Surface polishing method for 3D printing titanium alloy complex part

A 3D printing and surface polishing technology, applied in the direction of additive processing, etc., can solve the problem of insufficient anodic oxidation, and achieve the effects of industrialization and commercial promotion, simple method and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

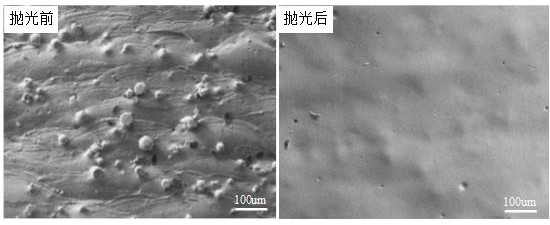

[0018] The surface polishing method of a kind of 3D printing titanium alloy complex part of the present invention, its preferred specific implementation mode is: adopt the formamide and potassium chloride that concentration is respectively 750ml / L, 10g / L as electrolyte, and deionized Mix the water together and stir for 20 minutes to form a mixed electrolyte; add 50nm particle size and 20g / L alumina abrasive grains to the mixed electrolyte, stir well and use it as a polishing liquid; add 10g / L abrasive grains to the polishing liquid Dodecyltrimethylammonium chloride active agent makes the alumina abrasive grains in the polishing liquid positively charged; the 3D printed titanium alloy specimen is immersed in a stainless steel tank filled with polishing liquid, and the 3D printed titanium alloy specimen is connected to the The anode and the stainless steel tank are connected to the cathode; a pulsed DC power supply is applied between the cathode and the anode to perform electroly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com