Fabric material based on silver-containing zeolite and application of fabric material to seawater desalination

A fabric material, silver zeolite technology, applied in seawater treatment, water pollutants, water/sewage treatment, etc., can solve the problems of waste, affecting the yield of desalinated water, etc., and achieve the effect of convenient operation, saving physical strength and time, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

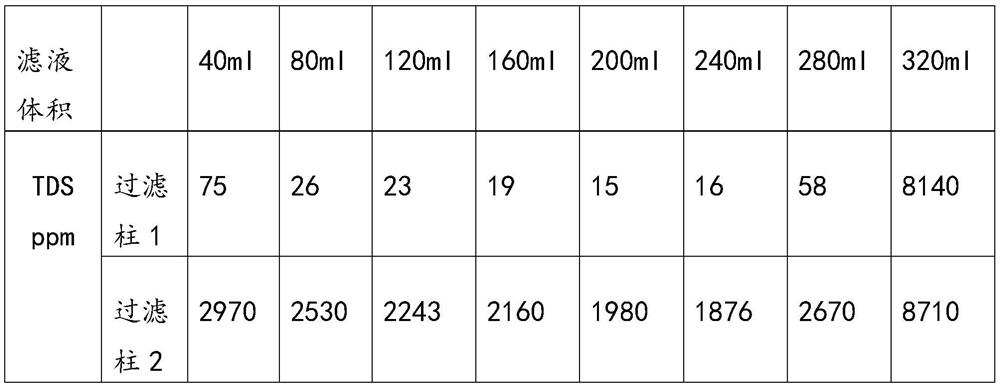

Embodiment 1

[0034] The fabric material based on silver-containing zeolite described in Example 1 includes silver-containing zeolite and fiber fabric, and the silver-containing zeolite is adhered to the fiber fabric by coating and bonding with an inorganic binder. First, the ordinary zeolite powder and the inorganic binder are prepared into a slurry, and then coated on the fiber fabric material by the doctor blade method; after drying and solidification, the zeolite-containing fabric material is soaked in a silver nitrate solution of 0.5 moles per liter. ion exchange. Add a small amount of nitric acid dropwise to the silver nitrate solution to adjust the pH to about 5.0. Ion exchange is carried out under dark conditions, and the treatment temperature is 60 degrees. After 2 hours of exchange, replace with fresh silver nitrate solution, and exchange again. Then wash with deionized water. After drying, the silver-containing zeolite fabric material is prepared. By controlling the coating t...

Embodiment 2

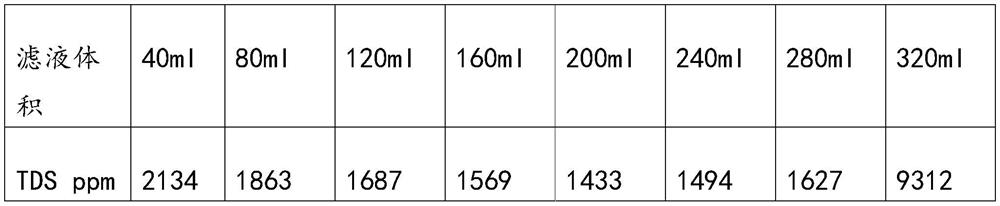

[0037] Example 2 describes a fabric material based on a barium-containing zeolite comprising a barium-containing zeolite and a fiber fabric to which the barium-containing zeolite is attached. First, the surface of the fabric is modified with a silane coupling agent, and then the modified fabric is put into an organic dispersion of zeolite and heated at 90 degrees for treatment. The silanol on the surface of the zeolite reacts with the silanol on the surface of the silane coupling agent, cross-links together, and immobilizes the zeolite on the fiber fabric. Soak the fiber fabric loaded with zeolite in 1 mole per liter of barium chloride aqueous solution for 24 hours. Wash and dry with deionized water to obtain barium-containing zeolite fabric material. The amount of barium-containing zeolite accounts for more than 15% of the total amount of barium-containing zeolite and fiber fabric,

[0038] As a preferred embodiment, the barium-containing zeolite used in this example is cha...

Embodiment 3

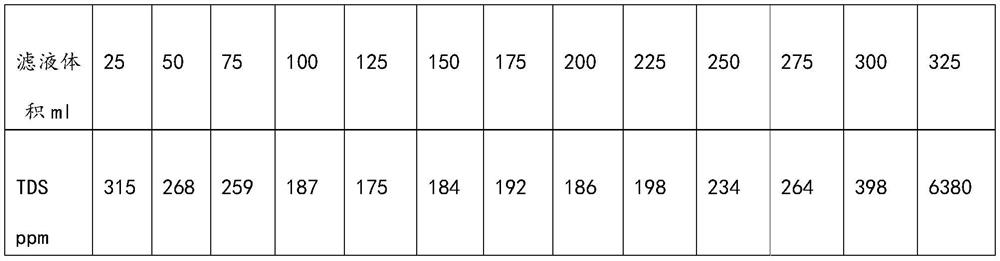

[0040] The fabric material based on silver-containing zeolite described in Example 3 includes silver-containing zeolite and fiber fabric, and the silver-containing zeolite is attached to the fiber fabric. The silver-containing zeolite fabric material used in this example is a zeolite fabric material prepared by in-situ hydrothermal growth. Soak it in a 0.2 mole per liter silver nitrate aqueous solution with a pH value of 5.5, carry out ion exchange under dark conditions, replace the fresh silver nitrate aqueous solution four times within 24 hours, then wash it with ultrapure water and dry it to prepare Silver zeolite fabric. By controlling the reaction conditions, it is ensured that the silver-containing zeolite accounts for more than 15% of the silver-containing zeolite and the total amount of the fiber fabric,

[0041] As a preferred embodiment, the silver-containing zeolite on the fabric material prepared in this example is P-type zeolite, and the molar ratio of silicon at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com