Rollable flexible electrothermal film and manufacturing method thereof

An electrothermal film and flexible technology, applied in the field of rollable flexible electrothermal film and its production, can solve problems such as affecting the thermal conductivity and far-infrared radiation effect of electrothermal film products, complicated electrothermal film manufacturing process, and limiting the use range of the electrothermal film, etc. Conducive to mass production, easy to obtain power supply, good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

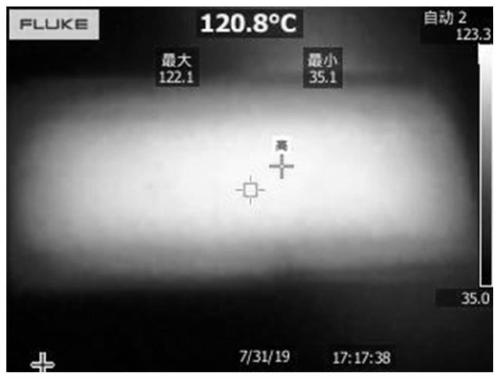

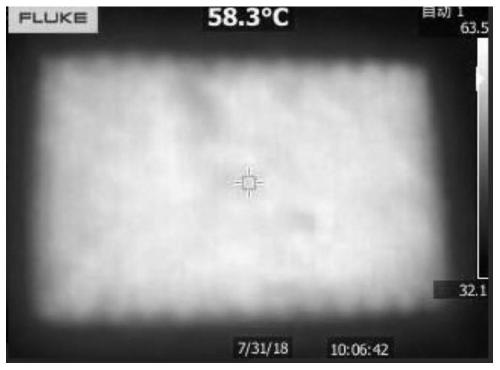

Image

Examples

Embodiment 1

[0037] A rollable flexible electrothermal film comprises the following components by weight percentage:

[0038] Styrene thermoplastic elastomer 70%, graphene and conductive carbon black composite conductive agent 19%, antioxidant 2,6-di-tert-butyl-p-cresol 1%, flow agent ethylene bisstearamide 5% , Petroleum-based plasticizer 4%, surfactant cellulose macromolecule 1%. Wherein, the composite conductive agent is a composite conductive agent of graphene and conductive carbon black, and the mass ratio of graphene: conductive carbon black is 1:1.

[0039] Make it as follows:

[0040] Styrene thermoplastic elastomer, graphene and conductive carbon black composite conductive agent, antioxidant 2,6-di-tert-butyl p-cresol, flow agent ethylene bisstearic acid amide, petroleum-based plasticizer according to the above ratio Melt and knead with surfactant cellulose macromolecules at a high temperature of 200° C. for 1.5 h in a kneading equipment to obtain a mixed jelly-like substance. ...

Embodiment 2

[0046] A rollable flexible electrothermal film comprises the following components by weight percentage:

[0047] Olefin thermoplastic elastomer 62%, graphene and carbon nanotube composite conductive agent 25%, antioxidant 2,6-di-tert-butyl-4-methylphenol 1%, flow agent pentaerythritol stearate 5% , Fatty oil plasticizer 5%, surfactant sugar macromolecule 2%. Wherein, the composite conductive agent is graphene and carbon nanotube composite conduction, and the mass ratio of graphene:carbon nanotube is 1:2.

[0048] Follow the steps below to make the method:

[0049] Olefin-based thermoplastic elastomer, graphene and carbon nanotube composite conductive agent, antioxidant 2,6-di-tert-butyl-4-methylphenol, flow agent pentaerythritol stearate and surfactant sugars were mixed according to the above ratio The macromolecule is melted and kneaded at a high temperature of 190°C for 2 hours in a mixing equipment to obtain a mixed jelly substance;

[0050] Put the mixed jelly substance...

Embodiment 3

[0055] A rollable flexible electrothermal film comprises the following components by weight percentage:

[0056] 45% styrene-based thermoplastic elastomer, 35% graphene and graphite flake composite conductive agent, 4% antioxidant styrenated phenol, 8% mixture of fatty acid derivatives for flow agent, 6% petroleum-based plasticizer, surface Active Agent Anionic Surfactant 2%. Wherein, the composite conductive agent is a composite conductive agent of graphene and graphite sheet, and the mass ratio of graphene:graphite sheet is 1:1.

[0057] Make it as follows:

[0058]According to the above ratio, mix styrene-based thermoplastic elastomer, graphene and graphite sheet composite conductive agent, antioxidant styrenated phenol, flow agent fatty acid derivative, petroleum plasticizer and surfactant anionic surfactant in the mixture Melting and kneading was carried out at a high temperature of 200° C. for 1.5 h in the refining equipment to obtain a mixed gel-like substance.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com