A kind of preparation method of black zirconia pigment and ceramics

A technology of black zirconia and zirconia biscuit, which is applied in chemical instruments and methods, fibrous fillers, dyeing physical treatment, etc., can solve the problems of mechanical properties reduction of zirconia ceramic materials, and achieve excellent mechanical properties and wide application , the effect of inhibiting volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

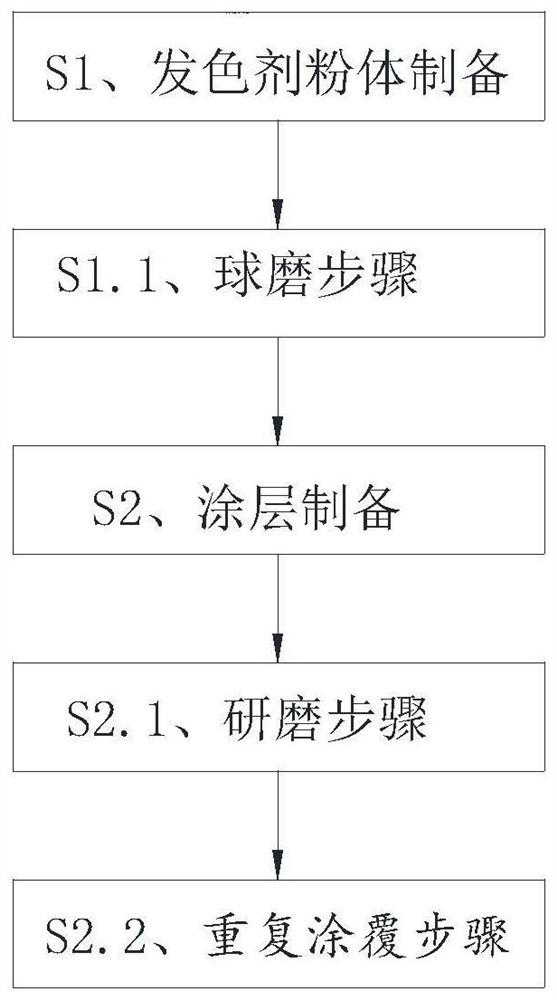

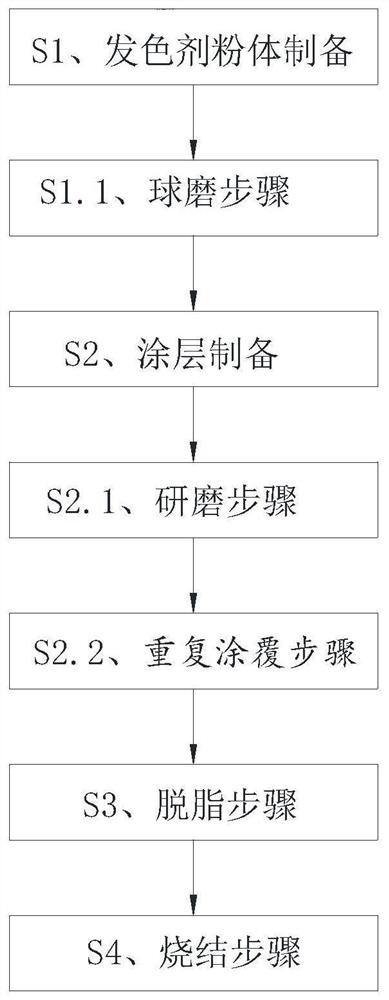

[0032] Such as figure 1 Shown, the preparation method of the black zirconia pigment of the present embodiment comprises the following steps:

[0033] S1. Preparation of chromogenic agent powder: Weigh pure Fe(NO3)3·9H2O and Co(NO3)2·6H2O respectively in evaporating dish with a molar ratio of 2:1, and carefully use a glass rod in a fume hood Heating under stirring makes it melt, and evaporates until completely decomposed to form solid oxides. The solid oxide is transferred to a corundum crucible and pyrolyzed in a muffle furnace. The pyrolysis process is divided into two stages. The heating rate of the first stage is 2-4°C / min, and the heating temperature is 640-660°C. ℃, the holding time is 1-2h; the heating rate of the second stage is 4-6°C / min, the heating temperature is 1265-1285°C, and the holding time is 1-2h. After pyrolysis, the temperature is naturally cooled down to room temperature. The room temperature in this application is 5-35° C., and CFO ferromagnetic powder ...

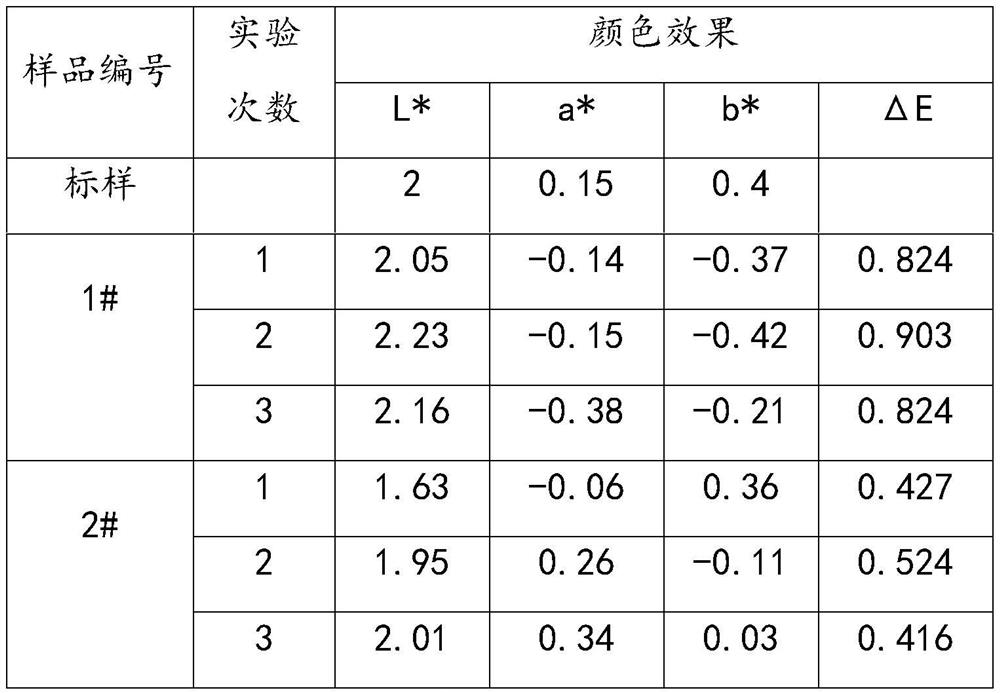

Embodiment 1

[0048] Embodiment 1: The preparation method of the black zirconia color material of this embodiment is the same as the preparation method of the black zirconia color material of the above-mentioned embodiment, and will not be repeated here, and the data of the specific embodiment are as follows:

[0049] S1. Preparation of chromogenic agent powder: The pyrolysis process in this step is divided into two stages. The heating rate of the first stage is 3°C / min, the heating temperature is 650°C, and the holding time is 1h; the heating rate of the second stage is The heating temperature is 5°C / min, the heating temperature is 1275°C, and the holding time is 1.5h.

[0050] S1.1. Ball milling step: in this step, the ball milling time is 4 hours, and the drying heating temperature is 120°C.

[0051] S2. Coating preparation: In this step, 30 parts by mass of the CFO powder, 100 parts by mass of absolute ethanol, and 100 parts by mass of xylene were weighed in this step, and the time for ...

Embodiment 2

[0053] Embodiment 2: the preparation method of the black zirconia pigment of the present embodiment, wherein the data of specific implementation are as follows:

[0054] S1. Preparation of chromogenic agent powder: The pyrolysis process in this step is divided into two stages. The heating rate of the first stage is 2°C / min, the heating temperature is 640°C, and the holding time is 2h; the heating rate of the second stage is The temperature is 4°C / min, the heating temperature is 1265°C, and the holding time is 1h.

[0055] S1.1. Ball milling step: in this step, the ball milling time is 3 hours, and the drying heating temperature is 110°C.

[0056] S2. Coating preparation: In this step, 20 parts by mass of the CFO powder, 100 parts by mass of absolute ethanol, and 100 parts by mass of xylene were weighed in this step, and the time for ultrasonic dispersion and stirring was 10 minutes. The zirconium isopropoxide added was 2 parts by mass, and the solvent added dropwise was 7 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com