A kind of MXene reinforced copper-based composite material and preparation method thereof

A technology of copper-based composite materials and body materials, applied in chemical instruments and methods, colloid chemistry, chemical/physical processes, etc., can solve the problems of poor wear resistance and low strength, and achieve excellent mechanical properties, increased strength, and change The effect of interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

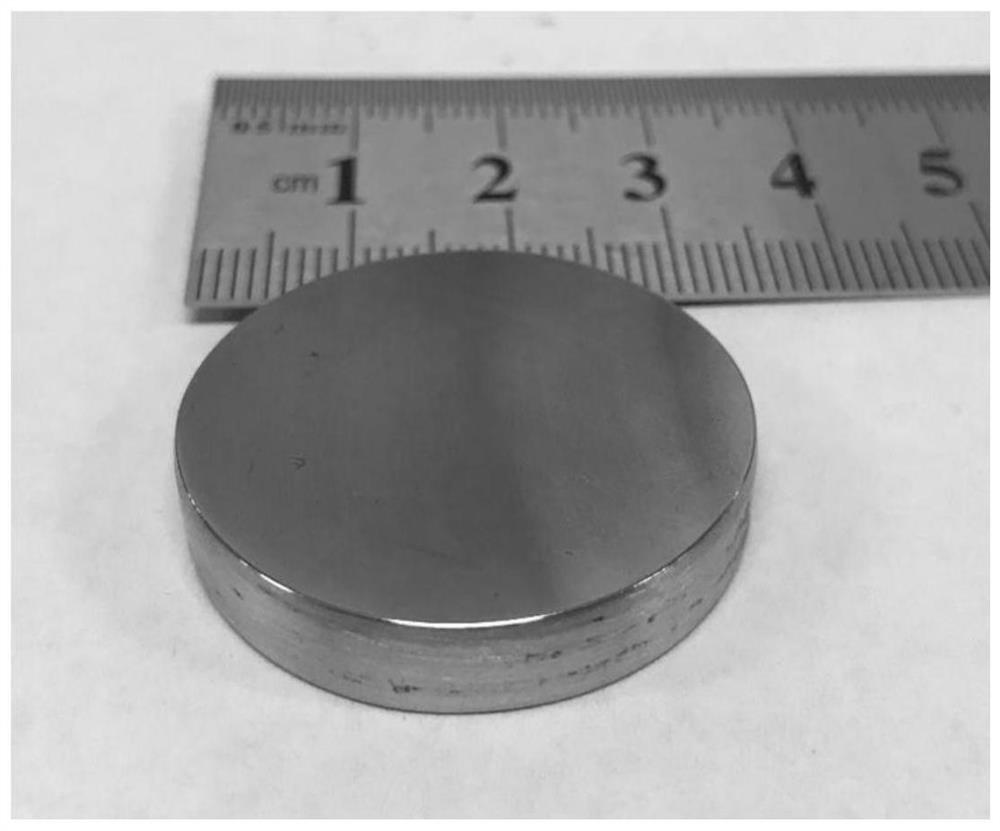

Image

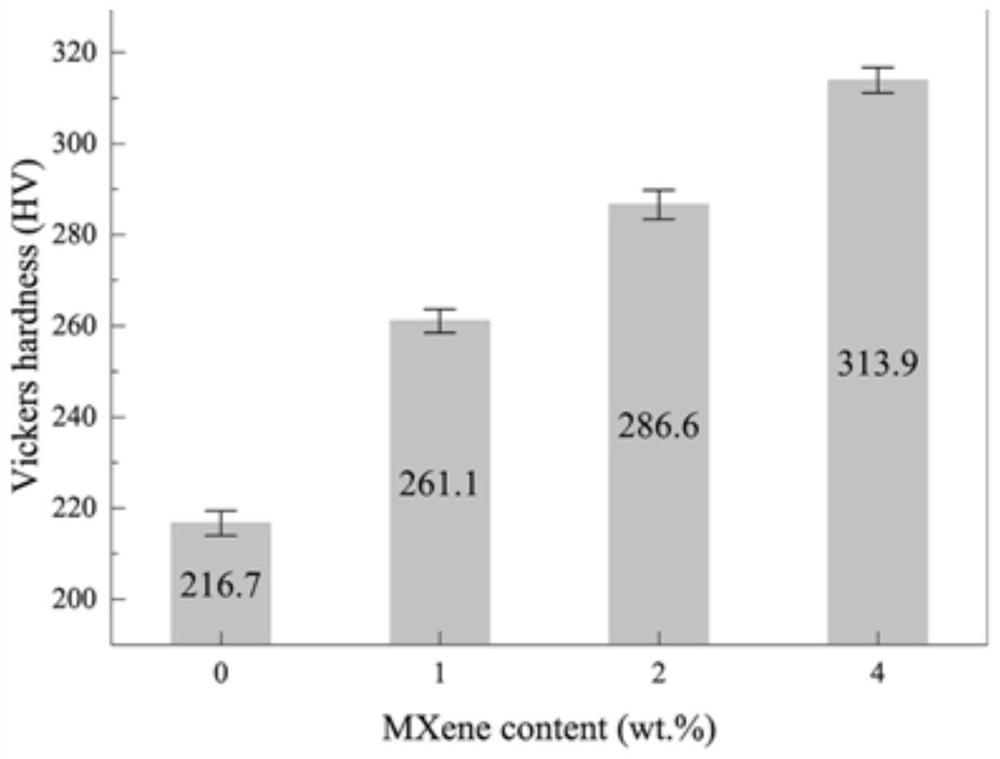

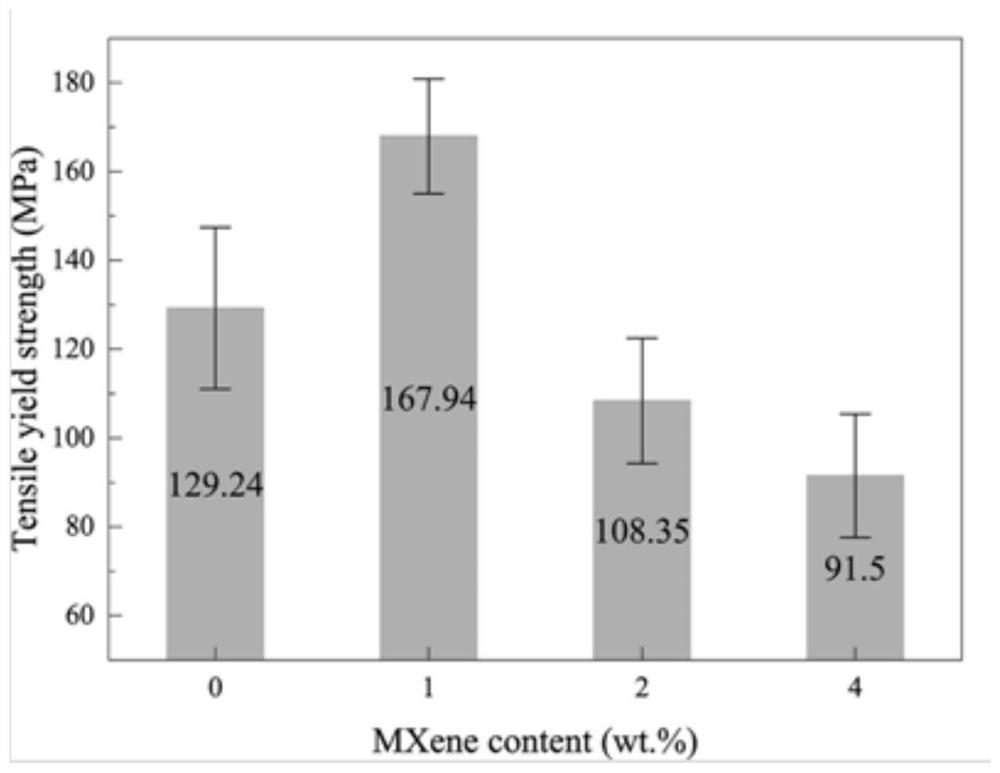

Examples

Embodiment 1

[0035] A kind of preparation method of MXene reinforced copper-based composite material, comprises the following steps:

[0036] 1. Preparation of monolayer MXene:

[0037] (1) After mixing Ti, Al, and C powders according to the molar ratio of 3:1.2:2, high-purity ternary layered Ti was prepared by pressureless sintering at 1500°C 3 AlC 2 ceramic bulk material, the prepared Ti 3 AlC 2 Drilling powder for ceramic material to get Ti 3 AlC 2 Ceramic powder. Prepared Ti 3 AlC 2 The ceramic powder is processed through a 325-mesh sieve;

[0038] (2) 1g of prepared Ti 3 AlC 2 Add 10ml of hydrochloric acid with a concentration of 9mol / ml and 1g of lithium fluoride to the ceramic powder, add a magnetic rotor and stir in an oil bath at 35°C for 24 hours to remove Ti 3 AlC 2 Al atomic layer in

[0039] (3) Wash the corroded mixture suspension with 40ml deionized water and centrifuge, pour off the supernatant, repeat several times until the pH value of the supernatant is grea...

Embodiment 2

[0049] A kind of preparation method of MXene reinforced copper-based composite material, comprises the following steps:

[0050] 1. Preparation of monolayer MXene:

[0051](1) After mixing Ti, Al, and C powders according to the molar ratio of 3:1.2:2, high-purity ternary layered Ti was prepared by pressureless sintering at 1350°C 3 AlC 2 ceramic bulk material, the prepared Ti 3 AlC 2 Drilling powder for ceramic material to get Ti 3 AlC 2 Ceramic powder. Prepared Ti 3 AlC 2 The ceramic powder is processed through a 325-mesh sieve;

[0052] (2) 1g of prepared Ti 3 AlC 2 Add 10ml of hydrochloric acid with a concentration of 12mol / ml and 1g of lithium fluoride to the ceramic powder, add a magnetic rotor and stir in an oil bath at 38°C for 24 hours to remove Ti 3 AlC 2 Al atomic layer in

[0053] (3) Wash the corroded mixture suspension with 50ml of deionized water and centrifuge, pour off the supernatant, repeat several times until the pH value of the supernatant is g...

Embodiment 3

[0063] A kind of preparation method of MXene reinforced copper-based composite material, comprises the following steps:

[0064] 1. Preparation of monolayer MXene:

[0065] (1) After mixing Ti, Al, and C powders according to the molar ratio of 3:1.2:2, high-purity ternary layered Ti was prepared by pressureless sintering at 1400°C 3 AlC 2 ceramic bulk material, the prepared Ti 3 AlC 2 Drilling powder for ceramic material to get Ti 3 AlC 2 Ceramic powder. Prepared Ti 3 AlC 2 The ceramic powder is processed through a 325-mesh sieve;

[0066] (2) 1g of prepared Ti 3 AlC 2 Add 15ml of hydrochloric acid with a concentration of 9mol / ml and 1.6g of lithium fluoride to the ceramic powder, add a magnetic rotor and stir in an oil bath at 35°C for 24 hours to remove Ti 3 AlC 2 Al atomic layer in

[0067] (3) Wash the corroded mixture suspension with 40ml of deionized water and centrifuge, pour off the supernatant, repeat several times until the pH of the supernatant is great...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com