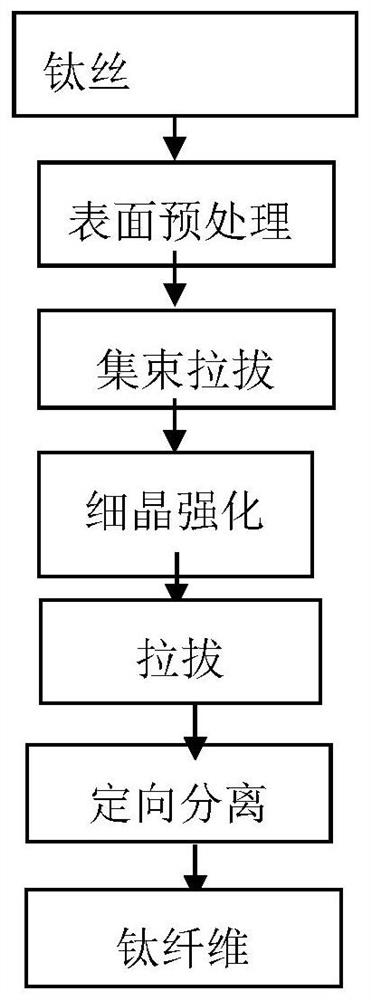

Titanium fiber production process

A production process and technology of titanium fiber, applied in the field of non-ferrous metal processing, can solve the problems of uneven surface finish, high yield of titanium fiber wire, low yield of finished product, etc., and achieve the effect of great application prospect and great market benefit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

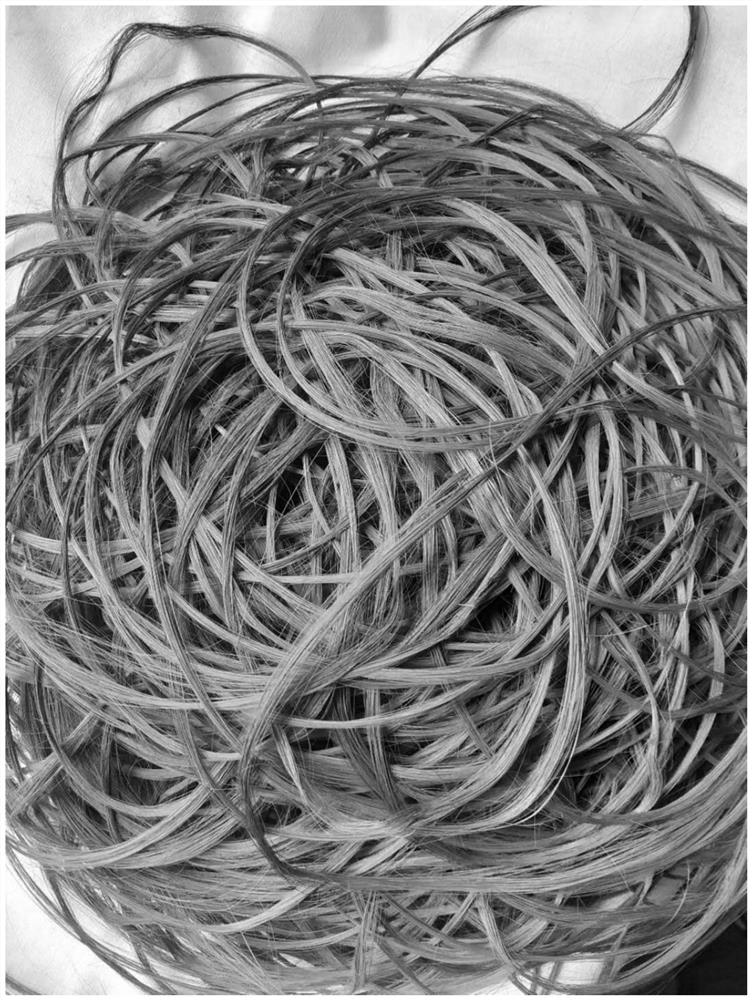

Image

Examples

Embodiment 1

[0062] 1. Select and use 0.5mm titanium wire made of TA1 material as the raw material;

[0063] 2. Copper plating is carried out on the surface of the titanium wire. Use a pretreatment solution with a concentration of 3% nitric acid and hydrofluoric acid mixed acid (nitric acid: hydrofluoric acid = 3:1) to soak and clean the titanium wire for 3 minutes to remove the oxide film on the surface of the titanium wire. . Then use a mixed solution of 50g / L nickel chloride and 10g / L sulfuric acid, use a pure nickel plate on the anode, use a titanium wire as the cathode, and plate nickel for 3 minutes under 6V voltage operation. After pretreatment and pre-nickel plating, use sulfuric acid and copper sulfate solutions of 50g / L copper ions and 1g / L hydrogen ions. The anode is a copper bar, and the titanium wire is used as a cathode. The copper-plated copper layer is covered under the action of a voltage of less than 12V. . Use 680A current and 7m / min speed during copper plating to obta...

Embodiment 2

[0073] 1. Select and use 0.5mm titanium wire made of TA1 material as the raw material;

[0074] 2. Copper plating is carried out on the surface of the titanium wire. Use a pretreatment solution with a concentration of 3% nitric acid and hydrofluoric acid mixed acid (nitric acid: hydrofluoric acid = 3:1) to soak and clean the titanium wire for 3 minutes to remove the oxide film on the surface of the titanium wire. . Then use a mixed solution of 50g / L nickel chloride and 10g / L sulfuric acid, use a pure nickel plate on the anode, use a titanium wire as the cathode, and plate nickel for 3 minutes under 6V voltage operation. After pretreatment and pre-nickel plating, use sulfuric acid and copper sulfate solutions of 50g / L copper ions and 1g / L hydrogen ions. The anode is a copper bar, and the titanium wire is used as a cathode. The copper-plated copper layer is covered under the action of a voltage of less than 12V. . Use 680A current and 7m / min speed during copper plating to obta...

Embodiment 3

[0080] 1. Select and use 0.5mm titanium wire made of TA1 material as the raw material;

[0081] 2. Copper plating is carried out on the surface of the titanium wire. Use a pretreatment solution with a concentration of 3% nitric acid and hydrofluoric acid mixed acid (nitric acid: hydrofluoric acid = 3:1) to soak and clean the titanium wire for 3 minutes to remove the oxide film on the surface of the titanium wire. . Then use a mixed solution of 50g / L nickel chloride and 10g / L sulfuric acid, use a pure nickel plate on the anode, use a titanium wire as the cathode, and plate nickel for 3 minutes under 6V voltage operation. After pretreatment and pre-nickel plating, use sulfuric acid and copper sulfate solutions of 50g / L copper ions and 1g / L hydrogen ions. The anode is a copper bar, and the titanium wire is used as a cathode. The copper-plated copper layer is covered under the action of a voltage of less than 12V. . Use 680A current and 7m / min speed during copper plating to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com