Method for growing yttrium iron garnet crystals by adopting composite fluxing agent

A technology of yttrium iron garnet and flux, which is applied in the direction of melt, single crystal growth, crystal growth, etc. problems, to reduce the difficulty of growth and energy costs, promote the development of industrialization, and promote growth and growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for growing yttrium iron garnet crystals using a composite flux, comprising the following steps:

[0024] (1) Preparation of raw materials: The raw materials used in the experiment are Y with a purity ≥ 99.99% 2 o 3 and Fe 2 o 3 , according to Y 3 Fe 5 o 12 The chemical formula is weighed according to the molar ratio of Y:Fe:O=3:5:12. The weighed raw materials were added into the agate mortar and thoroughly ground for 4 hours to obtain mixed raw materials;

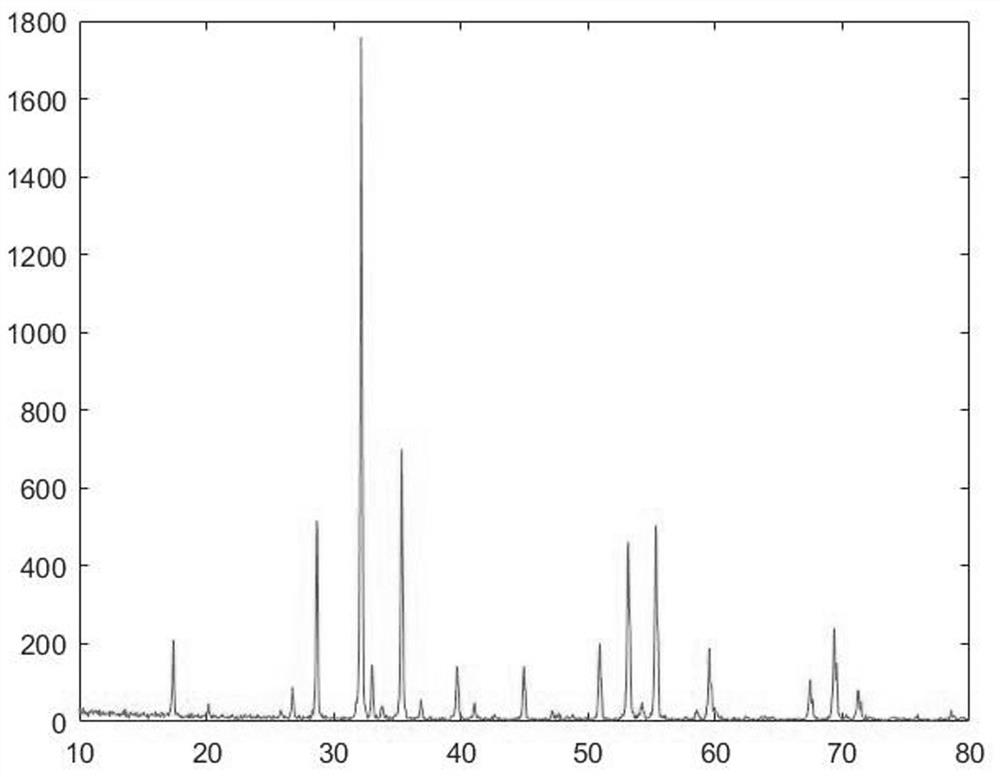

[0025] (2) Preparation of polycrystalline material: put the mixed raw material into a crucible, put it into a muffle furnace, and pre-fire it at 1050 °C for 16 hours to obtain a polycrystalline material of yttrium iron garnet, and crush the polycrystalline material , join Bi 2 o 3 and B 2 o 3 The main composite flux, the flux raw material purity is 99.99%, accounting for 60% of the mixed material, and the mixed material is fully ball milled for 6 hours to obtain a polycrystalline material; figur...

Embodiment 2

[0031] A method for growing yttrium iron garnet crystals using a composite flux, comprising the following steps:

[0032] (1) Preparation of raw materials: The raw materials used in the experiment are Y with a purity ≥ 99.99% 2 o 3 and Fe 2 o 3 , according to Y 3 Fe 5 o 12 The chemical formula is weighed according to the molar ratio of Y:Fe:O=3:5:12. The weighed raw materials were added into an agate mortar and thoroughly ground for 5 hours to obtain mixed raw materials;

[0033] (2) Preparation of polycrystalline material: put the mixed raw material into a crucible, put it into a muffle furnace, and pre-fire it at 1400°C for 10 hours to obtain a polycrystalline material of yttrium iron garnet, which is crushed. Join Bi 2 o 3 and B 2 o 3 The main composite flux, the flux raw material purity is 99.99%, accounting for 50% of the mixed material, and the mixed material is fully ball milled for 6 hours to obtain a polycrystalline material;

[0034] (3) Treatment of seed...

Embodiment 3

[0039] A method for growing yttrium iron garnet crystals using a composite flux, comprising the following steps:

[0040] (1) Preparation of raw materials: The raw materials used in the experiment are Y with a purity ≥ 99.99% 2 o 3 and Fe 2 o 3 , according to Y 3 Fe 5 o 12 The chemical formula is weighed according to the molar ratio of Y:Fe:O=3:5:12. The weighed raw materials were added into the agate mortar and thoroughly ground for 4.5 hours to obtain mixed raw materials;

[0041] (2) Preparation of polycrystalline material: put the mixed raw material into a crucible, put it into a muffle furnace, and pre-fire it at 1250°C for 12 hours to obtain a polycrystalline material of yttrium-iron garnet, and pulverize the polycrystalline material. Join Bi 2 o 3 and B 2 o 3 The main composite flux, the flux raw material purity is 99.99%, accounting for 60% of the mixed material, and the mixed material is fully ball milled for 6 hours to obtain a polycrystalline material;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com