Mucor racemosus and application thereof

A technology of Mucor racemosa, M-THF-03, applied in fungi, microorganisms, microorganism-based methods, etc., can solve the problems of blockage of koji materials, unsuitable growth, economic losses of production enterprises, etc., to ensure stability and safety. , shorten the post-fermentation time, and ensure the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 is used to illustrate the mutagenesis method of Mucor racemosa M-THF-03

[0033]M-THF-02 was subjected to compound mutagenesis under the condition of 0.6 mg / ml 2% EMS for 30 min, and 10 strains with early transparent circles and larger colony diameters were selected, and were inoculated by spot inoculation. On the re-screened casein medium plate, culture upside down at 32°C for 3 to 7 days, compare the diameter of the transparent circle on the re-screened medium, and measure the diameter of the transparent circle and the colony on the casein medium plate, the results are shown in Table 1 .

[0034] Table 1 Results of strain re-screening

[0035] .

Embodiment 2

[0036] Example 2 Determination of the performance of Mucor racemosa M-THF-03 obtained by mutagenesis

[0037] The strain C-15, which produced a relatively prominent diameter of the transparent circle and the diameter of the colony, was renamed M-THF-03, and then it was identified by molecular biology.

[0038] 2.1 Molecular biological identification of M-THF-03

[0039] DNA extraction: Add about 50-100mg (wet weight) of fungal or bacterial cells resuspended in purified water to the lysis tube, then add 750ul of lysis solution to the lysis tube, add 500ul of lysis solution, and 150ul of KAC , 50ul isopropanol, centrifuged repeatedly for 15min; collect the supernatant, add an equal volume of 70% ethanol, centrifuge for 10min to wait for the water to be lost, then add 0.1×TE30ul, collect the supernatant to obtain the DNA of the target strain.

[0040] PCR amplification: use fungal 18Sr DNA universal primers to PCR amplify ITS1 (5'-TCCGTAGGTGAACCTGCGGAGTT3'ITS4(5'-TCCTCCGCTTATTGA...

Embodiment 3

[0048] Example 3 is used to illustrate the genetic stability verification of bacterial strain M-THF-03

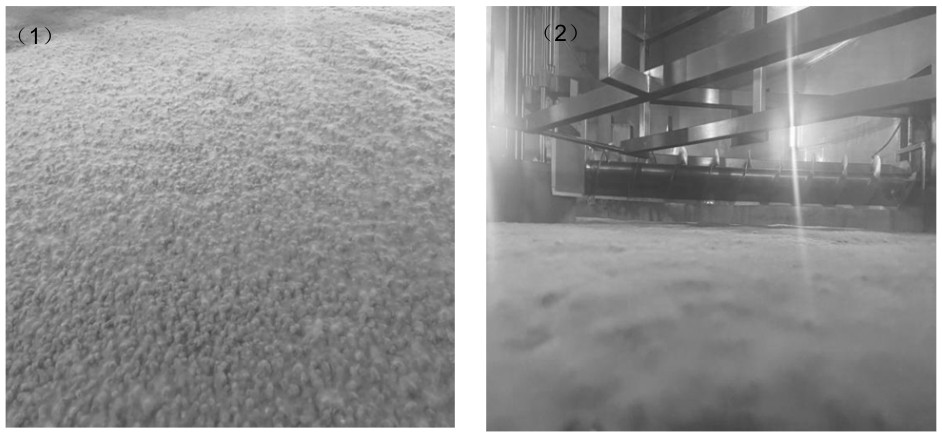

[0049] After more than 10 passages, Mucor M-THF-03 has grown well and has not mutated. According to morphological observation, its texture is loose, opaque, white fluff, hyphae without septa, multinucleated, branched, and its spores are oval shape, spread widely in the culture medium, such as Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com