Method for recovering protein from potato starch processing wastewater

A potato starch and potato protein technology, applied in the field of protein recovery, can solve the problems of low protein recovery rate, achieve the effect of increasing purity, improving extraction rate, and avoiding changes in properties and structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

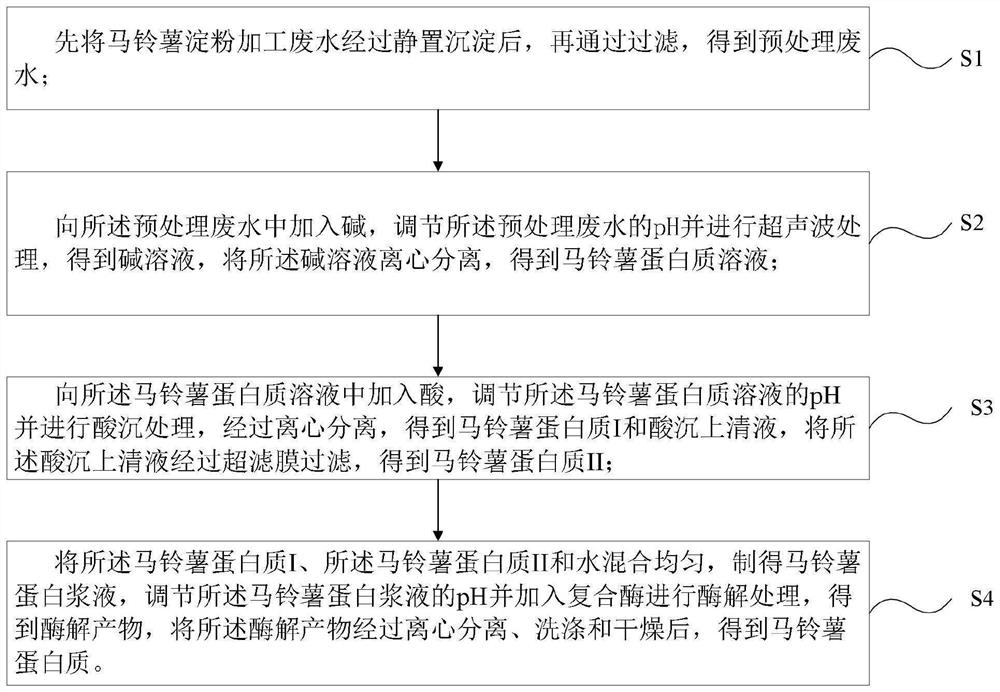

Image

Examples

Embodiment 1

[0057] The present embodiment provides a kind of method that reclaims protein from potato starch processing waste water, comprises the steps:

[0058] 1.1 Potato starch processing wastewater contains a large amount of water-soluble protein, fiber and residual starch, etc., first put the potato starch processing wastewater in the sedimentation tank for 4-6 hours, and then filter it with a centrifugal sieve with a pore size of 50um to obtain pretreatment Wastewater, to remove fiber and other solid non-protein impurities in the potato starch processing wastewater to ensure the purity of the extracted protein;

[0059] 1.2 Add sodium alginate and sodium bicarbonate solution to the pretreated wastewater, and the mass ratio of sodium bicarbonate in the sodium alginate and sodium bicarbonate solution is 1:2, adjust the pH of the pretreated wastewater to 8.5, and Ultrasonic treatment is carried out at 30°C at an ultrasonic power of 50 Hz, and the ultrasonic treatment time is 40 minute...

Embodiment 2

[0064] The present embodiment provides a kind of method that recovers protein from potato starch processing waste water, and its recovery method is identical with embodiment 1, difference is, when preparing potato protein solution, adopt following steps:

[0065] Add sodium alginate and sodium bicarbonate solution to the pretreated wastewater, and the mass ratio of sodium bicarbonate in the sodium alginate and sodium bicarbonate solution is 1:2, adjust the pH of the pretreated wastewater to 9, and Ultrasonic treatment is performed at an ultrasonic power of 60 Hz at ℃, and the ultrasonic treatment time is 30 minutes to obtain a primary treatment solution, which is centrifuged to obtain a primary alkali precipitation and a primary alkaline solution; according to the primary alkali precipitation and water, the ratio of material to liquid is 1g : 2ml mixed evenly to prepare a mixed solution, add sodium alginate and sodium carbonate solution to the mixed solution, and the mass ratio...

Embodiment 3

[0067] The present embodiment provides a kind of method that recovers protein from potato starch processing waste water, and its recovery method is identical with embodiment 1, difference is, when preparing potato protein solution, adopt following steps:

[0068] Add sodium alginate and sodium bicarbonate solution to the pretreated wastewater, and the mass ratio of sodium bicarbonate in the sodium alginate and sodium bicarbonate solution is 1:1, adjust the pH of the pretreated wastewater to 8, and Ultrasonic treatment is performed at an ultrasonic power of 50 Hz at ℃, and the ultrasonic treatment time is 60 minutes to obtain a treatment solution, which is centrifuged to obtain a first alkali precipitation and a first alkali solution; according to the first alkali precipitation and water, the ratio of material to liquid is 1g : 4ml mixed evenly to prepare a mixed solution, add sodium alginate and sodium carbonate solution to the mixed solution, and the mass ratio of sodium carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com