A kind of anti-degradation enhanced proton exchange membrane and its preparation method

A proton exchange membrane and enhanced technology, applied in the field of enhanced proton exchange membrane and its preparation, can solve the problems of poor compatibility between oxides and ionic polymers, increase the overall cost of the proton exchange membrane, and be expensive, and achieve anti-freedom. Radical degradation performance improvement, reducing the effect of membrane electrode aging, and improving the effect of free radical reducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

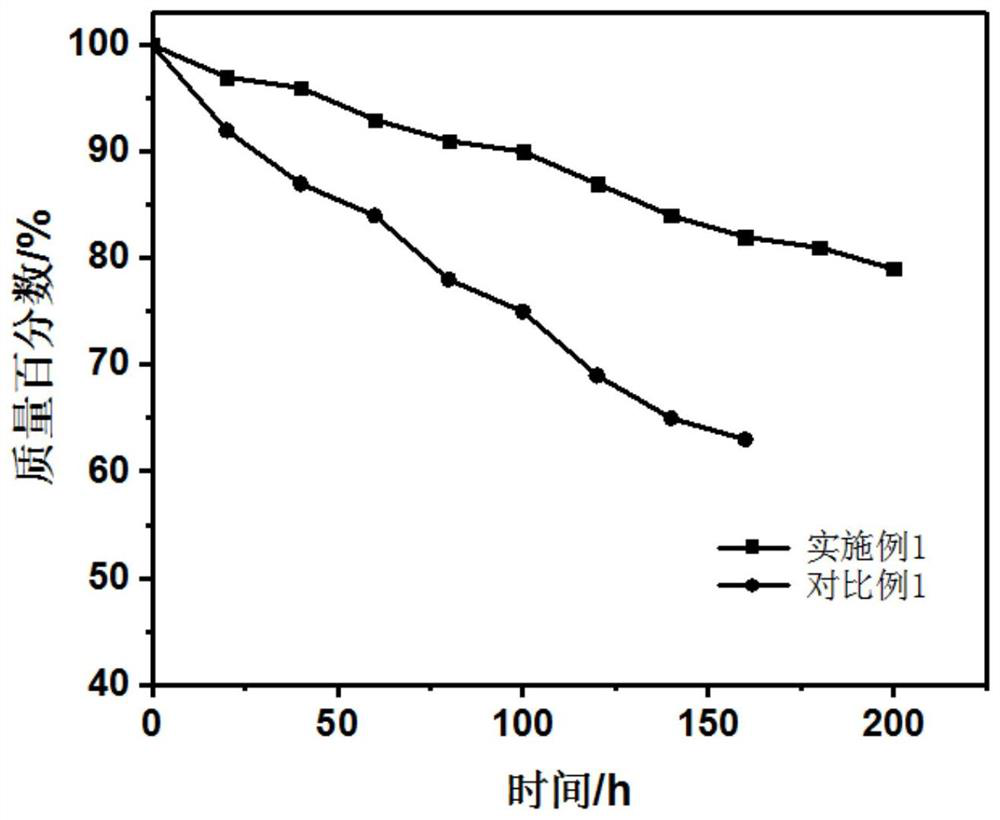

Embodiment 1

[0033] A method for preparing an anti-degradation enhanced proton exchange membrane, comprising the steps of:

[0034] 1) Preparation of casting solution: Disperse 5g of H-type perfluorosulfonic acid resin in isopropanol / water mixture, add 0.05g of vitamin C, place in a hydrothermal reaction kettle and heat to dissolve at 180°C for 6h to obtain free radical quencher compound perfluorosulfonic acid solution, add 30ml DMF to the free radical quencher compound perfluorosulfonic acid solution and carry out vacuum distillation to obtain the casting solution;

[0035] 2) Cleaning and pore activation of the reinforcing material: Soak the ePTFE membrane of the reinforcing material in ethanol to remove organic matter on the surface, and place the treated ePTFE membrane in a free radical quencher compound perfluorosulfonic acid solution for ultrasonic treatment for 1 hour;

[0036] 3) Scrape coating: place the ePTFE film treated in step 2) on a glass plate with a flat surface, then pour...

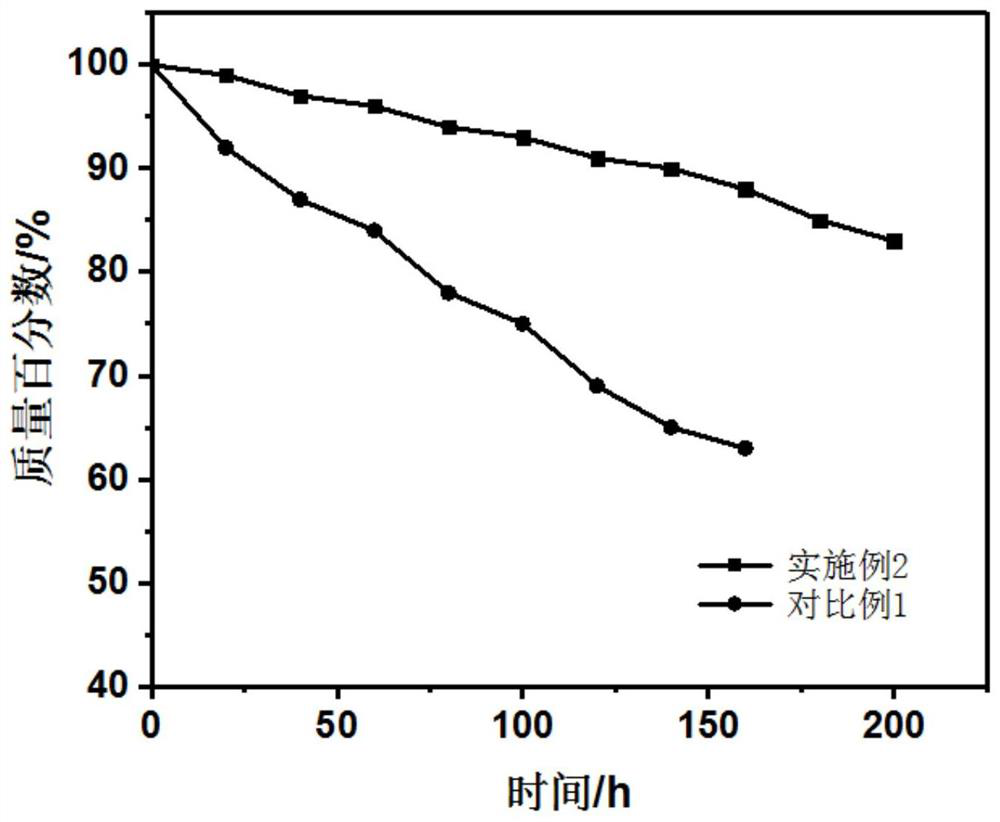

Embodiment 2

[0038] A method for preparing an anti-degradation enhanced proton exchange membrane, comprising the steps of:

[0039] 1) Preparation of casting solution: Disperse 5g of H-type perfluorosulfonic acid resin in isopropanol / water mixture, add 0.05g of vitamin A, place in a hydrothermal reaction kettle and heat at 180°C for 6h to obtain free Radical quencher composite perfluorosulfonic acid solution, add 30ml DMF to the free radical quencher composite perfluorosulfonic acid solution and carry out vacuum distillation to obtain the casting solution;

[0040]2) Cleaning and pore activation of the reinforcing material: Soak the ePTFE membrane of the reinforcing material in ethanol to remove organic matter on the surface, and place the treated ePTFE membrane in a free radical quencher compound perfluorosulfonic acid solution for ultrasonic treatment for 1 hour;

[0041] 3) Scrape coating: place the ePTFE film treated in step 2) on a glass plate with a flat surface, then pour the castin...

Embodiment 3

[0051] A method for preparing an anti-degradation enhanced proton exchange membrane, comprising the steps of:

[0052] 1) Preparation of casting solution: Disperse 5g of SFPEEK in isopropanol / water mixture, add 0.05g of vitamin E, place in a hydrothermal reaction kettle and heat at 180°C for 6h to obtain vitamin E complex SFPEEK solution, Add 30ml DMA to the vitamin E complex SFPEEK solution and carry out vacuum distillation to obtain the casting solution;

[0053] 2) Cleaning and pore activation of the reinforcing material: Soak the PI film of the reinforcing material in ethanol to remove the organic matter on the surface, and place the treated PI film in a vitamin E compound SFPEEK solution for ultrasonic treatment for 1 hour;

[0054] 3) Scrape coating: place the PI film treated in step 2) on a glass plate with a flat surface, then pour the casting solution prepared in step 1) on the surface of the reinforcing material, and use a scraper coating machine with a scrape gap of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com