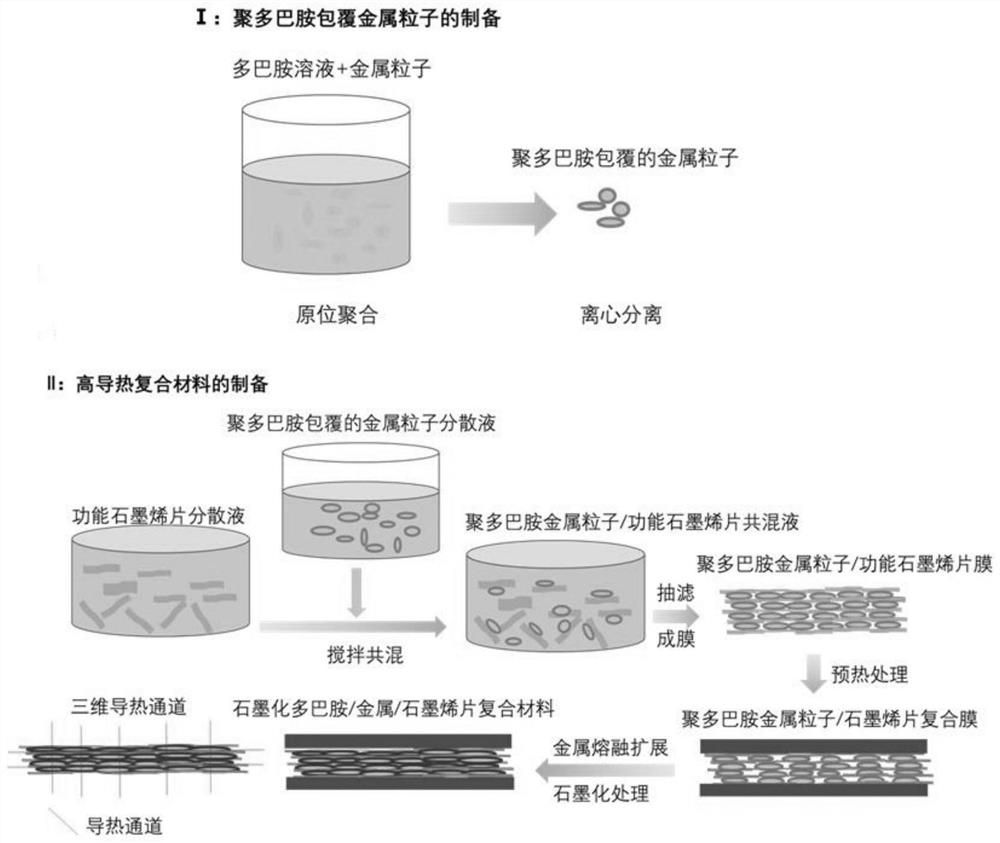

Preparation method of high-thermal-conductivity composite material based on graphitized polydopamine coated metal particles

A polydopamine and metal particle technology, applied in the field of composite materials, can solve problems such as low thermal conductivity, and achieve the effects of high thermal conductivity, simple process and improved thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

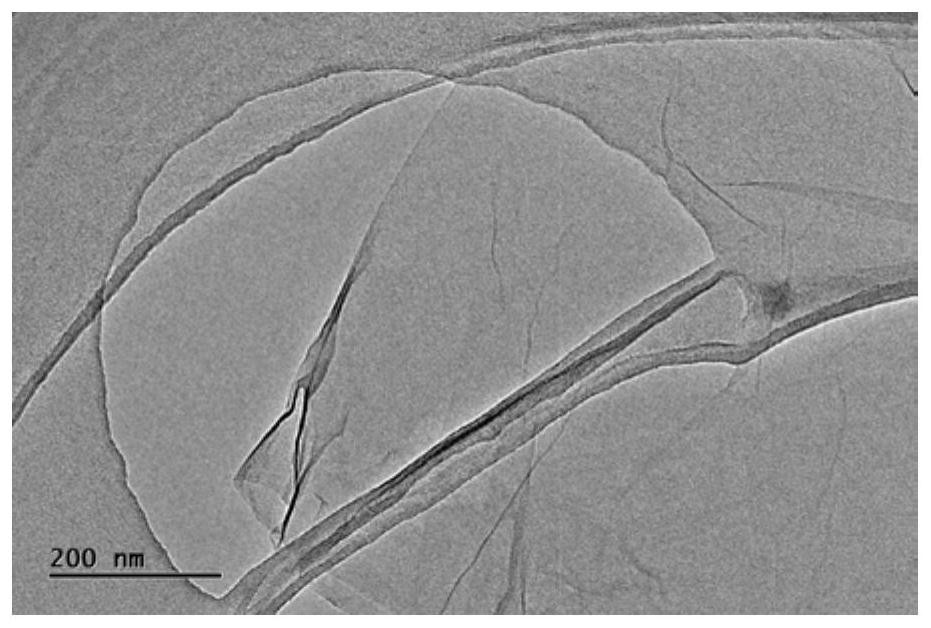

Image

Examples

Embodiment 1

[0022] 1. Weigh 100mg of metal nanoparticles (gold nanorods), disperse them in 10ml of dopamine hydrochloride solution (1mg / ml), stir ultrasonically for 30min, introduce 12.1mg of tris to initiate dopamine polymerization, and react at room temperature Afterwards, the polydopamine-coated metal particles (modified gold nanorods) were obtained by centrifugal separation.

[0023] 2. Weigh 0.5g of functionalized graphene and 0.1g of modified gold nanorods, and disperse them in 50ml of distilled water respectively. Subsequently, the water dispersion of the modified gold nanorods is gradually added to the graphene dispersion under constant stirring, so that the modified gold nanorods are fully combined with the functionalized graphene sheet. The dispersion liquid is vacuum filtered to remove the water solvent to obtain a composite membrane material, and then the composite material is dried supercritically to obtain a graphene / gold nanorod composite material.

[0024]3. Put the obtai...

Embodiment 2

[0026] 1. Weigh 100 mg of metal nanoparticles (gold nanosheets), disperse them in 15 ml of dopamine hydrochloride solution (1 mg / ml), and after ultrasonic stirring for 30 min, introduce 15.5 mg of tris to initiate dopamine polymerization, and react at room temperature Afterwards, the polydopamine-coated metal particles (modified gold nanosheets) were obtained by centrifugal separation.

[0027] 2. Weigh 0.5g of functionalized graphene and 0.1g of modified gold nanosheets, and disperse them in 50ml of distilled water respectively. Subsequently, the water dispersion of the modified gold nanosheets is gradually added to the graphene dispersion under continuous stirring, so that the modified gold nanosheets and the functionalized graphene sheets are fully combined. The dispersion liquid is vacuum filtered to remove the water solvent to obtain a composite membrane material, and then the composite material is dried supercritically to obtain a graphene / modified gold nanosheet composi...

Embodiment 3

[0030] 1. Weigh 100mg of metal nanoparticles (silver nanorods), disperse them in 10ml of dopamine hydrochloride solution (1mg / ml), stir ultrasonically for 30min, introduce 12.1mg of tris to initiate dopamine polymerization, and react at room temperature Afterwards, the polydopamine-coated metal particles (modified silver nanorods) were obtained by centrifugal separation.

[0031] 2. Weigh 0.5g of functionalized graphene and 0.1g of modified silver nanorods, and disperse them in 50ml of distilled water respectively. Subsequently, the water dispersion of the modified silver nanorods is gradually added to the graphene dispersion under continuous stirring, so that the modified silver nanorods and the functionalized graphene sheets are fully combined. The dispersion liquid is vacuum filtered to remove the water solvent to obtain a composite membrane material, and then the composite material is dried supercritically to obtain a graphene / modified silver nanorod composite material.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com