Tungsten oxide alloy material and preparation method thereof

A technology of alloy material and tungsten oxide, which is applied in metal material coating process, nanotechnology for materials and surface science, ion implantation plating, etc., can solve the problems of difficult control of the preparation process, complex preparation methods, and relative density of alloy materials. , Tensile strength and elongation performance are not ideal, to achieve the effect of accelerating the reaction kinetics process, large active surface area, improving electron transport speed and ion diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

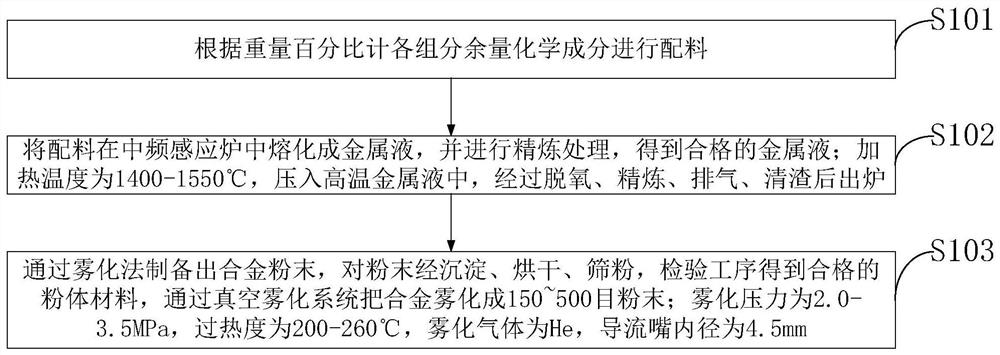

[0058] like figure 1 As shown, the present invention provides a preparation method of a tungsten oxide alloy material, and the preparation method comprises the following steps:

[0059] S101, batching the remaining chemical components of each component according to the weight percentage;

[0060] S102, melt the ingredients into molten metal in an intermediate frequency induction furnace, and carry out refining treatment to obtain a qualified molten metal; the heating temperature is 1400-1550° C., press into the high-temperature molten metal, and undergo deoxidation, refining, exhaust gas, and slag cleaning released later;

[0061] S103, the alloy powder is prepared by atomization, the powder is precipitated, dried, and sieved, and a qualified powder material is obtained through the inspection process, and the alloy is atomized into 150-500 mesh powder by a vacuum atomization system; the atomization pressure is 2.0-3.5MPa, the degree of superheat is 200-260℃, the atomizing ga...

Embodiment 1

[0080] The components of tungsten oxide alloy material are C0.3%, B1.5%, Ni5%, W5%, La0.5%, Ta2.0%, Re2.0%, Mo2.0%, Ti2. 5%, Y 1.0%, K5%, V5, and the balance is iron.

Embodiment 2

[0082] The components of tungsten oxide alloy material are C 0.5%, B2.0%, Ni10%, W10%, La1.5%, Ta2.5%, Re2.5%, Mo2.5%, Ti5%, Y 1.5%, K10%, V10%, and the balance is iron.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com