Method for synergistically and efficiently oxidizing sulfur and organic matters in bauxite dissolution slurry

A bauxite and organic matter technology is applied in the field of synergistic high-efficiency bauxite ore dissolution of sulfur and organic matter in slurry, which can solve the problems of reduced equipment requirements and low organic matter removal rate, and achieves the effects of reducing investment costs and shortening reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

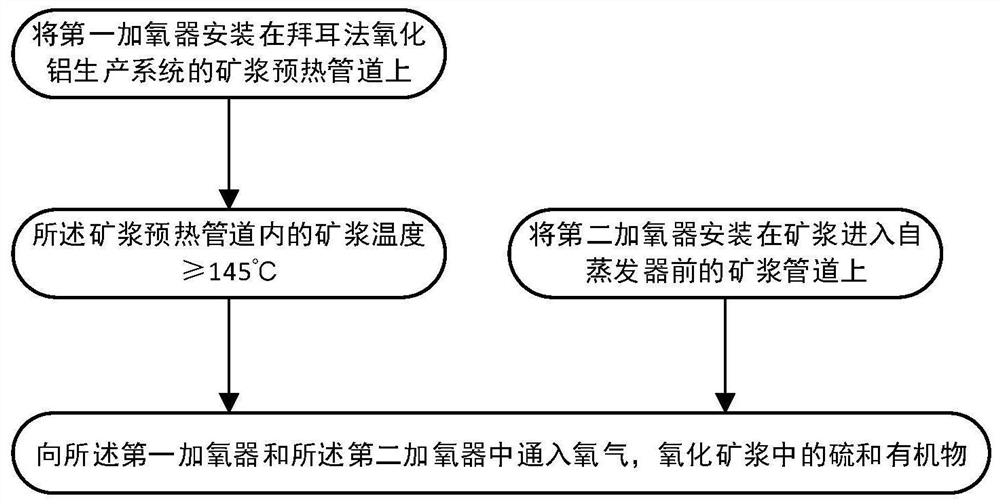

Method used

Image

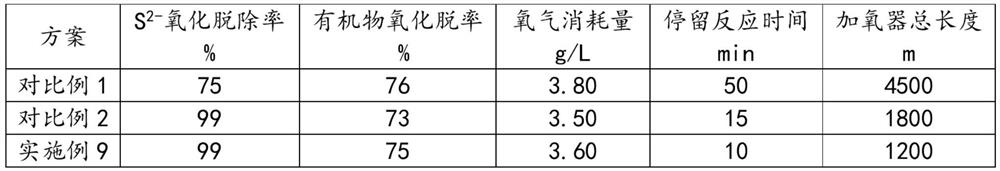

Examples

Embodiment 1

[0055] In the present embodiment bauxite, the alumina content is 56.29%, the silicon dioxide content is 10.01%, the sulfur content is 0.10%, the organic carbon content is 0.10%, and the mother liquor Nk is 243g / L, a k It is 2.90, and the amount of lime added is 10%. The pulp is preheated to 280°C and enters the first oxygenator with an inner diameter of 0.20m. After 50-60 minutes, the pulp of the oxygenator flows through 6 heat preservation tanks in turn, and then enters the second oxygenator with an inner diameter of 0.20m. The residence time is 0.5min; the ore pulp from the second oxygenator flows through the multi-stage self-evaporator to cool down to obtain the dissolution slurry.

[0056] Tested by chemical titration, the S in the dissolution slurry 2- The oxidation removal rate is 98%, S 2 o 3 2- 25% reduction in the content of the organic matter that enters the solution during the stripping process and the oxidation rate reaches 72%. In the above reaction process,...

Embodiment 2

[0058] Aluminum oxide content is 57.31% in the present embodiment bauxite, and silicon dioxide content is 10.61%, and sulfur content is 0.80%, and organic carbon content is 0.40%, and mother liquor Nk is 243g / L, a k It is 2.90, and the amount of lime added is 10%. The pulp is preheated to 145°C and enters the first oxygenator with an inner diameter of 0.27m. After 50 to 60 minutes, the slurry in the tank flows through six heat preservation tanks in turn, and then enters the second oxygenator with an inner diameter of 0.27m. The time is 3.0min; the ore pulp from the two oxygenators flows through the multi-stage self-evaporator to cool down to obtain the dissolution slurry.

[0059] Tested by chemical titration, the S in the dissolution slurry 2- The oxidation removal rate is 98%, S2 o 3 2- The content of the organic matter is reduced by 30%, and the oxidation rate of the organic matter newly entering the solution reaches 71% during the stripping process. In the above react...

Embodiment 3

[0061] Aluminum oxide content is 56.21% in the present embodiment bauxite, and silicon dioxide content is 9.65%, and sulfur content is 0.60%, and organic carbon content is 0.10%, and mother liquor Nk is 240g / L, a k It is 2.90, and the amount of lime added is 10%. The pulp is preheated to 270°C and enters the first oxygenator with an inner diameter of 0.27m. After 50-60 minutes, the pulp of the oxygenator flows through 6 heat preservation tanks in sequence, and then enters the second oxygenator with an inner diameter of 0.27m. The residence time is 1.5min; the ore pulp from the two oxygenators flows through the multi-stage self-evaporator to cool down to obtain the dissolution slurry.

[0062] Tested by chemical titration, the S in the dissolution slurry 2- The oxidation removal rate is 98.5%, S 2 o 3 2- The content of the organic matter that enters the solution in the dissolution process is reduced by 30%, and the oxidation rate of the organic matter newly entering the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com