A kind of production method of fulvic acid straw plant fiber degradable plastic film

A technology of plant fiber and degradable mulch film, which is applied in the field of comprehensive utilization of straw resources, can solve the problems of high input cost for planters and insufficient dry and wet strength, and achieve strong operability, mature production and papermaking technology, and good water degradation characteristics and the effect of photodegradation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

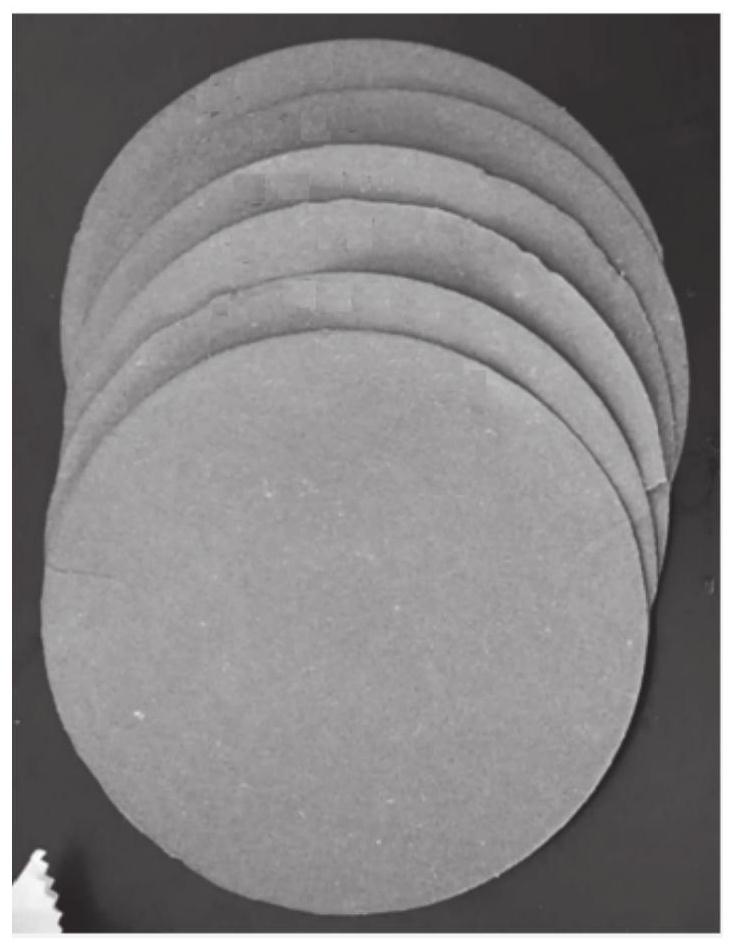

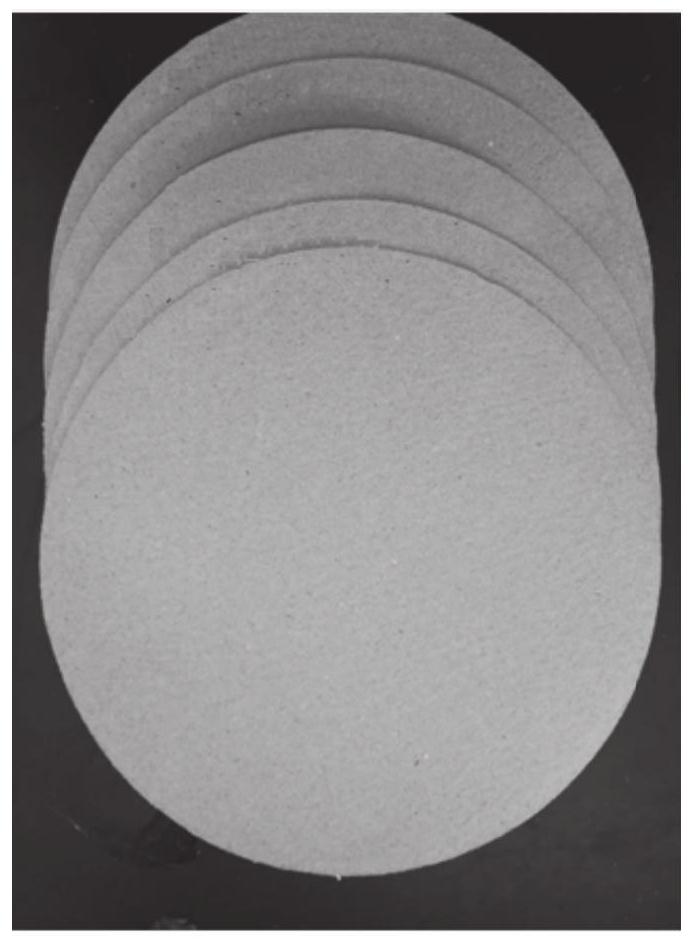

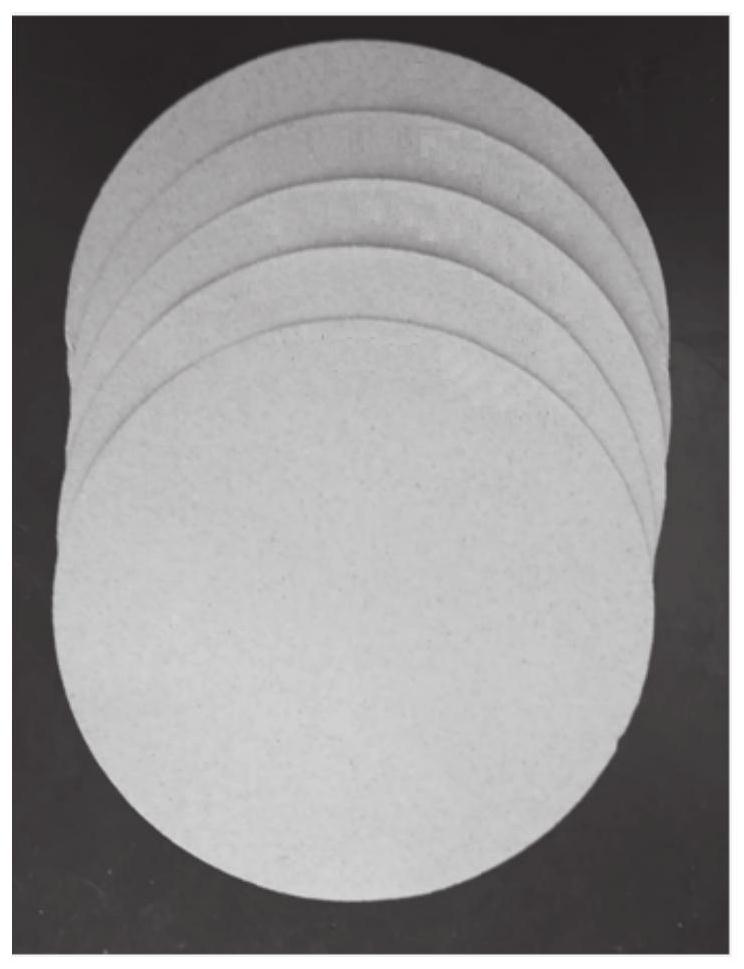

Image

Examples

Embodiment approach

[0057] According to the above ideas for solving the problem, the following solutions are adopted, namely, a method for producing fulvic acid straw plant fiber degradable plastic film, specifically:

[0058] A method for producing fulvic acid straw plant fiber degradable plastic film, which uses straw fiber pulp and fulvic acid as main raw materials to produce fulvic acid straw fiber degradable plastic film, specifically:

[0059] a. Use straw as raw material to produce pulp and fulvic acid;

[0060] b. Deep activation treatment of fulvic acid;

[0061] c. adding the pulp and the deeply activated fulvic acid to a cross-linking agent to carry out a cross-linking reaction to obtain a slurry;

[0062] d. Add wet strength agent and film-forming agent, papermaking and post-treatment according to known techniques;

[0063] e. Removal of hemicellulose.

[0064] Obtained fulvic acid straw fiber degradable plastic film and commercial fulvic acid.

[0065] In some embodiments, stalks...

Embodiment 1

[0076] Using straw as raw material to produce pulp and fulvic acid by ammonium method cooking, specifically,

[0077] The first step is to prepare. Take 1000g of cotton stalks, the raw materials are from the 10th Regiment of the First Division of Alar, Xinjiang Construction Corps, remove the peaches and soil, cut them to 20-30mm, wash and dry them for later use.

[0078] The second step is cooking. Put the raw materials into the ZQS-1 type 15L electric heating rotary cooking pot. Ammonium sulfite addition 15%, H 2 SO 4 The addition amount is 0.1%, the pH is 6.5, the addition amount of the penetrant JFC is 0.01%, and the catalyst CuSO 4 The addition amount is 0.01%, cooking, heating to 120 DEG C to release steam, heating to 165 DEG C, and heat preservation for 90 minutes, the slurry yield is 60%, and the Kappa value is 17.

[0079]The third step is refining and dispersing, obtaining fiber, and extracting fulvic acid. It was decomposed in a 300mm KRK high-concentration mil...

Embodiment 2

[0089] Using cotton straw as raw material to produce pulp and fulvic acid by ammonium method cooking, specifically,

[0090] The first step to the fourth step are the same as in Example 1;

[0091] The fifth step is deep activation of fulvic acid. First, add ammonium sulfite to the fulvic acid concentrated black liquor with a solid content of 50%, and the addition amount is 10% of the solid content of fulvic acid, CuSO 4 The addition amount is 0.1% of the dry basis weight of fulvic acid, the temperature is 90 ° C, and the temperature is kept for 60 minutes; secondly, an activator is added, and the ratio is, catechin: gallic acid: tannic acid = 1: 1: 1, the addition amount is 0.5% by weight of fulvic acid dry basis, CuSO 4 The addition amount is 0.01% of the dry basis weight of fulvic acid, the temperature is 60° C., the temperature is maintained for 90 minutes, and the mixture is stirred.

[0092] The sixth step, cross-linking reaction, specifically, firstly, cellulose and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com