Method for ultrasonic-assisted electrolytic plasma polishing of titanium alloy

An electrolytic plasma and ultrasonic-assisted technology, which is applied in the field of surface treatment of metal materials, can solve the problems of insufficient anodic oxide and achieve the effects of being beneficial to industrialization and commercial promotion, low cost and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

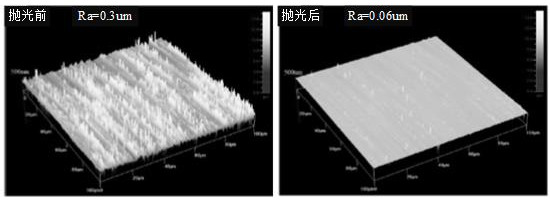

[0017] A method for ultrasonically assisted electrolytic plasma polishing of titanium alloys according to the present invention, its preferred embodiment is: using NaAlO with concentrations of 0.12mol / L, 0.02mol / L, and 0.04mol / L respectively 2 , (NaPO 3 ) 6 and KOH as the electrolyte, and mixed together, after 5 minutes of stirring, the formed mixed electrolyte is used as the polishing solution; the titanium alloy specimen is immersed in the stainless steel tank containing the polishing solution, the titanium alloy specimen is connected to the anode, and the stainless steel tank is connected to the cathode ;Dual pulse power is applied between cathode and anode to perform electrolytic plasma polishing on titanium alloy. The main electrical parameters include: positive polarity voltage 425V, negative polarity voltage 30V, pulse frequency 400Hz, duty cycle 40%; detection of current during polishing Waveform, only in the interpulse stage of the waveform, the ultrasonic device at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com