High-temperature-resistant mucorales and application thereof

A technology of Mucor racemosa and high temperature resistance, which is applied in the application field of microbial fermentation technology, can solve the problems of inability to guarantee quality stability and food safety, high temperature resistance, backward industrial technology, etc. Ensure stability and safety, and the effect of mellow product taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

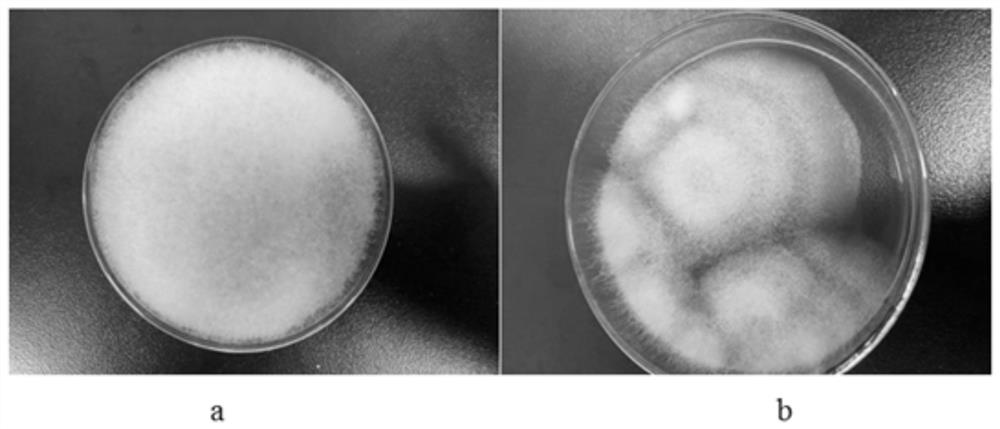

[0041] Screening and isolation of thermotolerant Mucor racemosus M-THF-02

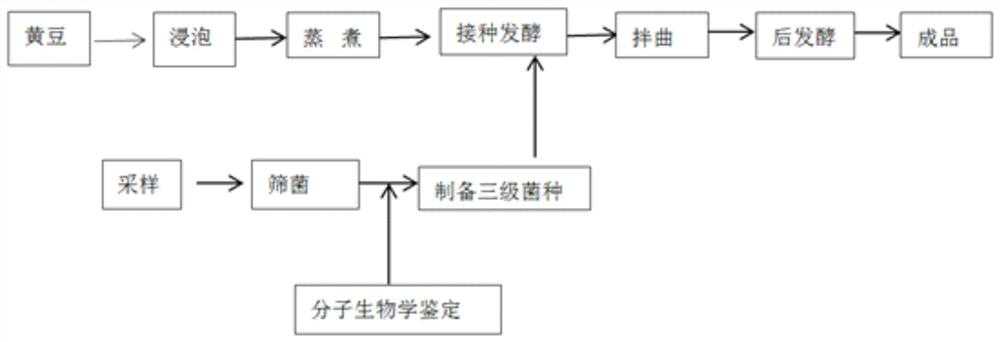

[0042] The purpose of the present invention is to isolate the strains of fermented soya bean koji produced by Chengdu Taihefang Brewing Co., Ltd., address: No. 388, Qingxiang Road, Xinfan Town, Xindu District, Chengdu City, Sichuan Province, production batch number: 20181210; isolate a raceme Mucor M-THF-02, and the isolated Mucor racemosa is made into a third-grade strain for application in fermented soybean meal, thereby shortening the fermentation cycle, improving its nutritional content and production efficiency, and ensuring the controllability of the product Sex, thereby reducing the risk of the product.

[0043] 1. Screening of strains

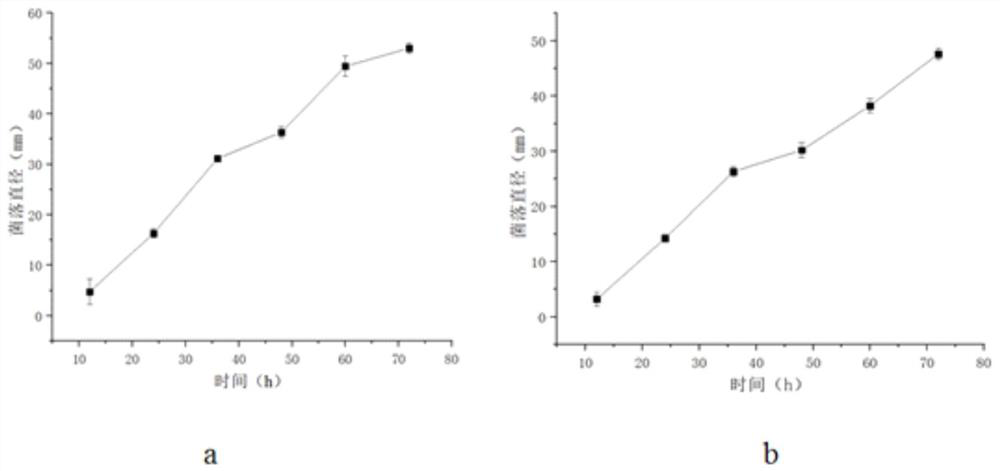

[0044]Add physiological saline one by one from 150 samples for dilution, and select a dilution gradient of 10 -2 、10 -3 Spread the sample dilution on a PDA plate and incubate at 28°C for 48-72 hours, pick and select vigorously growing colonies, and inoculate ...

Embodiment 2

[0078] The application of the industrialized production of Douchi of target Mucor racemosus M-THF-02

[0079] 1. Application method

[0080] (1) Insert Mucorus racemosa and THF-02 for production into PDA slant medium under sterile conditions and culture at 28°C for 48-72 hours, until the slant medium is covered with Mucoral spores (gray white or white) Put it in the refrigerator (0-4°C) for later use. Under sterile conditions, use the inoculation loop to take 1-2 loops of the original Mucor test tube, inoculate it into the culture medium of a 500ml triangular flask, and plug it with a cotton plug. Vibrate fully to make the strain contact with the culture medium and mix well to make the secondary strain. Mix the bean dregs and rice flour at a ratio of 1:1 and put them in a dry open bottle, about 80-100g. Close the bottle mouth with a clean cotton plug and kraft paper, put it in a steaming pool, and take it out after 60 minutes under normal pressure. , after taking out the abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com