A kind of method for preparing flame retardant polymer polyol, application and polyurethane foam made by the same

A technology of flame-retardant polymers and polyether polyols, applied in the field of polyurethane synthetic materials, can solve the problems of poor flame-retardant performance, high-temperature release of toxic gases containing halogens, etc., achieve low smoke generation, good synergistic effect, and overcome easy migration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

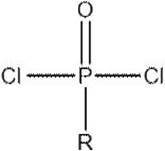

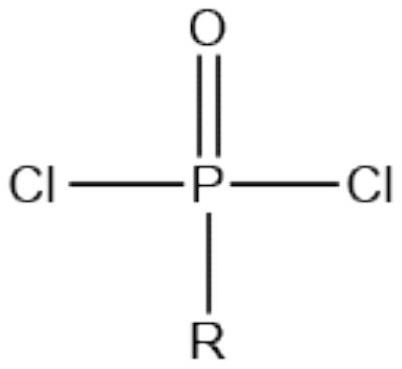

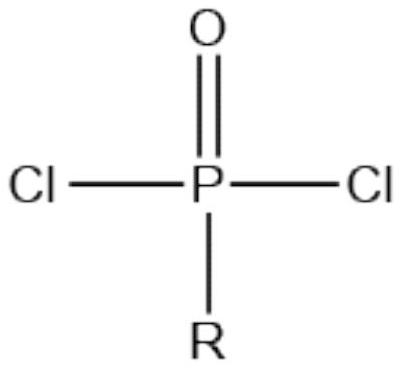

[0031]1) Preparation of phosphoramide: in an inert atmosphere, dissolving phosphoryl dichloride in an organic solvent, adding the organic diamine dissolved in the organic solvent to the above solution dropwise, at a temperature of -30°C to 20°C React at 30-100°C for 1-6h, then heat up to 30-100°C for 0.5-6h; then add acid binding agent, react at 30-100°C for 1-6h, and filter to obtain a colorless and transparent solution.

[0032] 2) Polymerization reaction: add the formaldehyde solution to the phosphoramide solution obtained in step 1), heat it to 60-80 °C, and react for 0.5-2 h; mix the obtained solution with polyether polyol, heat it to 80-100 °C, and react 1 ~3h; under the conditions of pressure of -0.098MPa to -0.08MPa and temperature of 90 to 120° C., vacuuming to remove residual monomers to obtain flame retardant polymer polyol.

[0033] In another embodiment of the present invention, a method for preparing flame retardant polymer polyol with phosphoramide, comprising t...

Embodiment 1

[0066] (1) In a nitrogen atmosphere, 111g of phenylphosphoryl dichloride was dissolved in 223g of tetrahydrofuran, 0.2g of sodium iodide was added, and then 86g of ethylenediamine dissolved in 172g of tetrahydrofuran was added dropwise to the above solution, The reaction was carried out at -5 °C for 3 h, then heated to 50 °C for 3 h; then 121 g of solid sodium carbonate was added, and the solution was filtered at 50 °C for 3 h to obtain a colorless and transparent solution.

[0067] (2) 65g of 37% aqueous formaldehyde solution was added to the phenylphosphoryl diethylenediamine solution obtained in step (1), heated to 80°C, and reacted for 0.5h; the obtained solution was mixed with 350g of polyether polyol 1, heated To 100℃, react for 1h; under the conditions of pressure of -0.098MPa~-0.08MPa and temperature of 100℃, vacuuming to remove residual monomers, a flame retardant with a viscosity of 3176mP·s / 25℃ and a solid content of 30% is obtained Polymer polyol, product phosphoru...

Embodiment 2

[0069] (1) In a nitrogen atmosphere, 80g of methylphosphoryl dichloride was dissolved in 199g of dioxane, 0.36g of sodium iodide was added, and then 101g of propylenediamine dissolved in 252g of dioxane was added dropwise to It was added to the above solution, reacted at 0 °C for 2 h, then heated to 40 °C for 3 h; then added 152 g of solid sodium carbonate, reacted at 40 °C for 3 h, and filtered to obtain a colorless and transparent solution.

[0070] (2) 66g of 37% aqueous formaldehyde solution was added to the methylphosphoryldipropylenediamine solution obtained in step (1), heated to 60° C., and reacted for 2h; the obtained solution was mixed with 350g of polyether polyol 2, and heated to 90℃, reaction for 2h; under the conditions of pressure of -0.098MPa~-0.08MPa and temperature of 110℃, vacuum was used to remove residual monomers, and a flame retardant polymer with viscosity of 2886mP·s / 25℃ and 30% solid content was obtained Polyol, the product has a phosphorus content of 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com