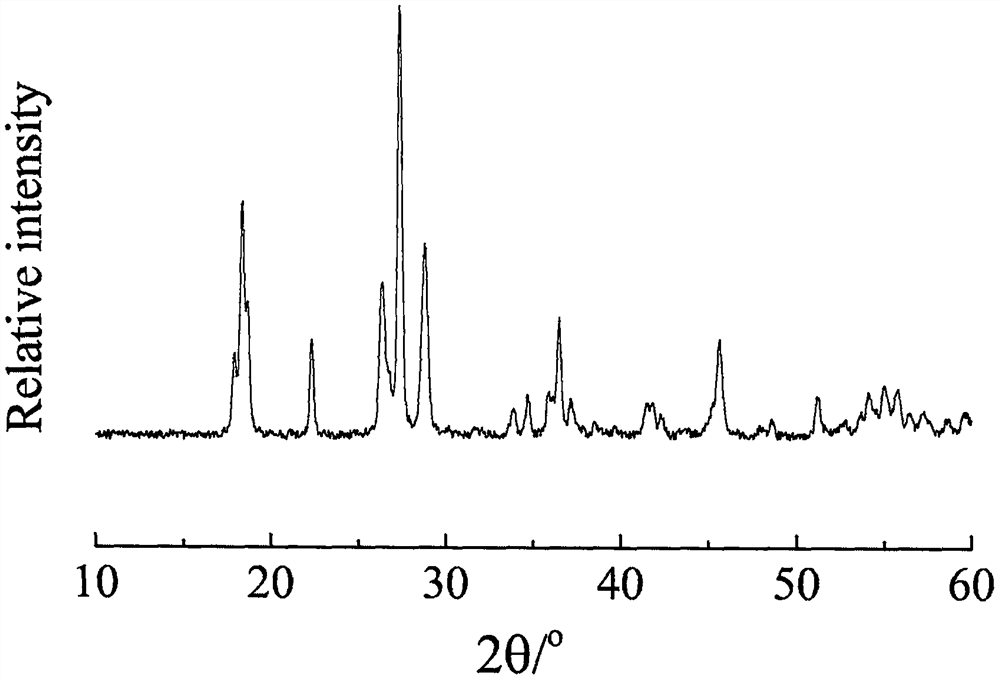

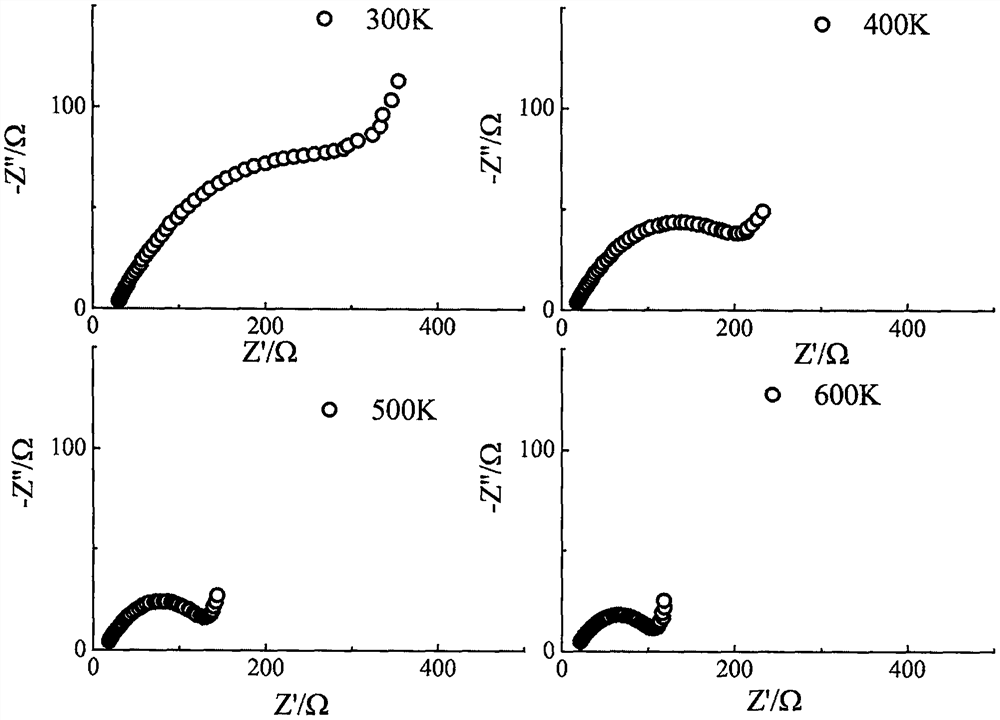

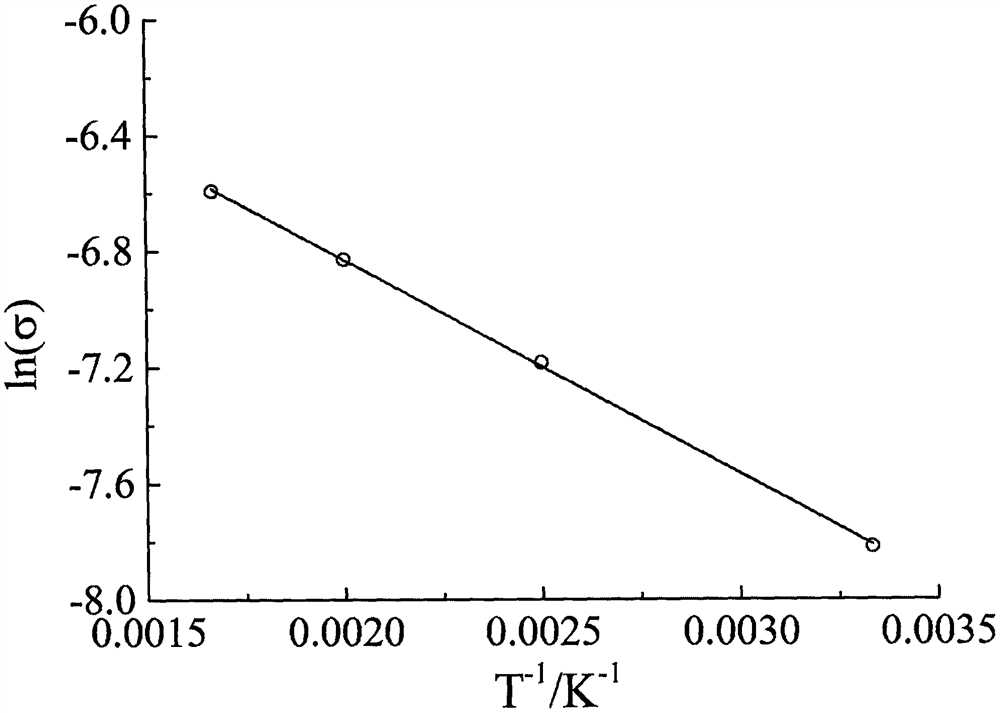

Cl <-> doped epsilon-LiVOPO4 lithium fast ion conductor and liquid phase preparation method thereof

A lithium fast ion and lithium ion technology, applied in chemical instruments and methods, structural parts, inorganic chemistry, etc., can solve the problems of high temperature, high energy consumption, etc., and achieve the improvement of uniformity, uniform reaction raw materials, and favorable conduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015]Example 1: According to LiVO(PO4)0.95Cl0.15Solid LiNO in stoichiometric molar ratio3, NH4H2PO4, LiCl, V2O5And 6 times V2O5The moles of oxalic acid are evenly mixed. While stirring vigorously, add deionized water until all the solid matter is dissolved. Note the mass of the added deionized water, and then continue to add 1.0 times the mass of the recorded deionized water. Ionized water and stir evenly and record this solution as I; mix 3 times the moles of chlorine in solution I of ethylenediaminetetraacetic acid and 2 times the moles of chlorine in solution I of ethylene glycol, mix and add The ammonia water containing the chlorine moles of ammonia in solution I was stirred vigorously while adding deionized water until all the solid matter was dissolved, and again noted the mass of the added deionized water, and then continued to add the deionized water recorded this time 3 times the mass of deionized water and stir it evenly and record this solution as II; add solution II to ...

Embodiment 2

[0016]Example 2: According to LiVO(PO4)0.9Cl0.3Solid LiNO in stoichiometric molar ratio3, NH4H2PO4, LiCl, V2O5And 6 times V2O5The moles of oxalic acid are mixed uniformly. While stirring vigorously, add deionized water until all the solid matter is dissolved. Note the mass of the added deionized water, and then continue to add 1.5 times the mass of the recorded deionized water. Ionized water and stir evenly and record this solution as I; mix 3 times the moles of chlorine in solution I of nitrilotriacetic acid and 2 times the moles of chlorine in solution I of glycerol, mix and add 10 times that of solution I Add the deionized water to the ammonia water with medium chlorine moles of ammonia while vigorously stirring until all the solid matter is dissolved, and again record the mass of the deionized water added, and then continue to add the deionized water recorded this time 5 Double the mass of deionized water and stir it evenly and record this solution as II; add solution II to solu...

Embodiment 3

[0017]Example 3: According to LiVO(PO4)0.93Cl0.21, Where: x = 0.05-0.10, the stoichiometric molar ratio of solid LiNO3, NH4H2PO4, LiCl, V2O5And 6 times V2O5The moles of oxalic acid are mixed uniformly. While vigorously stirring, add deionized water until all the solid matter is dissolved. Note the mass of the added deionized water, and then continue to add 1.2 times the mass of the recorded deionized water. Ionized water and stir evenly and record this solution as I; mix 3 times the moles of chlorine in solution I of nitrilotriacetic acid and 2 times the moles of chlorine in solution I of glycerol, mix and add 10 times that of solution I Add the deionized water to the ammonia water with medium chlorine moles of ammonia while vigorously stirring until all the solid matter is dissolved, and again record the mass of the deionized water added, and then continue to add the deionized water quality recorded this time 4 Double the mass of deionized water and stir it evenly and record this s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com