Preparation method and application of polypropylene fibers

A polypropylene fiber, polypropylene technology, applied in the field of water treatment, can solve the problems of reducing equipment service time, reducing coalescing separation effect, increasing pressure drop of coalescer, etc., to improve mechanical and thermal properties, and excellent separation performance. , The effect of preventing stress cracking and warping deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-39 and comparative example 1-22

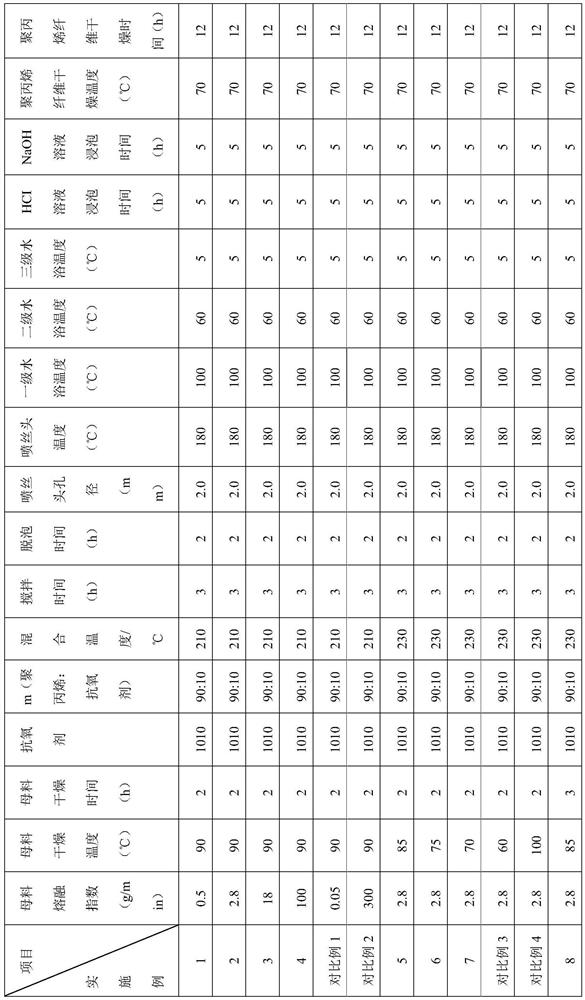

[0067] (1) Take the polypropylene masterbatch for drying treatment, add it to the spinning kettle with a stirring device, mix it with the antioxidant in proportion, heat it to a certain temperature to melt, and stir it under the condition of nitrogen for a certain period of time, after stopping the stirring Let stand for a period of time to defoam, and obtain polypropylene spinning solution.

[0068] (2) After the spinning solution is filtered by the filter screen, the spinning solution is transported to the spinneret by a metering pump, and then the spinning solution melt is extruded at a constant rate to become a polypropylene fiber filament, and the filament is cooled in a three-stage water bath. Afterwards, the polypropylene fiber filaments are collected by winding with a traction wheel.

[0069] (3) The obtained polypropylene fiber is first soaked for a period of time with 0.5mol / L of HCI solution, then soaked for a period of time with 0.5mol / L of NaOH solution, then rins...

Embodiment 40-82 and comparative example 23-48

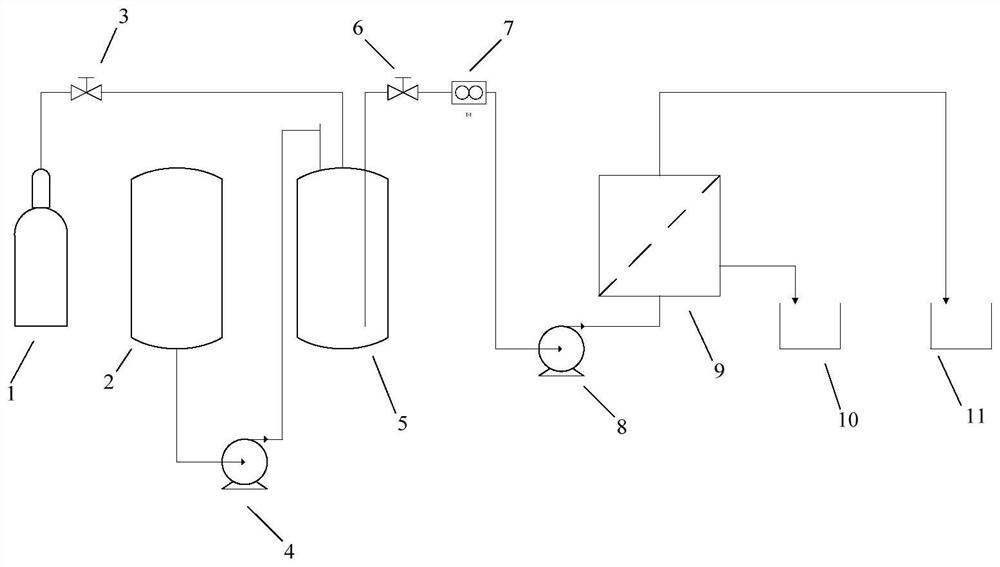

[0076] use figure 1 The shown device treats oily wastewater from a refining and chemical enterprise. The wastewater has a pH of 7.0 and an oil content of 1366mg / L.

[0077] (1) The polypropylene fibers prepared in Examples 1-39 and Comparative Examples 1-23 were packed into the bed of the coalescer in layered compaction, and the filling ratio was 1 / 2.

[0078] (2) Pump the oily sewage with a temperature of 30-50°C in the liquid storage tank into the sewage tank through the sewage pump;

[0079] (3) Open the flow regulating valve, power and pressure regulator valve and air source, pump the liquid in the sewage tank into the coalescer through the feed pump, and control the influent flow at 0.1-0.5m by adjusting the flow regulating valve 3 / h.

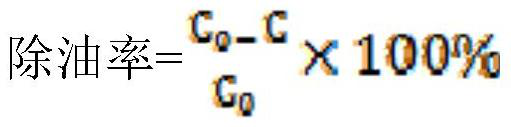

[0080] After the operation is stable, the data is measured and the oil removal rate is calculated.

[0081] The data of each embodiment and comparative example are shown in Table 2.

[0082]

[0083]

[0084]

[0085] Any ref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com