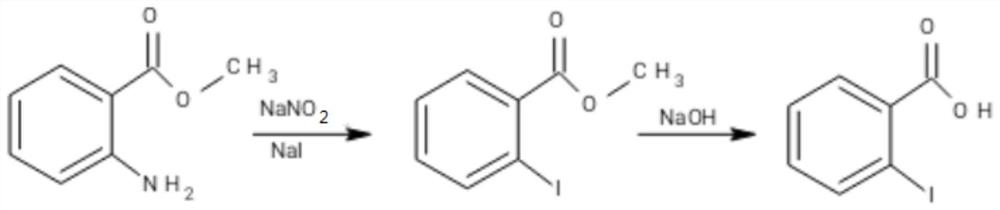

Preparation method of o-iodobenzoic acid

A technology of benzoic acid and o-iodine, which is applied in the field of pharmaceutical synthesis chemistry, can solve problems such as long approval time, high production cost, and production impact, and achieve the effects of unaffected production and operation, convenient production and purchase, and high safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific embodiments and drawings.

[0030] The specific technical scheme is as follows:

[0031] Add 130-145kg of sodium nitrite powder to 40-50kg of water to form a clear solution; add 1400-1500g of water to the reaction flask, then slowly add 250-270kg of concentrated sulfuric acid solution into the reaction flask, and stir evenly to obtain Diluted sulfuric acid solution; finally, add 270-280kg of methyl anthranilate liquid into the diluted sulfuric acid solution, stir and cool down to below 0°C, add the pre-configured sodium nitrite aqueous solution dropwise, and control the The reaction temperature is not higher than 5°C. When the solution gradually becomes clear during the dropping process, and the color changes from red to yellow, the dropping is completed. After the dropping is completed, keep warm for 2 hours and store at low temperature for later use; add 600-650kg of water, Heat 4-5kg ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com