Non-ionized PBI/PVP membrane, preparation method thereof and flow battery

A non-ionized, film-casting liquid technology, used in fuel cells, non-aqueous electrolytes, regenerative fuel cells, etc., can solve the problems of high ionic conductivity, poor ion selectivity, poor ionic conductivity, etc., and achieve high ionic conductivity. , excellent performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of non-ionization PBI / PVP membrane, its preparation method comprises the following steps:

[0035] Step A: Preparation of PBI / PVP casting solution:

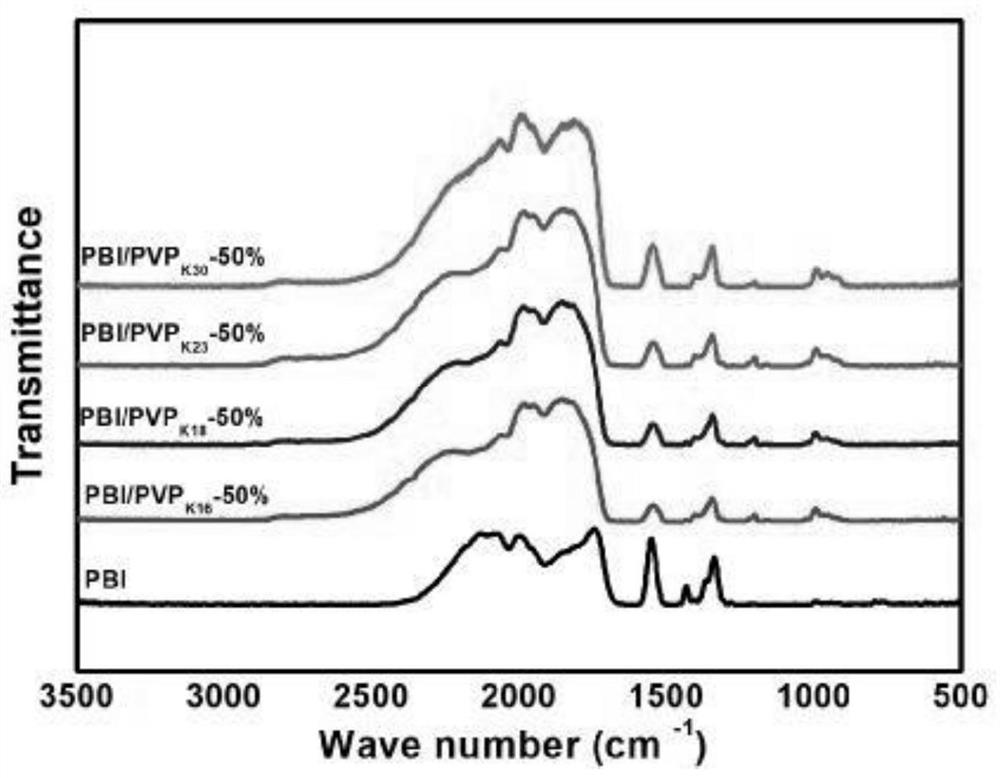

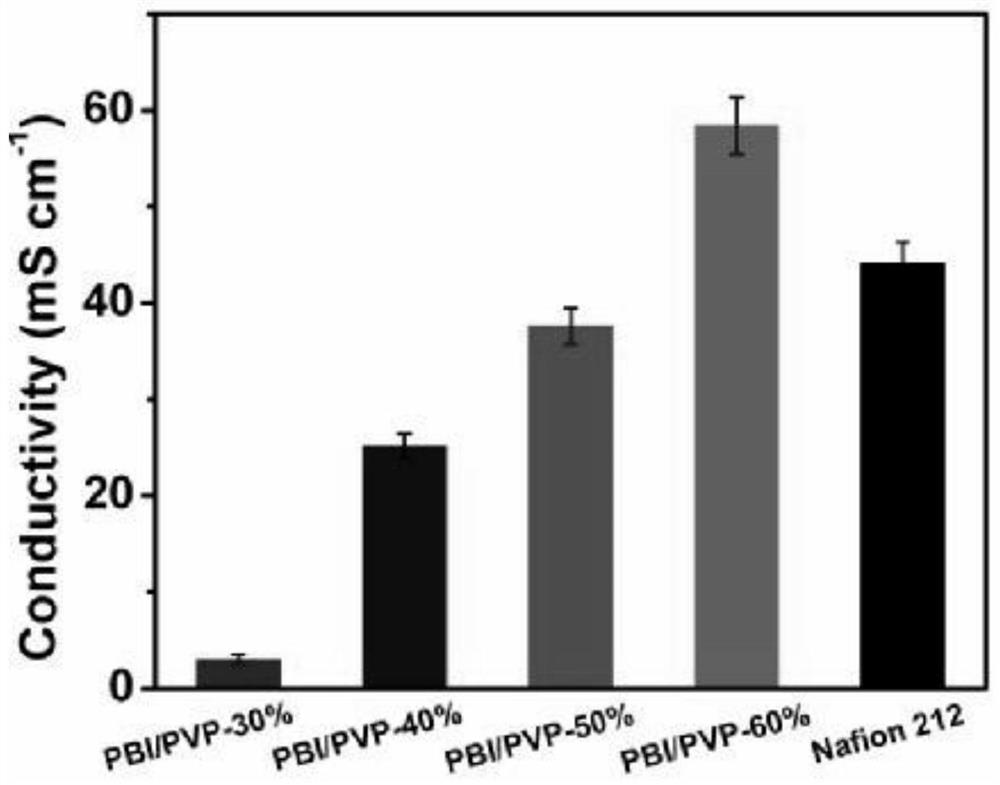

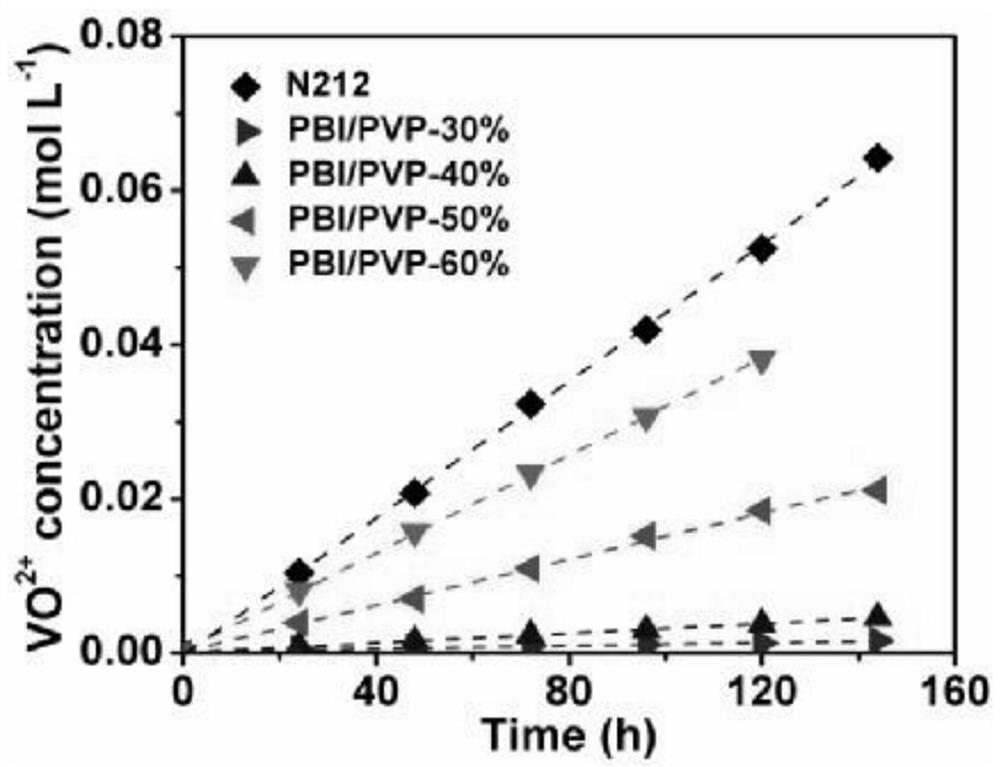

[0036] Add 0.5g PBI / PVP to a 50ml beaker equipped with a stirring device K30 -30% and 20ml N,N-dimethylacetamide, x is 30% refers to PVP K30 quality score;

[0037] Heat and stir at 20°C for 6 hours to dissolve the polymer to form a uniform and transparent PBI / PVP polymer solution;

[0038] After the PBI / PVP polymer solution is cooled to room temperature, air bubbles and insoluble matter are removed after suction filtration to obtain a PBI / PVP casting solution;

[0039] Step B: Film Formation:

[0040] The PBI / PVP film casting solution in step A is formed into a film by casting method, and heated and dried at 60° C. to obtain the PBI / PVP film.

[0041] This embodiment provides a flow battery, including the above-mentioned non-ionized PBI / PVP membrane.

[0042] The following alternative conditions can be used i...

Embodiment 2

[0047] A kind of non-ionization PBI / PVP membrane, its preparation method comprises the following steps:

[0048] Step A: Preparation of PBI / PVP casting solution:

[0049] Add 0.5g of PBI / PVP to a 50ml beaker equipped with a stirring device K18 -40% and 20ml N,N-dimethylacetamide, x is 40% refers to PVP K18 quality score;

[0050] Heat and stir at 40°C for 6 hours to dissolve the polymer to form a uniform and transparent PBI / PVP polymer solution;

[0051] After the PBI / PVP polymer solution is cooled to room temperature, air bubbles and insoluble matter are removed after suction filtration to obtain a PBI / PVP casting solution;

[0052] Step B: Film Formation:

[0053] The PBI / PVP film casting solution in step A is formed into a film by casting method, and heated and dried at 60° C. to obtain the PBI / PVP film.

[0054] This embodiment provides a flow battery, including the above-mentioned non-ionized PBI / PVP membrane.

[0055] The following alternative conditions can be used ...

Embodiment 3

[0060] A kind of non-ionization PBI / PVP membrane, its preparation method comprises the following steps:

[0061] Step A: Preparation of PBI / PVP casting solution:

[0062] Add 0.5g of PBI / PVP to a 50ml beaker equipped with a stirring device K23 -60% and 20ml N,N-dimethylacetamide polymer, x is 60% refers to PVP K23 quality score;

[0063] Heat and stir at 50°C for 6 hours to dissolve the polymer to form a uniform and transparent PBI / PVP polymer solution;

[0064] After the PBI / PVP polymer solution is cooled to room temperature, air bubbles and insoluble matter are removed after suction filtration to obtain a PBI / PVP casting solution;

[0065] Step B: Film Formation:

[0066] The PBI / PVP film casting solution in step A is formed into a film by casting method, and heated and dried at 60° C. to obtain the PBI / PVP film.

[0067] This embodiment provides a flow battery, including the above-mentioned non-ionized PBI / PVP membrane.

[0068] The following alternative conditions ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com