Patents

Literature

31results about How to "Reduced overall reaction time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing adsorbable oxycellulose through ramie oxidation degumming process

InactiveCN105061606AAdsorptiveImprove adsorption capacityOther chemical processesPaper material treatmentOxidized cellulosePeroxide

The invention provides a method for preparing adsorbable oxycellulose through a ramie oxidation degumming process. The method includes the steps that ramie original hemp serves as a raw material, the original hemp is smashed into short fibers through a smashing machine, and the short fibers are added with deionized water and soaked for pretreatment; a degumming solution is prepared from an oxidizing agent, a stabilizing agent, a fiber expanding agent, a penetrating agent, a chelating agent and water, the ramie original hemp and the degumming solution are mixed, gum in the ramie original hemp is fully removed by means of oxidizability of hyperoxide, and cellulose with active hydroxyl groups is oxidized into oxycellulose containing a great number of formyl groups; the oxycellulose is separated from water and dried to obtain the oxycellulose in the powder state. The method is simple in flow path, environmentally friendly, low in requirement for equipment and beneficial for large-scale production and has good economic and social benefits, the total reaction time is shortened, chemicals and cost are saved, efficiency is greatly improved, reaction conditions are moderate, and additional value of the cellulose is substantially increased.

Owner:DONGHUA UNIV

Production device and production method of liquid sodium dimethyl dithiocarbamate

The invention discloses a production device and a production method of liquid sodium dimethyl dithiocarbamate. The production device comprises a reaction kettle, wherein the upper part of the reaction kettle is respectively communicated with a dimethylamine head tank, a sulfur dioxide head tank and a sodium hydroxide head tank by pipelines; the lower part of the reaction kettle is connected with a reaction kettle dump valve; and the reaction kettle dump valve is sequentially communicated with a filter, a finished product allocation tank and a finished product storage tank sequentially by pipelines. The production method comprises the following steps of: measuring carbon bisulfide, a 30% sodium hydroxide solution and 40% dimethylamine at a mass ratio, placing a dimethylamine solution into the reaction kettle, mixing, supplying a cooling medium to a reaction kettle jacket and an internal cooling coil tube, pressing carbon bisulfide into a synthetic kettle when the temperature of the kettle drops to 10-20 DEG C, then pressing the 30% sodium hydroxide solution into the synthetic kettle, slowly opening a synthetic kettle dump valve, and pressing a material in the reaction kettle into the filter and then into the finished product allocation tank.

Owner:青岛中科荣达新材料有限公司

Method for preparing bleeding stopping oxidized celluloses in ramie oxidation degumming procedures

ActiveCN106478825AChange structureWith hemostatic functionSurgical adhesivesPharmaceutical delivery mechanismOrganic solventColloid

The invention provides a method for preparing bleeding stopping oxidized celluloses in ramie oxidation degumming procedures. The method includes smashing raw ramie to obtain short fibers and soaking the short fibers to sufficiently moisten the short fibers and allow the short fibers to sufficiently swell; mixing the pretreated raw ramie short fibers and degumming solution with one another to obtain mixtures, heating the mixtures, then preserving heat, sufficiently removing colloid in the raw ramie by the aid of oxidability of specific oxidizing agents and simultaneously oxidizing celluloses with active hydroxyl to obtain oxidized celluloses with a large quantity of carboxyl; soaking oxidized and treated fibers by the aid of organic solvent aqueous solution and removing the unreacted oxidizing agents; separating the oxidized celluloses from water and carrying out drying treatment on the oxidized celluloses to ultimately obtain the powdery bleeding stopping oxidized celluloses. The method has the advantages that processes are simple, the original two working procedures are combined into a single working procedure, accordingly, the total reaction time can be shortened, medicines and the cost can be saved, and the efficiency can be greatly improved; the bleeding stopping oxidized celluloses which are products prepared by the aid of the method are high in bleeding stopping speed and bleeding stopping efficiency and can be widely applied to quickly stopping bleeding under conditions of war wound, trauma and the like, and stable effects can be realized.

Owner:DONGHUA UNIV

Method for preparing heavy metal ion adsorbents in ramie oxidization degumming procedures

InactiveCN106475065APromote regenerationIncrease added valueOther chemical processesWater contaminantsAbsorption capacitySorbent

The invention provides a method for preparing heavy metal ion adsorbents in ramie oxidization degumming procedures. The method includes smashing raw ramie to obtain short fibers, adding the short fibers into deionized water and soaking the short fibers; mixing the raw ramie and degumming solution with each other to obtain mixtures, heating the mixtures, sufficiently removing colloid in the raw ramie by the aid of oxidizing agents, and simultaneously oxidizing celluloses with active hydroxyl into oxidized celluloses with aldehyde; soaking reacted fibers in organic solvent aqueous solution and removing the unreacted oxidizing agents; separating the oxidized celluloses from water and drying the oxidized celluloses to obtain powdery oxidized cellulose adsorbents; preparing heavy metal solution, adding the oxidized cellulose absorbents into the heavy metal solution, carrying out vibration adsorption at the room temperature and measuring heavy metal ion absorption capacity numerical values. The method has the advantages that the adsorbents prepared by the aid of the method are low in residual gum content, moderate in crystallinity degree and polymerization degree and high in aldehyde content, and excellent heavy metal ion adsorption effects can be realized; working procedures are simplified, the total reaction time can be shortened, medicines and the cost can be saved, and the efficiency can be greatly improved.

Owner:DONGHUA UNIV

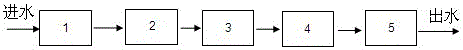

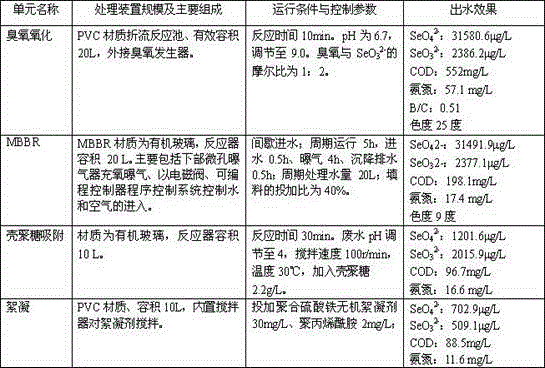

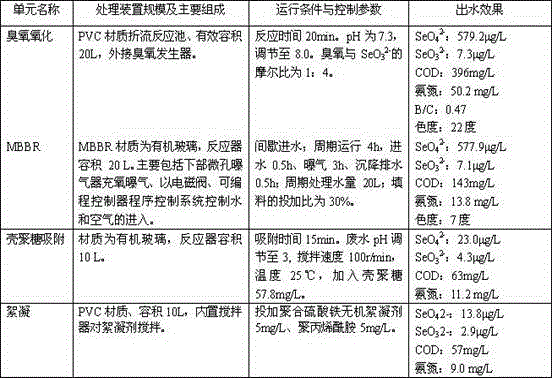

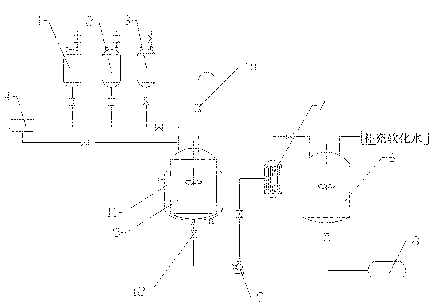

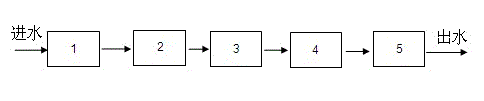

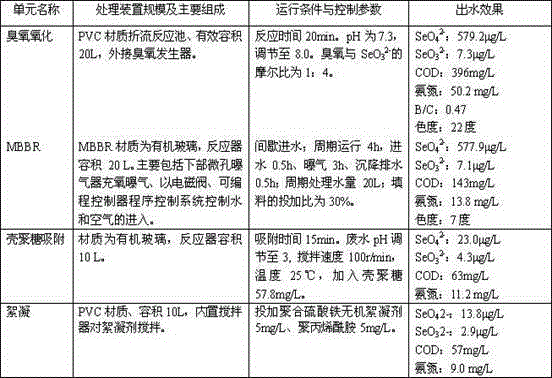

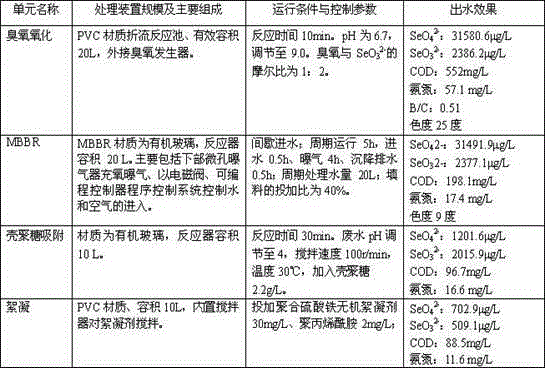

Treatment method of selenium-containing wastewater

ActiveCN104556543AIncreased toxicityLow toxicityWater contaminantsMultistage water/sewage treatmentFlocculationWastewater

The invention discloses a treatment method of selenium-containing wastewater. The treatment method comprises the following steps: regulating the pH of the selenium-containing wastewater to 8-10, and carrying out ozonation in an ozone reactor to oxidize a selenite ion (SeO3<2->) into a selenate radical ion (SeO4<2->); carrying out aerobic biological treatment, regulating the pH to 3-5, and carrying out chitosan (CTS) adsorption; finally feeding the product into a flocculation sedimentation tank, adding a flocculant, stirring, and carrying out solid-liquid separation, so as to obtain wastewater without selenium. The treatment method has the beneficial effects that the removal rate of the selenium in the wastewater is high, the application range is wide, and the operation is easy and convenient.

Owner:CHINA PETROLEUM & CHEM CORP +1

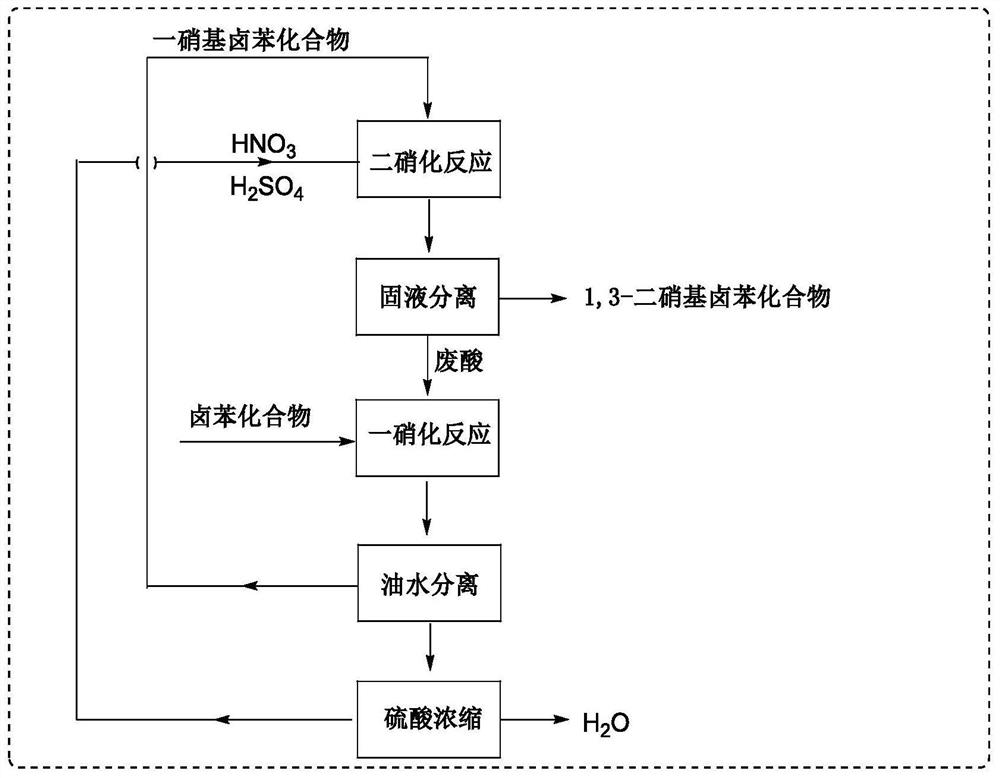

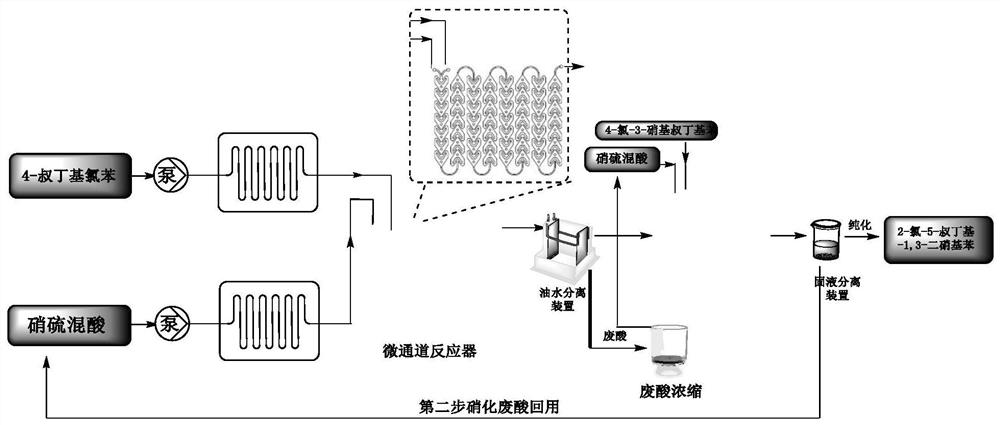

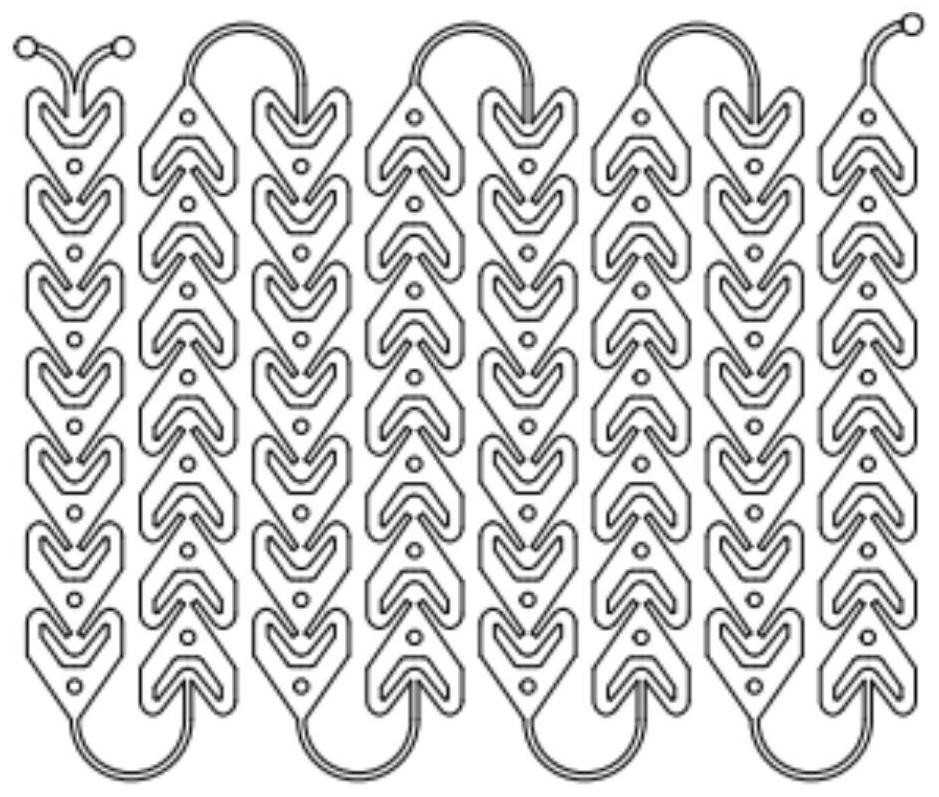

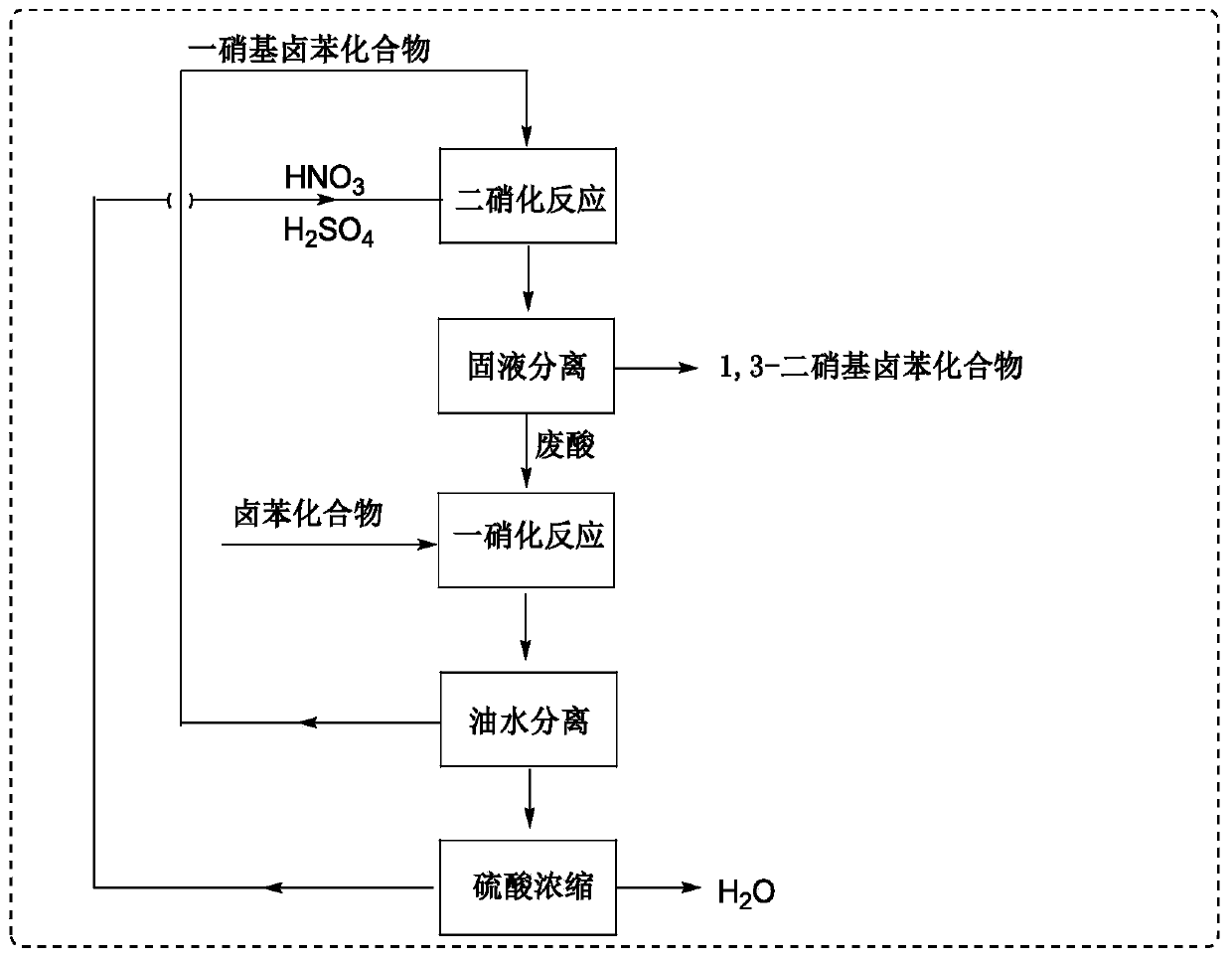

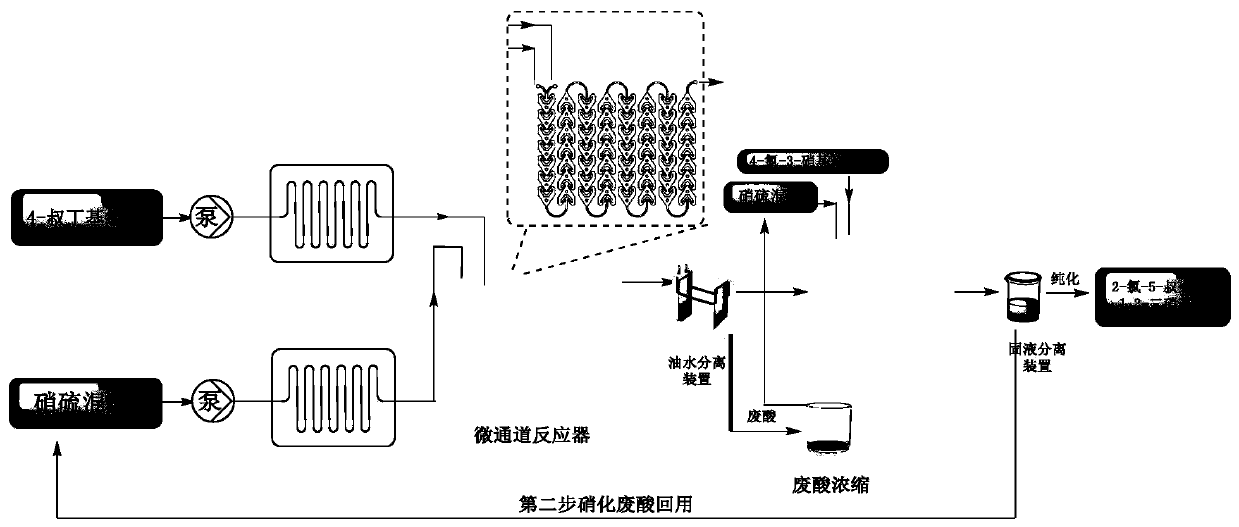

Method for synthesizing 1,3-dinitrohalobenzene compound

ActiveCN109970566ADropping time is longLong reaction heatSequential/parallel process reactionsChemical/physical/physico-chemical microreactorsMicroreactorNitration

The invention provides a method for synthesizing a 1,3-dinitrohalobenzene compound. The method comprises the following steps that A) a halogenated benzene compoundand mixed acid of nitric acid and sulfuric acid are subjected to a first nitrification reaction in a first-stage continuous flow microreactor, and oil-water separation is conducted to obtain a mononitrohalobenzene compound and first waste acid; B) the mononitrohalobenzene compound is drained into a second-stage continuous flow microreactor, a second nitrification reaction is conducted with the mixed acid of the nitric acid and the sulfuric acid, a generated nitration mixture is quenched at the outlet of the second-stage continuous flow microreactor, and filtering is conducted to obtain the 1,3-dinitrohalobenzene compound and second waste acid; C) the second waste acid is recycled to the first-stage continuous flow microreactor, a third nitration reaction with the halobenzene compound is carried out, the oil-water separation is conducted to obtain the mononitrohalobenzene compound and third waste acid, and steps B) and C) are repeated; the halobenzene compound has a structure shown in the formula I. The reaction time is short, the waste acid is less, and continuous production is achieved.

Owner:SHANDONG HIMILE CHEM TECH

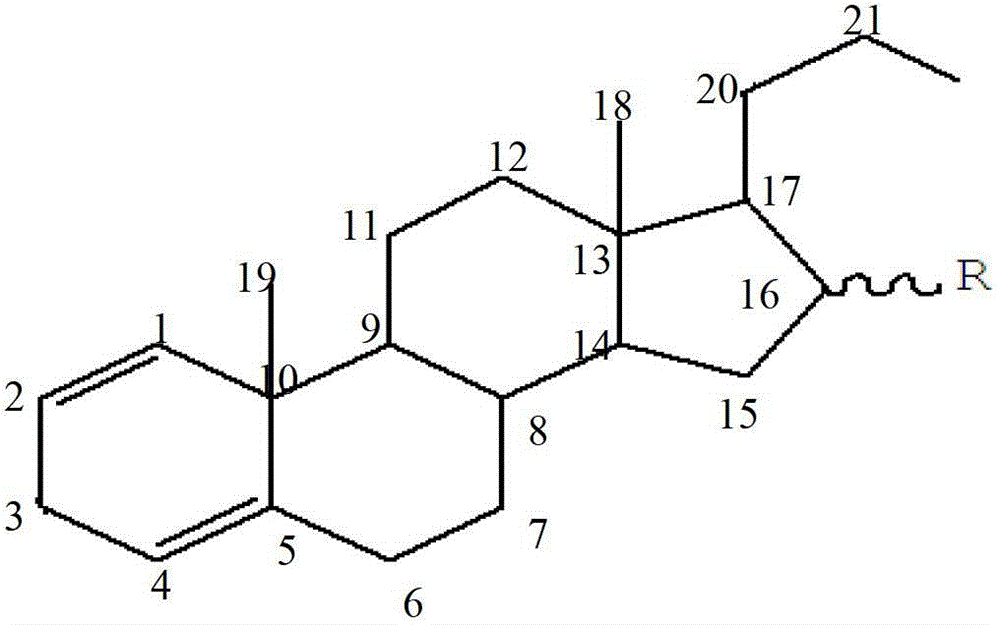

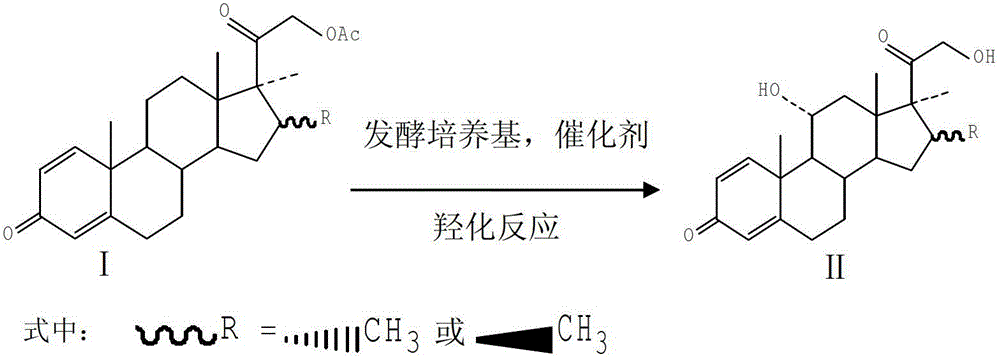

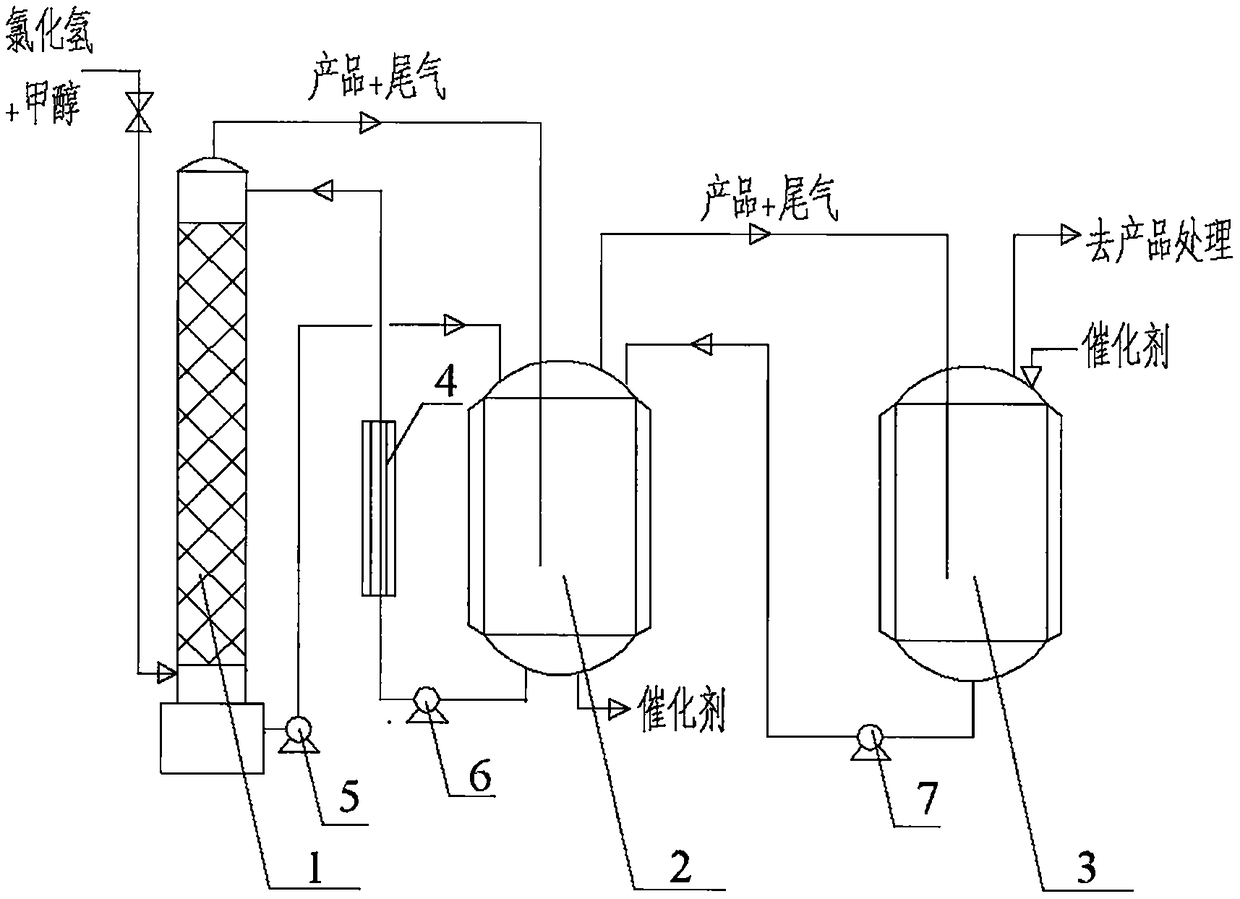

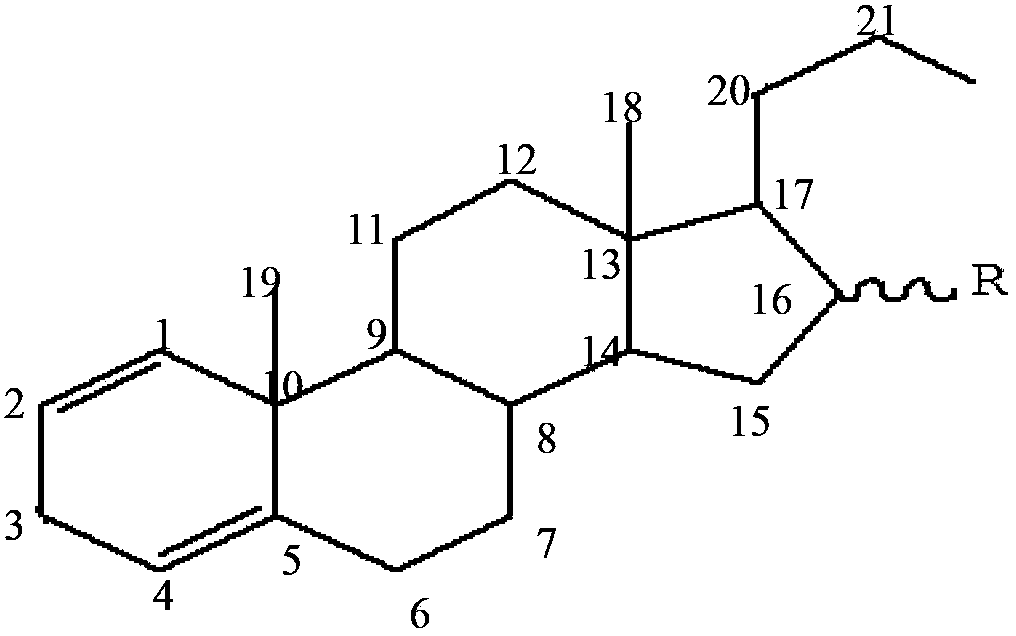

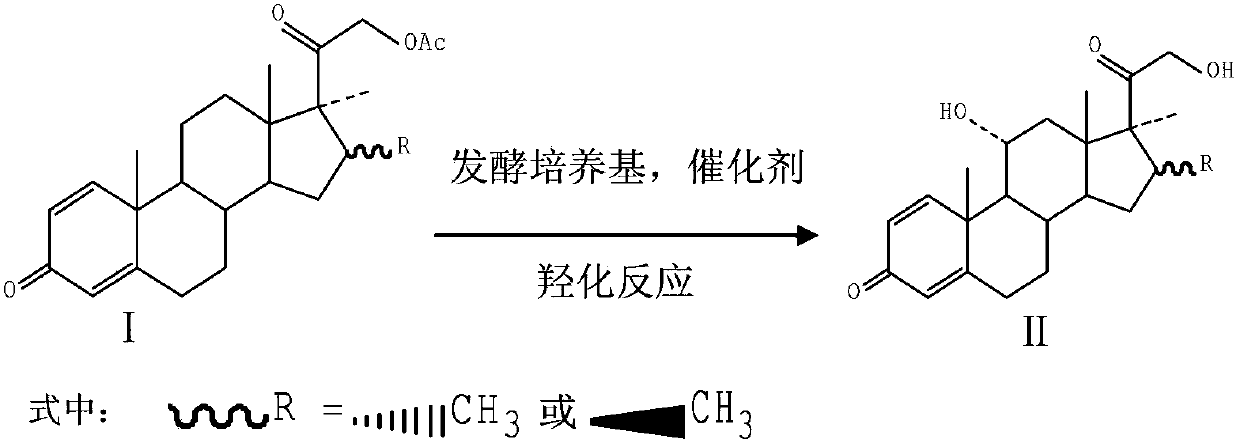

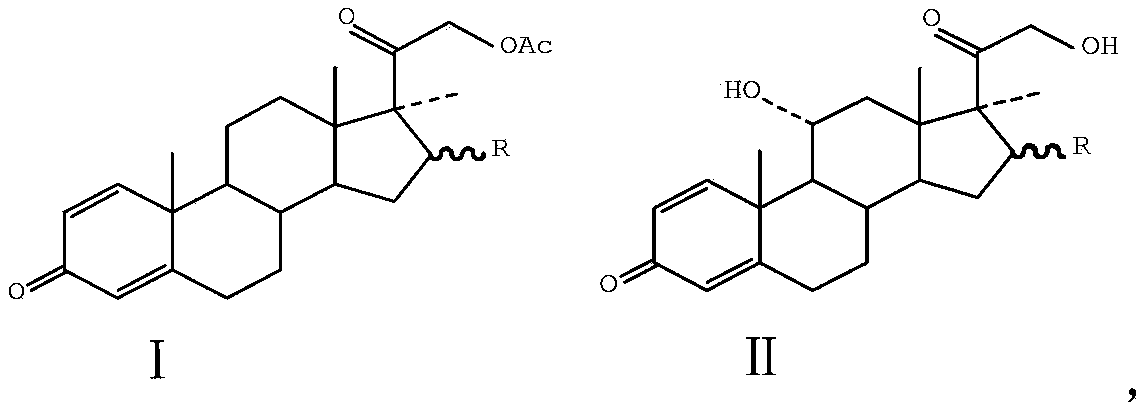

11-alpha hydroxylation reaction preparation method of steride hormone substance important intermediate

ActiveCN103146793ALow costIncrease costMicroorganism based processesFermentationHormones regulationReaction speed

The invention relates to a 11-alpha hydroxylation reaction preparation method of a steride hormone substance important intermediate. The reaction preparation method comprises the following steps of: inputting a steride substrate I into a fermentation medium containing mold seeds to ferment, carrying out the hydroxylation reaction under the effect of the mold and a catalyst, and modifying 11 sites and 21 sites of the steride substrate I to obtain the steride hormone substance important intermediate II with 11-alpha-hydroxy and 21 hydroxy. According to the reaction preparation method, a borate catalyst is used, so that the reaction speed is improved, the reaction time is saved, the consumption of air in a fermentation process is reduced, and simultaneously, the conversion rate is improved by about 5%; and the synthetic medium is used for replacing a natural medium, so that the cost is reduced, and the section pressure of subsequent separation is relieved.

Owner:GUANGXI WANDE PHARMA

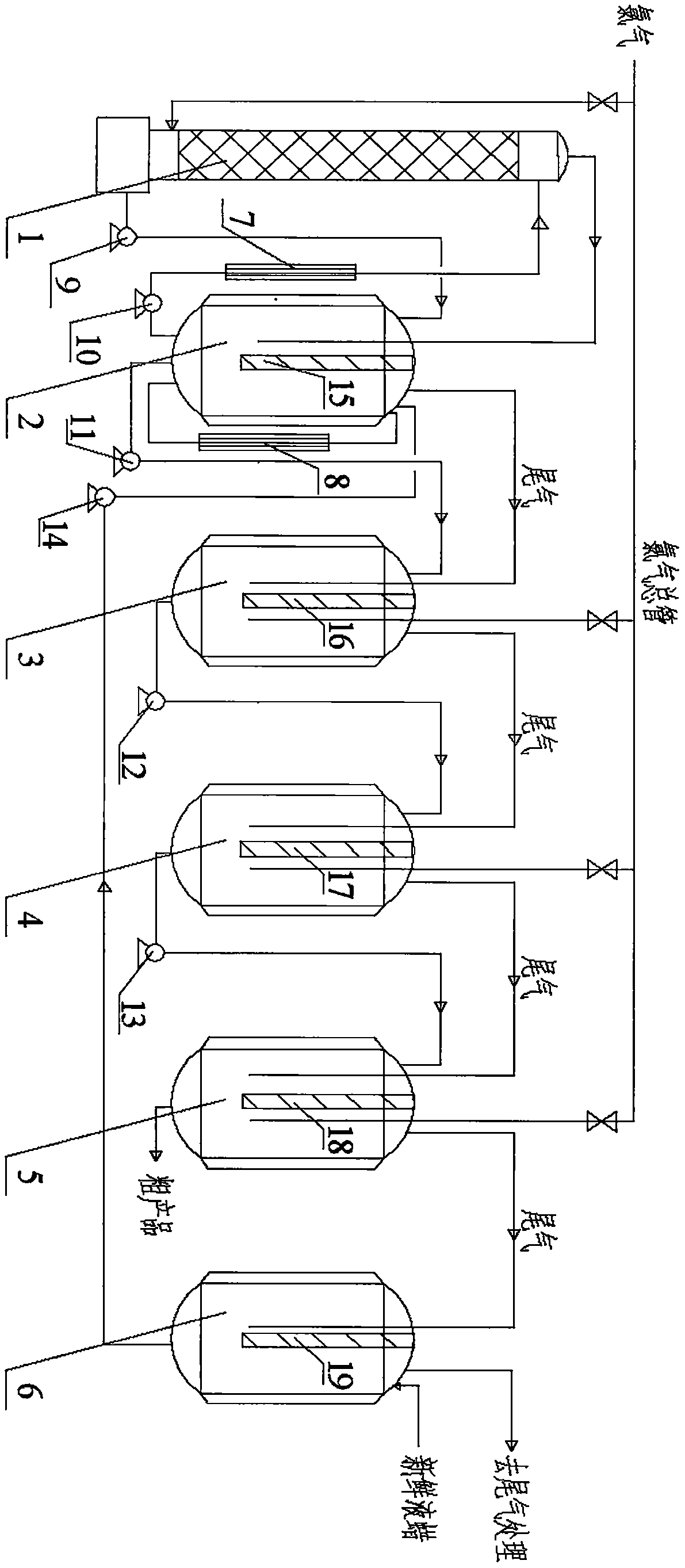

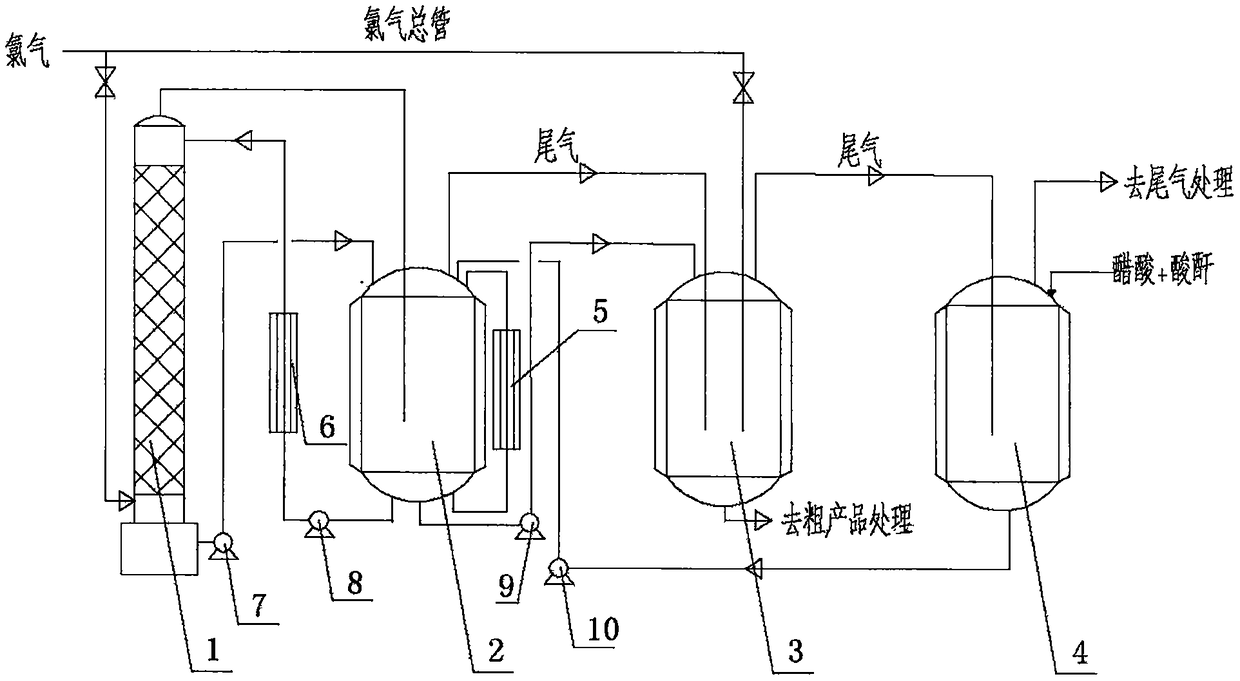

Continuous chloride production device

InactiveCN109364868AAchieve serializationReduce intensityProcess control/regulationChemical/physical/physico-chemical stationary reactorsGas phaseChloride

The invention discloses continuous chloride production device for continuous production of chlorinated paraffin, chloroacetic acid, methyl chloride and the like. The device comprises all or several ofan absorption tower, a reaction kettle, a refining kettle, an absorption tank, a heat exchanger and an exhaust gas treatment device, wherein the absorption tower is connected with the reaction kettleand the heat exchanger is arranged therebetween; and the reaction kettle is connected the refining kettle and the absorption tank in sequence. Under a stable production state, a gas phase continuously enters the absorption tower and the refining kettle, respectively; a liquid phase is continuously added through the absorption kettle, pre-reacted with the unreacted gas phase, introduced into the reaction kettle, and sequentially introduced into the refining kettle after circularly absorbing the gas phase in the reaction kettle and the absorption tower, and the formed liquid crude product or deactivated catalyst is continuously discharged; the gas formed in the absorption tower sequentially collects the gas in the reaction kettle and the refining tank and then enters the absorption kettle,and after pre-reaction, exhaust gas is removed or collected by a gas product collection device. The device realizes the continuous production of chlorides, improves production efficiency and product yield, and enhances the control performance of reaction.

Owner:申素英

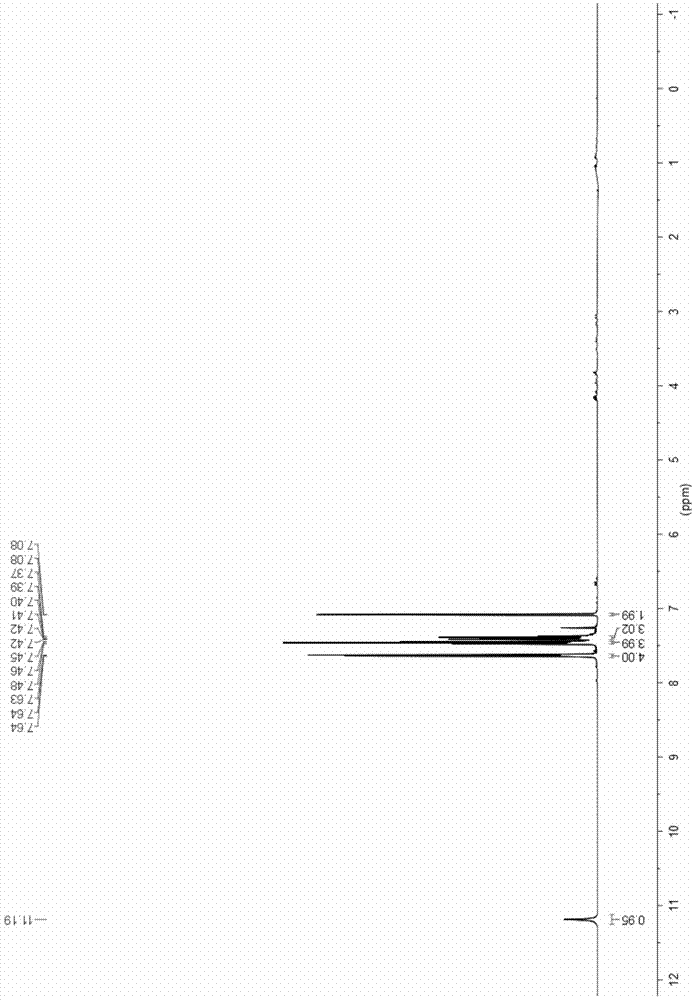

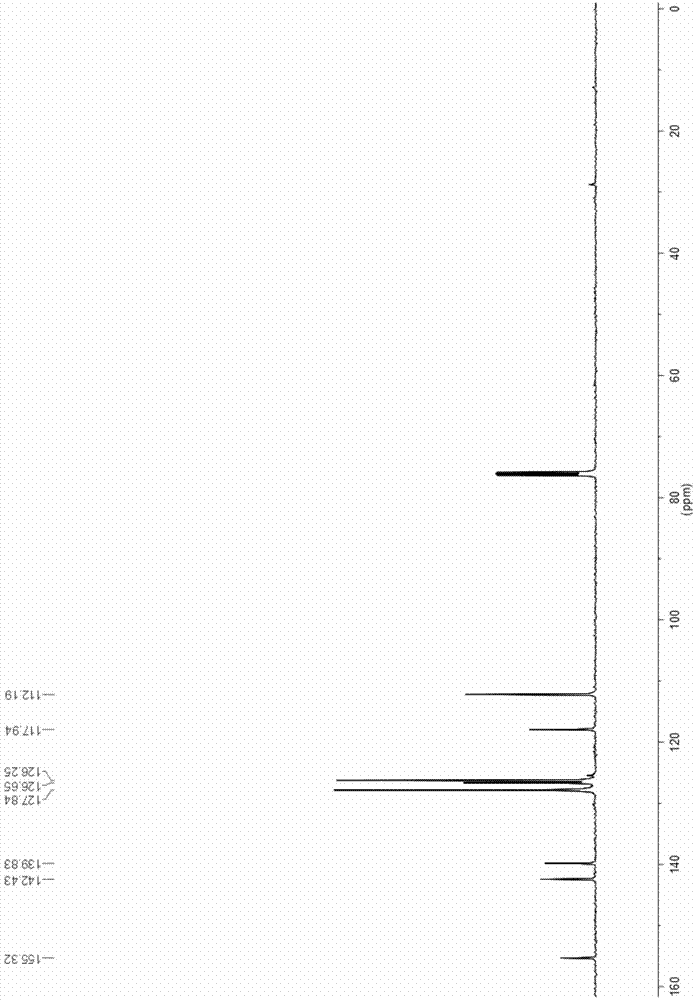

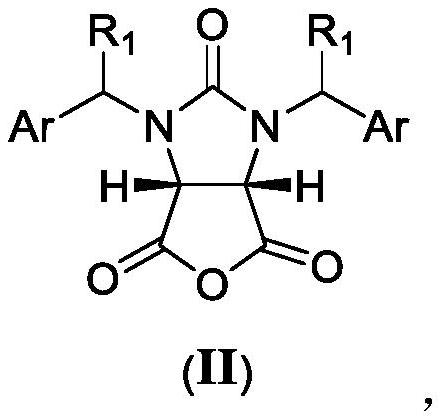

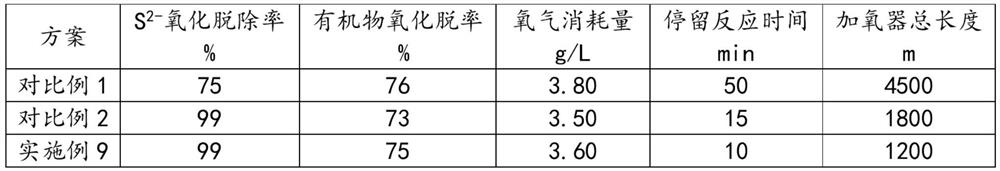

Method for synthesizing persantine intermediate 2,4,6,8-tetrahydroxy pyrimido[5,4-d] pyrimidine

ActiveCN101899046AFewer filtering stepsShorten the timeOrganic chemistryUrea derivativesReaction temperature

The invention relates to a method for synthesizing a persantine intermediate 2,4,6,8-tetrahydroxy pyrimido[5,4-d] pyrimidine, comprising the following steps of: (1) adding nitro orotic acid in an alkali liquid, then hydrogenating with Ni / H2, and filtering to obtain an amino orotic acid solution which is directly used for next reaction without separation; (2) adjusting pH of the amino orotic acid solution with concentrated hydrochloric acid to 3, adding sodium cyanate for temperature control reaction to obtain the urea derivatives of the amino orotic acid; then dropping a 30% sodium hydroxide solution to adjust pH to 13, heating for cyclization, dropping a 50-60% sulfuric acid solution to adjust pH to 3; (3) cooling to room temperature, filtering, washing to neutrality and drying to obtain the product. The intermediate of step (1) is not needed to separate, thereby saving a lot of time and labor, reducing about 50% of total reaction time with mild reaction condition and maximum reaction temperature reduced to 95 DEG C so that the device is less required and more durable.

Owner:ZHEJIANG HUABANG MEDICAL & CHEM

11-alpha hydroxylation reaction preparation method of steride hormone substance important intermediate

ActiveCN103146793BThe ingredients are clear and clearRelieve pressureMicroorganism based processesFermentationHormones regulationReaction speed

The invention relates to a 11-alpha hydroxylation reaction preparation method of a steride hormone substance important intermediate. The reaction preparation method comprises the following steps of: inputting a steride substrate I into a fermentation medium containing mold seeds to ferment, carrying out the hydroxylation reaction under the effect of the mold and a catalyst, and modifying 11 sites and 21 sites of the steride substrate I to obtain the steride hormone substance important intermediate II with 11-alpha-hydroxy and 21 hydroxy. According to the reaction preparation method, a borate catalyst is used, so that the reaction speed is improved, the reaction time is saved, the consumption of air in a fermentation process is reduced, and simultaneously, the conversion rate is improved by about 5%; and the synthetic medium is used for replacing a natural medium, so that the cost is reduced, and the section pressure of subsequent separation is relieved.

Owner:GUANGXI WANDE PHARMA

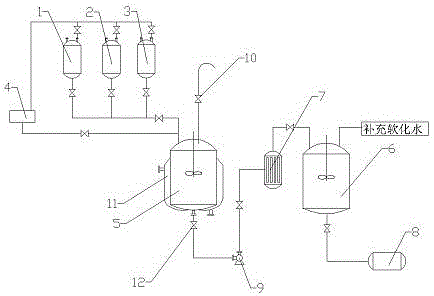

A kind of production device and production method of liquid forma sodium

ActiveCN103214405BReduced overall reaction timeReduce lossOrganic chemistryCooling coilDithiocarbamate

The invention discloses a production device and a production method of liquid sodium dimethyl dithiocarbamate. The production device comprises a reaction kettle, wherein the upper part of the reaction kettle is respectively communicated with a dimethylamine head tank, a sulfur dioxide head tank and a sodium hydroxide head tank by pipelines; the lower part of the reaction kettle is connected with a reaction kettle dump valve; and the reaction kettle dump valve is sequentially communicated with a filter, a finished product allocation tank and a finished product storage tank sequentially by pipelines. The production method comprises the following steps of: measuring carbon bisulfide, a 30% sodium hydroxide solution and 40% dimethylamine at a mass ratio, placing a dimethylamine solution into the reaction kettle, mixing, supplying a cooling medium to a reaction kettle jacket and an internal cooling coil tube, pressing carbon bisulfide into a synthetic kettle when the temperature of the kettle drops to 10-20 DEG C, then pressing the 30% sodium hydroxide solution into the synthetic kettle, slowly opening a synthetic kettle dump valve, and pressing a material in the reaction kettle into the filter and then into the finished product allocation tank.

Owner:青岛中科荣达新材料有限公司

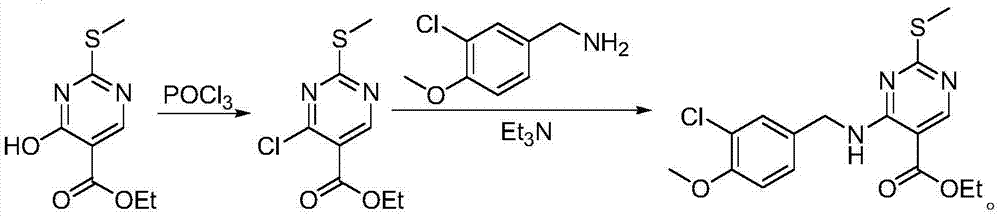

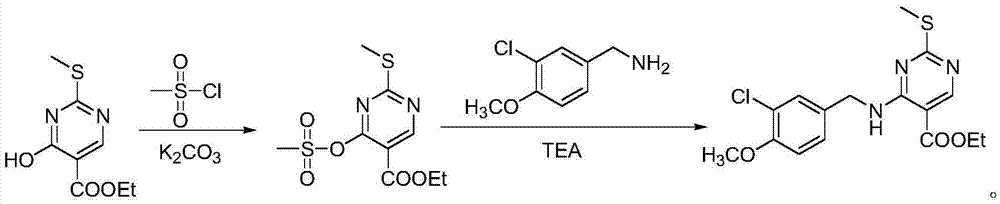

Preparation method of Avanafil intermediate

InactiveCN105439964AReduce dosageSafe post-processingOrganic chemistryEthyl esterMethanesulfonyl chloride

The invention provides a preparation method of an Avanafil intermediate. The preparation method comprises the following steps: dissolving 4-hydroxy-2-methylthio-ethyl 5-pyrimidinecarboxylate and potassium carbonate in DMF to obtain a mixed solution, adding methanesulfonyl chloride into the mixed solution under the stirring condition, continuously stirring after addition until a reaction is ended, adding water and ethyl acetate into a reaction solution, carrying out extraction and liquid separation, carrying out vacuum concentration on an organic phase to prepare 4-methanesulfonic sulfonic ester-2-methylthio-ethyl 5-pyrimidinecarboxylate; dissolving the obtained 4-methanesulfonic sulfonic ester-2-methylthio-ethyl 5-pyrimidinecarboxylate into DMF, adding a (3-chloro-4-methoxy)Benzylamine hydrochloride to obtain mixed liquor, adding triethylamine into the mixed liquor under the stirring condition, continuously stirring after addition until a reaction is ended, adding water and ethyl acetate, carrying out extraction and liquid separation, carrying out vacuum concentration on an organic phase, and recrystallizing to prepare 4-(3-chloro-4-methoxybenzylamino)-5- ethyloxycarbonyl-2-methylthiopyrimidine. The invention has advantages of less environmental pollution, high product yield, safe post-processing and simple operation.

Owner:HEBEI UNIVERSITY

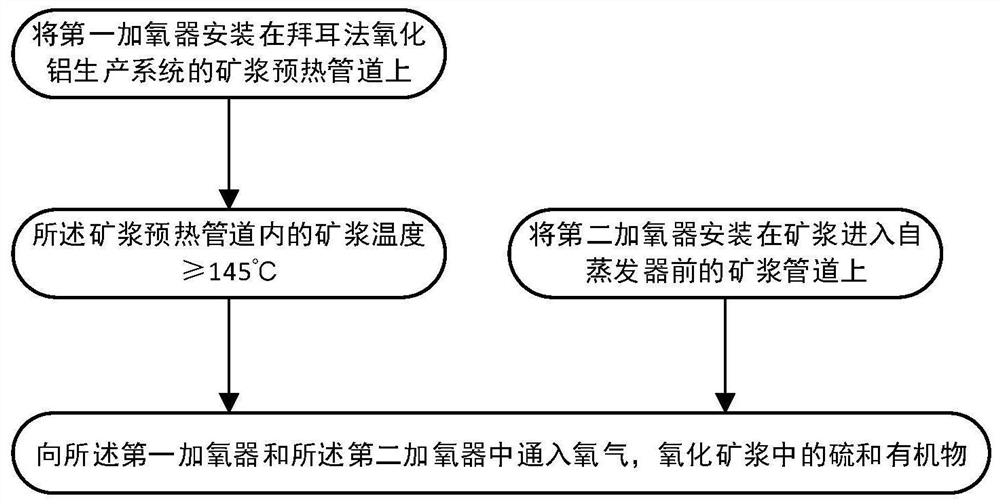

Method for synergistically and efficiently oxidizing sulfur and organic matters in bauxite dissolution slurry

ActiveCN112299460AShort reaction timeLow investment costAluminates/aluminium-oxide/aluminium-hydroxide purificationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationMineralogyBayer process

The invention provides a method for synergistically and efficiently oxidizing sulfur and organic matters in bauxite dissolved slurry, and belongs to the technical field of aluminum oxide production. The method comprises the following steps that a first oxygenator is arranged on an ore pulp preheating pipeline of a Bayer process aluminum oxide production system, wherein the temperature of ore pulpin the ore pulp preheating pipeline is more than or equal to 145 DEG C; a second oxygenator is installed on an ore pulp pipeline before ore pulp enters a self-evaporator; and oxygen is introduced intothe first oxygenator and the second oxygenator to oxidize sulfur and organic matters in the ore pulp. The method not only can efficiently remove sulfur in the bauxite dissolution slurry, but also canefficiently remove organic matters in the bauxite dissolution slurry.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

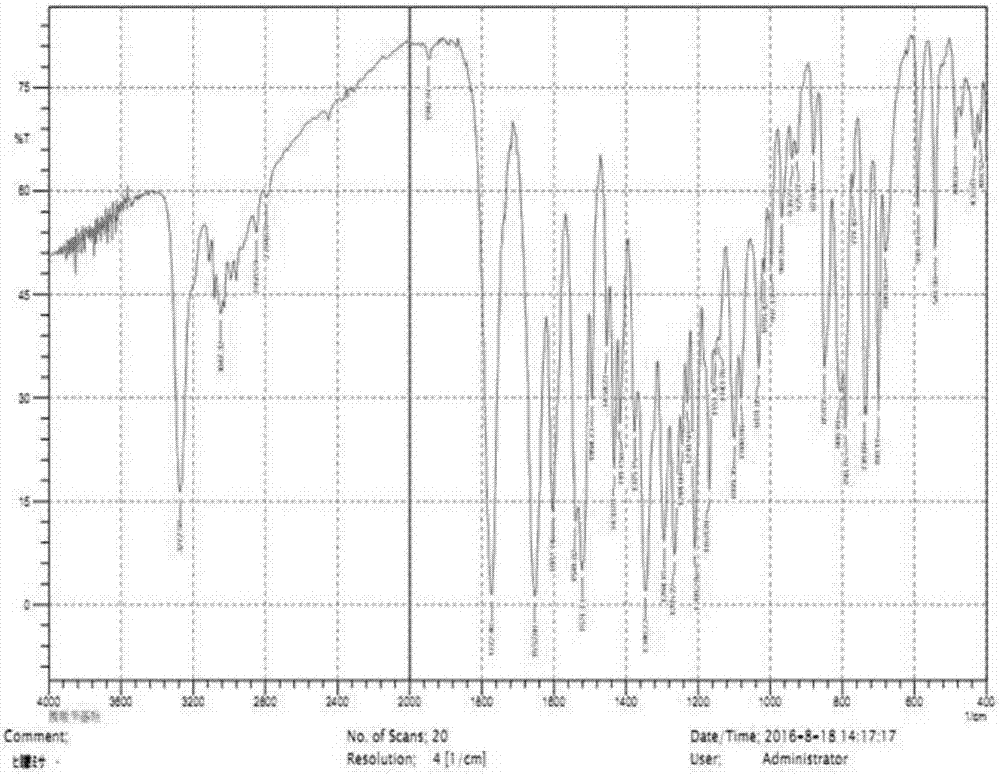

Method for preparing 7-phenylacetylamino-3-hydroxyl-3-cyclo-4-p-nitrobenzyl cephalosporin carboxylate

InactiveCN107056817AEasy to getReduced overall reaction timeOrganic chemistryRoom temperatureThiazoline

The invention belongs to the field of preparation methods for compounds and particularly relates to a method for preparing 7-phenylacetylamino-3-hydroxyl-3-cyclo-4-p-nitrobenzyl cephalosporin carboxylate. The 7-phenylacetylamino-3-hydroxyl-3-cyclo-4-p-nitrobenzyl cephalosporin carboxylate is prepared from thiazoline enol ester, which serves as a raw material, by a one-pot method through acylation, ene-amination, bromization and cyclization. According to the method, through one-pot method continuous reactions, the operation is simple, the total reaction time is shortened, and the energy consumption is greatly lowered; and the reaction process is carried out at normal temperature or under the condition of being close to room temperature, the reaction conditions are mild, the reaction time is relatively short, the raw materials used are readily available, the cost is low, the pollution is light, the total yield reaches 82.5% or more, the purity can reach 98.0% or more, and the quality of the product is relatively good, so that the method is applicable to industrial production.

Owner:SHAXING CHEM TAIZHOU CITY

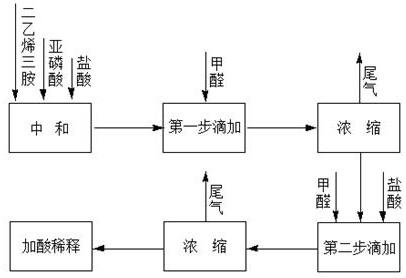

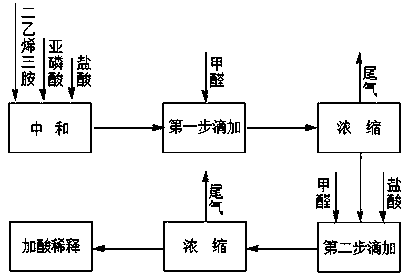

Production process of diethylenetriaminepenta(methylene-phosphonic acid)

ActiveCN110804071AReduce dosageInhibitionGroup 5/15 element organic compoundsPhosphorous acidDiethylenetriamine

The invention discloses a production process of diethylenetriaminepenta(methylene-phosphonic acid). The production process comprises the following specific operation steps: (1) adding metered hydrochloric acid, diethylenetriamine and phosphorous acid into a reactor in order, performing continuous stirring in the reactor, and maintaining the temperature at <=50 DEG C; (2) performing heating to a certain temperature, adding a part of a formaldehyde aqueous solution dropwise at different flow rates, after the addition is completed, performing heat preservation, and performing concentration; and (3) adding hydrochloric acid, performing heating to 110-120 DEG C, adding the remaining formaldehyde aqueous solution dropwise, after the addition is completed, performing heat preservation for a reaction, performing evaporation, performing dilution, performing cooling, and adjusting the pH to obtain the qualified finished product. The method accelerates the reaction rate, not only effectively inhibits the production of by-product hydroxymethylphosphonic acid, improves the conversion rate and product yield of the effective active component diethylenetriaminepenta(methylene-phosphonic acid), butalso shortens the total reaction time, and reduces the production costs; and the method is simple, safe, and easy to operate, and is beneficial to industrial production.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

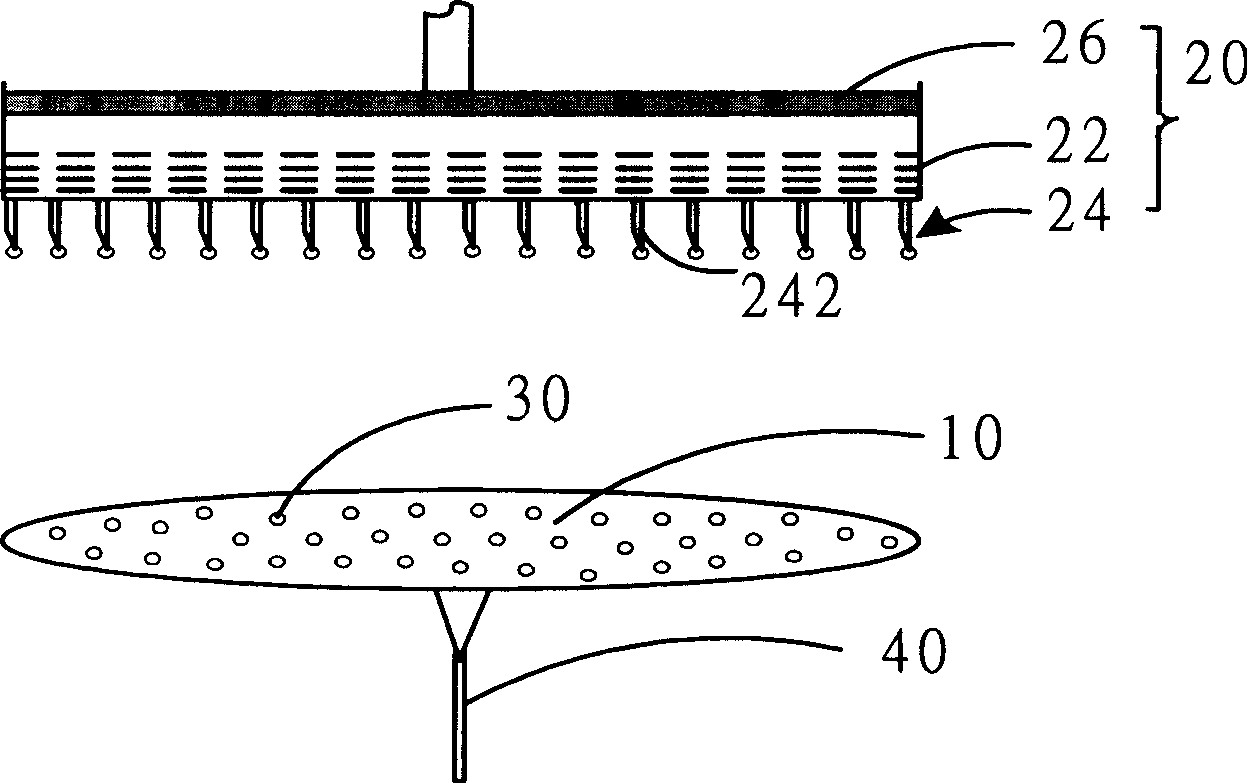

Production method of nano-carbon tube

The invention discloses a growing method of nanometer carbon pipe, which comprises the following steps: providing base; preparing nanometer catalyst solution with certain viscosity; dripping nanometer catalyst solution on the base surface through injecting device of micrometer-grade injecting needle array; forming catalyst layer; growing nanometer carbon pipe on the base surface; making catalyst drip as micrometer grade.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

A method for preparing aluminum nitride

ActiveCN106882773BReduce the temperatureReduced overall reaction timeNitrogen compoundsCrucibleCarbide

The invention discloses a preparation technology of aluminum nitride. The preparation technology comprises the following two stages of 1, using aluminum oxide and carbon as raw materials, performing carbon thermal reduction reaction under the vacuum and high temperature conditions, and forming a solid product mainly containing aluminum carbide and aluminum oxycarbide; 2, using the product in the stage 1 as a raw material, grinding, putting into a carbon crucible or mixing with a small amount of carbon raw material, and performing high-temperature nitridation reaction under the nitrogen atmosphere, so as to obtain the aluminum nitride. The preparation technology has the advantages that the required temperature is lower, the reaction time is shorter, the carbon content in the obtained aluminum nitride powder is low, and the subsequent carbon step can be shortened or avoided; besides carbon monoxide, the other waste gases are not produced; the industrializing is easily realized.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of 7-phenylacetamido alkane acid

The invention relates to a preparation method of a compound intermediate, and specifically relates to a preparation method of 7-phenylacetamido alkane acid. According to the preparation method, penicillin potassium salts are taken as the raw material, and an enzyme catalyst and an oxidant are added into a solvent in sequence to carry out catalytic oxidation reactions to obtain 7-phenylacetamido alkane acid. In the conventional technology, there are multiple steps; while in the provided preparation method, there is only one step, so the total reaction time is shortened, and the energy consumption is largely reduced. The reactions are carried out at a room temperature or a temperature close to the room temperature; the reaction conditions are mild, the reaction time is short, the using amount of catalyst is little; the preparation method is environment-friendly and generates little pollution; moreover, the operation is simple, the cost is low, the yield can reach 90.0%, the purity can reach 98.0%; the product quality is good, prominent economic benefits and social benefits are generated, and the preparation method is suitable for industrial production.

Owner:SHAXING CHEM TAIZHOU CITY

Method for synthesizing persantine intermediate 2,4,6,8-tetrahydroxy pyrimido[5,4-d] pyrimidine

ActiveCN101899046BFewer filtering stepsShorten the timeOrganic chemistryUrea derivativesTemperature control

The invention relates to a method for synthesizing a persantine intermediate 2,4,6,8-tetrahydroxy pyrimido[5,4-d] pyrimidine, comprising the following steps of: (1) adding nitro orotic acid in an alkali liquid, then hydrogenating with Ni / H2, and filtering to obtain an amino orotic acid solution which is directly used for next reaction without separation; (2) adjusting pH of the amino orotic acid solution with concentrated hydrochloric acid to 3, adding sodium cyanate for temperature control reaction to obtain the urea derivatives of the amino orotic acid; then dropping a 30% sodium hydroxide solution to adjust pH to 13, heating for cyclization, dropping a 50-60% sulfuric acid solution to adjust pH to 3; (3) cooling to room temperature, filtering, washing to neutrality and drying to obtainthe product. The intermediate of step (1) is not needed to separate, thereby saving a lot of time and labor, reducing about 50% of total reaction time with mild reaction condition and maximum reaction temperature reduced to 95 DEG C so that the device is less required and more durable.

Owner:ZHEJIANG HUABANG MEDICAL & CHEM

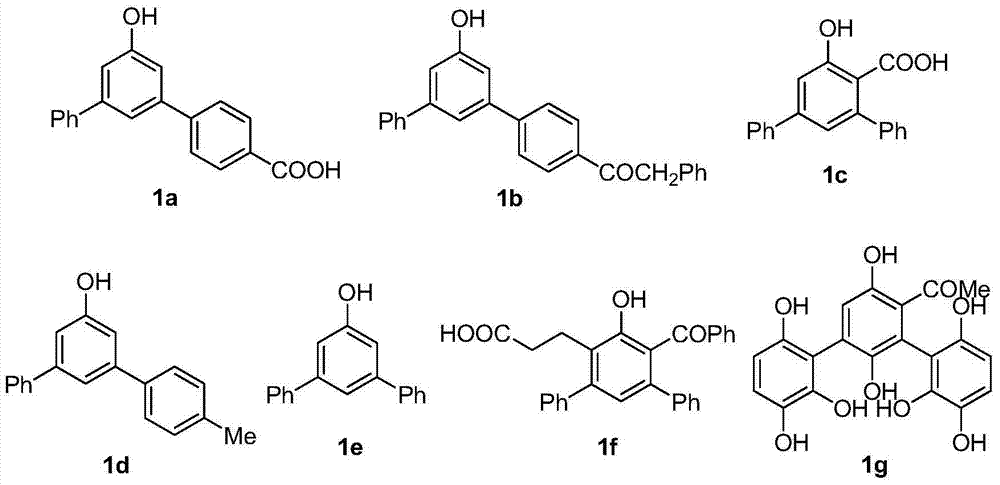

Method for synthesizing 3,5-diphenyl phenol

InactiveCN104744218AEasy accessLow costOrganic chemistryOrganic compound preparationPhenolsPhenol derivative

The invention discloses a method for synthesizing 3,5-diphenyl phenol in one pot by two steps. The method comprises the following steps: by taking ethyl acetoacetate as a raw material, fluorinating by using a fluorinating agent SelectfluorTM; cyclizing with chalcone Robinson to generate a fluorine-containing cyclohexenone midbody; subsequently continuously performing dehydrofluorination, aromatization and hydrolysis decarboxylation to generate a final product 3,5-diphenyl phenol. The method is simple to operate, capable of reducing the difficulty of after-treatment, high in reaction selectivity, cheap in raw material, good in substrate adaptability and capable of shortening the total reaction time of a traditional method from 30h to 4h and increasing the total yield from 20% to above 80%. A 3,5-diaryl phenol derivative is an important medicine midbody, and the special molecular structure thereof has quite important bioactivity and can be used for preparing 'Molecular Harpoon'.

Owner:NANJING UNIV OF SCI & TECH

Production method of nano-carbon tube

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

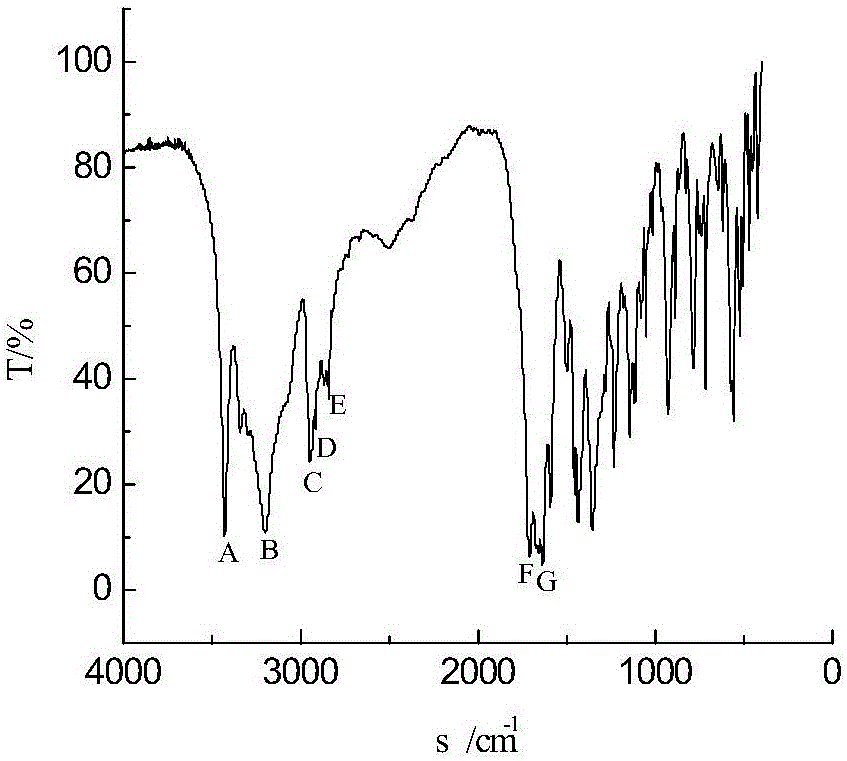

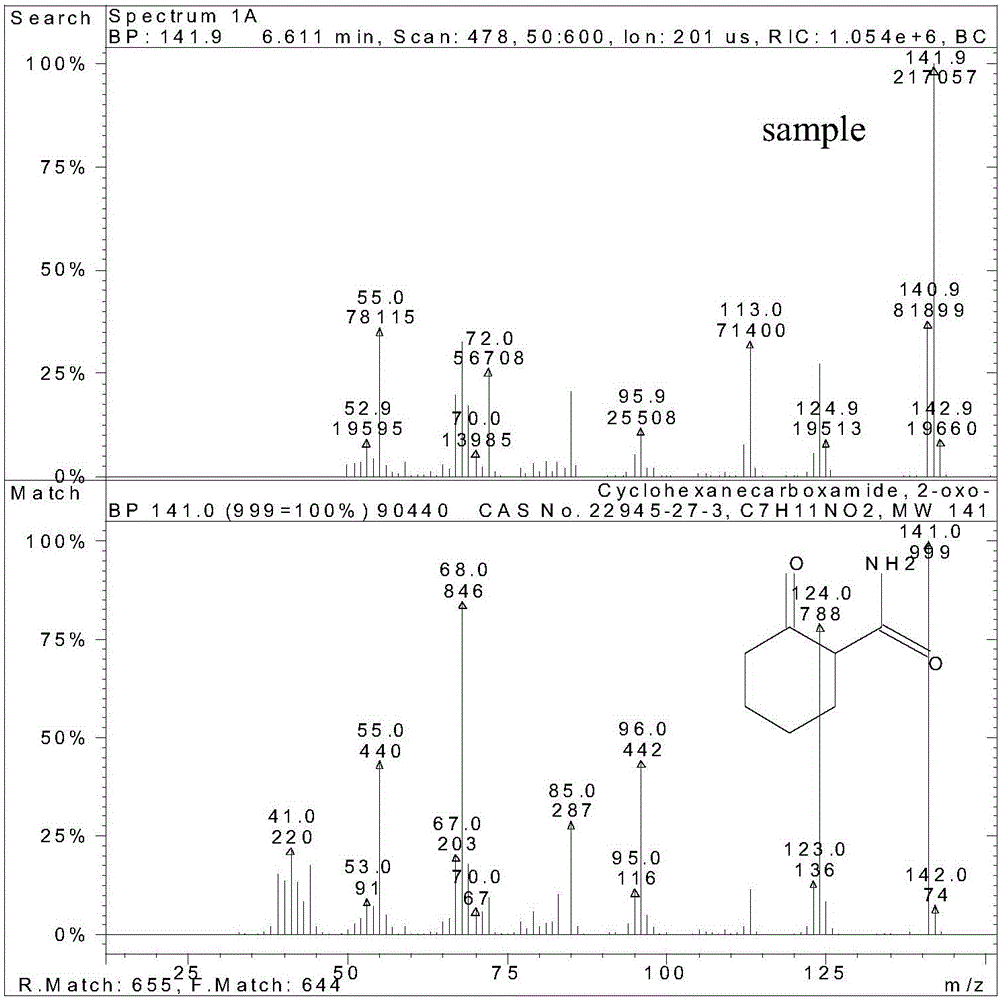

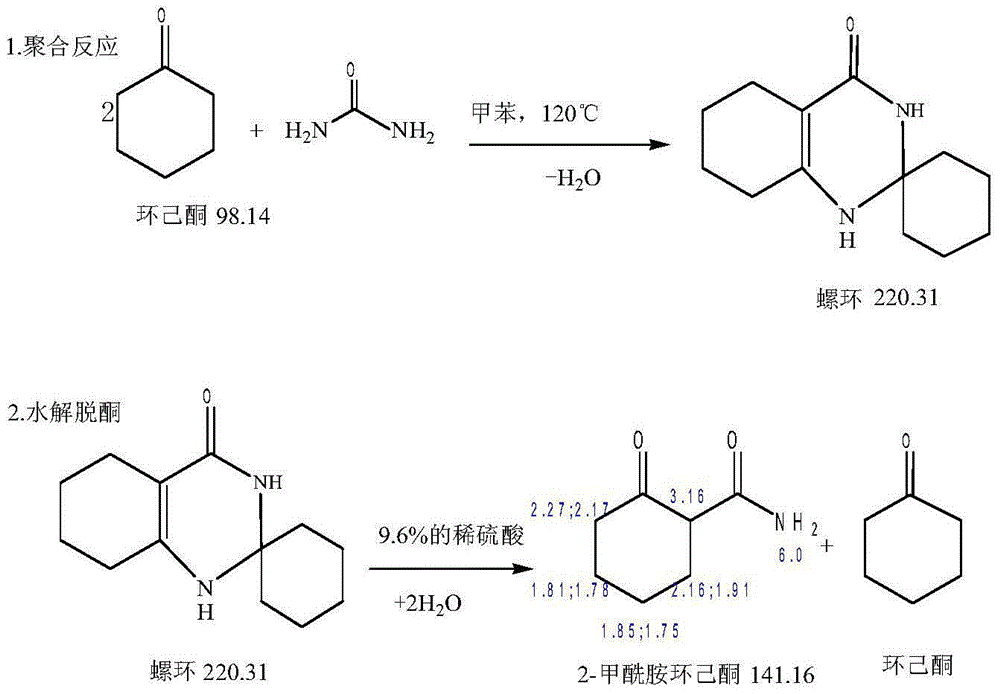

A kind of method of synthesizing 2-carboxamide cyclohexanone

InactiveCN103664682BReduce energy consumptionIncrease profitOrganic compound preparationCarboxylic acid amides preparationCyclohexanoneOrganic synthesis

The invention discloses a synthetic method for 2-formamide cyclohexanone with low emission and low consumption, and belongs to the technical field of medicinal chemistry and organic synthesis. According to the method, a non-oxide proton acid or salt thereof is used as a catalyst, arene is used as a solvent and a water-carrying agent, and cyclohexanone and urea are used as raw materials, so that the 2-formamide cyclohexanone can be prepared through a one-pot reaction. The screw ring synthetized through the technology provided by the invention is not needed to be cooled and separated, so that a great amount of scouring water is eliminated; besides, condensation generated water saturated by cyclohexanone, evaporated water generated during the screw ring hydrolysis and aqueous phase mother solution generated after the product is separated out are used for preparing hydrolyzing diluted acid to realize cyclic utilization, so that the loss caused by the cyclohexanone dissolution in water is eliminated, the use ratio of cyclohexanone is increased and the zero release of sewage is realized; the method is simple and convenient to operate and is suitable for industrial application.

Owner:CHINA UNIV OF MINING & TECH

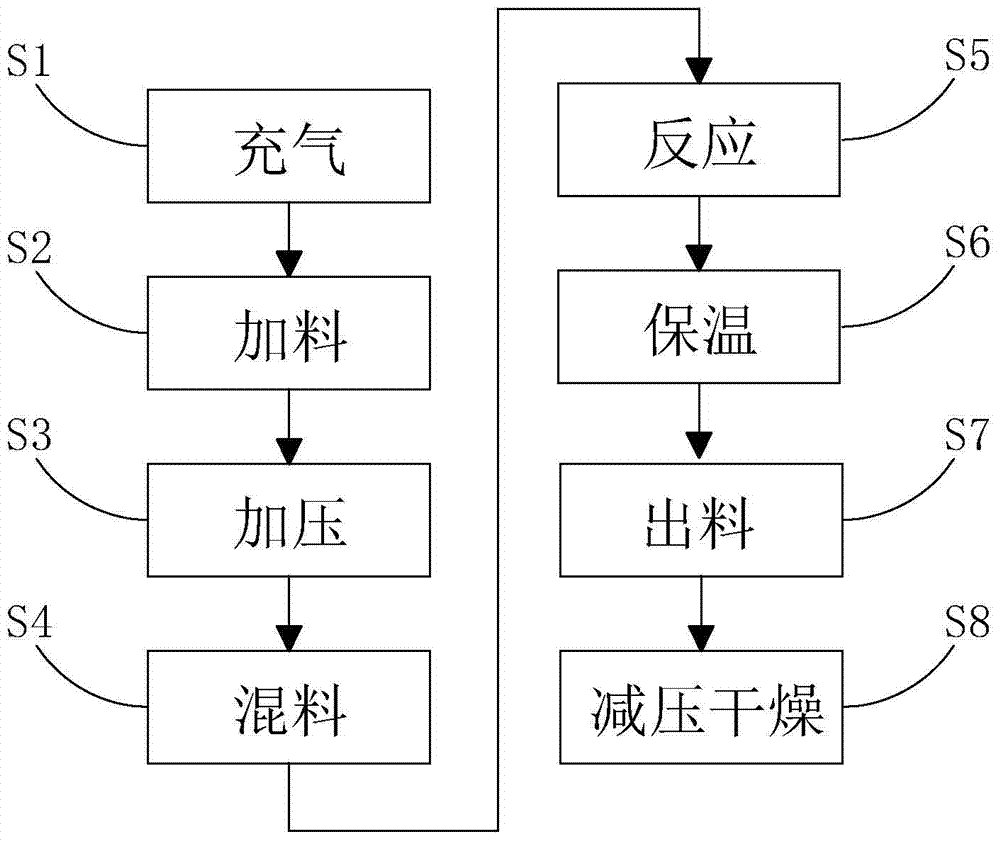

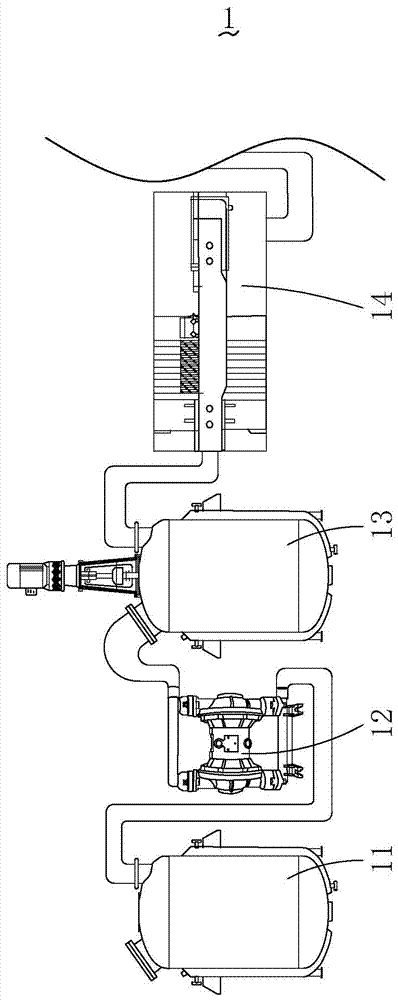

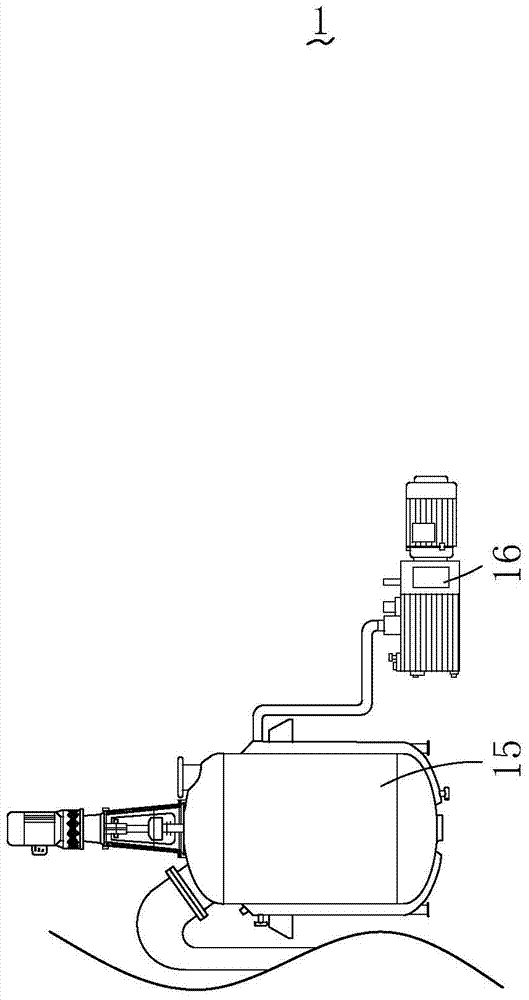

Bisoxalate preparation device and preparation method thereof

ActiveCN105037148BReduce manufacturing costRaise the reaction temperaturePreparation from carboxylic acid halidesOrganic compound preparationOxalateDiaphragm pump

The invention provides a bis(2,4,5-trichloro-6-carbopentoxyphenyl)oxalate preparation device and method. The bis(2,4,5-trichloro-6-carbopentoxyphenyl)oxalate preparation device comprises a feeding kettle, a diaphragm pump, a reaction kettle, a filter press, a distillation still and a vacuum pump. The feeding kettle, the diaphragm pump, the reaction kettle, the filter press, the distillation still and the vacuum pump are sequentially connected. The bis(2,4,5-trichloro-6-carbopentoxyphenyl)oxalate preparation method includes the following steps of inflation, feeding, pressurizing, mixing, reacting, heat preserving, discharging, and decompressing and drying. The bis(2,4,5-trichloro-6-carbopentoxyphenyl)oxalate preparation device and method solve the technical problems that a bis(2,4,5-trichloro-6-carbopentoxyphenyl)oxalate preparation method in the prior art is slow in reaction and low in yield.

Owner:山东博苑医药化学股份有限公司

A method for preparing oxidized cellulose for hemostasis in the process of oxidative degumming of ramie

ActiveCN106478825BChange structureWith hemostatic functionSurgical adhesivesPharmaceutical delivery mechanismFiberOrganosolv

The invention provides a method for preparing bleeding stopping oxidized celluloses in ramie oxidation degumming procedures. The method includes smashing raw ramie to obtain short fibers and soaking the short fibers to sufficiently moisten the short fibers and allow the short fibers to sufficiently swell; mixing the pretreated raw ramie short fibers and degumming solution with one another to obtain mixtures, heating the mixtures, then preserving heat, sufficiently removing colloid in the raw ramie by the aid of oxidability of specific oxidizing agents and simultaneously oxidizing celluloses with active hydroxyl to obtain oxidized celluloses with a large quantity of carboxyl; soaking oxidized and treated fibers by the aid of organic solvent aqueous solution and removing the unreacted oxidizing agents; separating the oxidized celluloses from water and carrying out drying treatment on the oxidized celluloses to ultimately obtain the powdery bleeding stopping oxidized celluloses. The method has the advantages that processes are simple, the original two working procedures are combined into a single working procedure, accordingly, the total reaction time can be shortened, medicines and the cost can be saved, and the efficiency can be greatly improved; the bleeding stopping oxidized celluloses which are products prepared by the aid of the method are high in bleeding stopping speed and bleeding stopping efficiency and can be widely applied to quickly stopping bleeding under conditions of war wound, trauma and the like, and stable effects can be realized.

Owner:DONGHUA UNIV

A kind of production method of diethylenetriaminepentamethylenephosphonic acid

ActiveCN110804071BReduce dosageInhibitionGroup 5/15 element organic compoundsPhosphorous acidReaction rate

The invention discloses a production process of diethylenetriaminepentamethylenephosphonic acid. The specific operation steps include: (1) Add the measured hydrochloric acid, diethylenetriamine and phosphorous acid into the reaction kettle in sequence, and the reaction kettle is continuously stirred to keep the temperature ≤ 50°C; (2) Raise the temperature to a certain temperature, and add dropwise at different flow rates Part of the formaldehyde solution, after the dropwise addition, keep warm, concentrate; (3) add hydrochloric acid and raise the temperature to 110~120°C, add the remaining formaldehyde solution dropwise, after the dropwise addition, keep warm for reaction, steam externally, dilute, cool down, adjust Sour qualified finished product. The invention accelerates the reaction rate, not only effectively suppresses the production of the by-product hydroxymethylphosphonic acid, improves the conversion rate and product yield of the effective active component diethylenetriaminepentamethylenephosphonic acid, but also shortens the total reaction time. time, reducing production costs. The process method is simple, safe and easy to operate, and is beneficial to industrialized production.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

Method for preparing spinnable cellulosic fibers based on hydrogen bond depolymerization principle

InactiveCN110003500AThe operation process is simpleIncrease productivityMonocomponent cellulose artificial filamentSolventChemistry

The invention discloses a method for preparing spinnable cellulosic fibers based on a hydrogen bond depolymerization principle. The method comprises the steps that a cellulosic raw material is added into a reaction solvent, through heating stirring, intramolecular and intermolecular strong hydrogen bonds which are bonded closely in the cellulosic raw material are depolymerized, cellulose, obtainedafter the hydrogen bonds are depolymerized, of a loose structure is placed in a cell crusher and subjected to cooperative treatment of the chemical action and the mechanical action, and the spinnablecellulosic fibers are obtained. In the method, the green solvent is adopted, the technological process is short, the efficiency is high, the production process is free of pollution, and the method isenergy-saving, environmentally friendly, low in cost and high in yield of the spinnable cellulosic fiber.

Owner:MINJIANG UNIV

A kind of synthetic method of 1,3-dinitrohalobenzene compound

ActiveCN109970566BDropping time is longLong reaction heatSequential/parallel process reactionsChemical/physical/physico-chemical microreactorsNitrationEnvironmental engineering

The present invention provides the synthetic method of 1,3-dinitrohalobenzene compound, comprises the following steps: A) halobenzene compound, and the mixed acid of nitric acid, sulfuric acid, carry out the first nitration reaction in one-stage continuous flow microreactor , through oil-water separation, to obtain a nitrohalobenzene compound and the first waste acid; B) diverting the mononitrohalobenzene compound into the secondary continuous flow microreactor, and carrying out the second nitration reaction with the mixed acid of nitric acid and sulfuric acid , the nitration mixture generated is quenched and filtered at the outlet of the secondary continuous flow microreactor to obtain 1,3-dinitrohalobenzene compound and the second waste acid; C) the second waste acid is recycled to the first-level continuous flow In the microreactor, carry out the third nitration reaction with the halobenzene compound, and separate the oil and water to obtain the mononitrohalobenzene compound and the third waste acid; repeat steps B), C); the halobenzene compound has the formula I structure. Short reaction time and less waste acid realize continuous production.

Owner:SHANDONG HIMILE CHEM TECH

A kind of preparation method of avanafil intermediate

InactiveCN105439964BReduce dosageSafe post-processingOrganic chemistryEthyl esterMethanesulfonyl chloride

The invention provides a preparation method of an Avanafil intermediate. The preparation method comprises the following steps: dissolving 4-hydroxy-2-methylthio-ethyl 5-pyrimidinecarboxylate and potassium carbonate in DMF to obtain a mixed solution, adding methanesulfonyl chloride into the mixed solution under the stirring condition, continuously stirring after addition until a reaction is ended, adding water and ethyl acetate into a reaction solution, carrying out extraction and liquid separation, carrying out vacuum concentration on an organic phase to prepare 4-methanesulfonic sulfonic ester-2-methylthio-ethyl 5-pyrimidinecarboxylate; dissolving the obtained 4-methanesulfonic sulfonic ester-2-methylthio-ethyl 5-pyrimidinecarboxylate into DMF, adding a (3-chloro-4-methoxy)Benzylamine hydrochloride to obtain mixed liquor, adding triethylamine into the mixed liquor under the stirring condition, continuously stirring after addition until a reaction is ended, adding water and ethyl acetate, carrying out extraction and liquid separation, carrying out vacuum concentration on an organic phase, and recrystallizing to prepare 4-(3-chloro-4-methoxybenzylamino)-5- ethyloxycarbonyl-2-methylthiopyrimidine. The invention has advantages of less environmental pollution, high product yield, safe post-processing and simple operation.

Owner:HEBEI UNIVERSITY

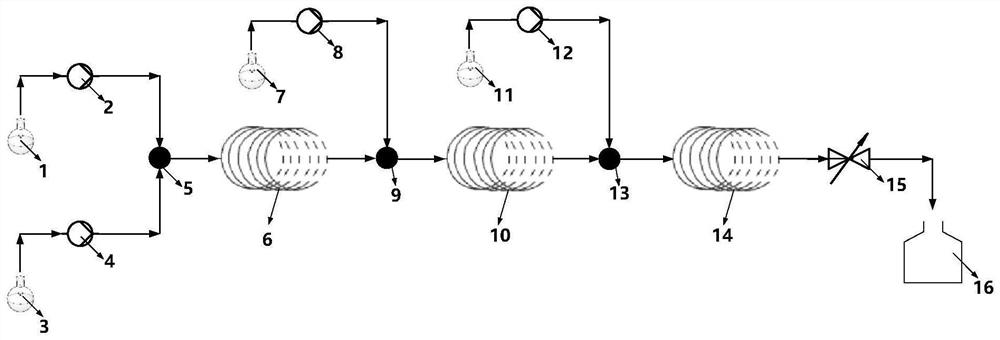

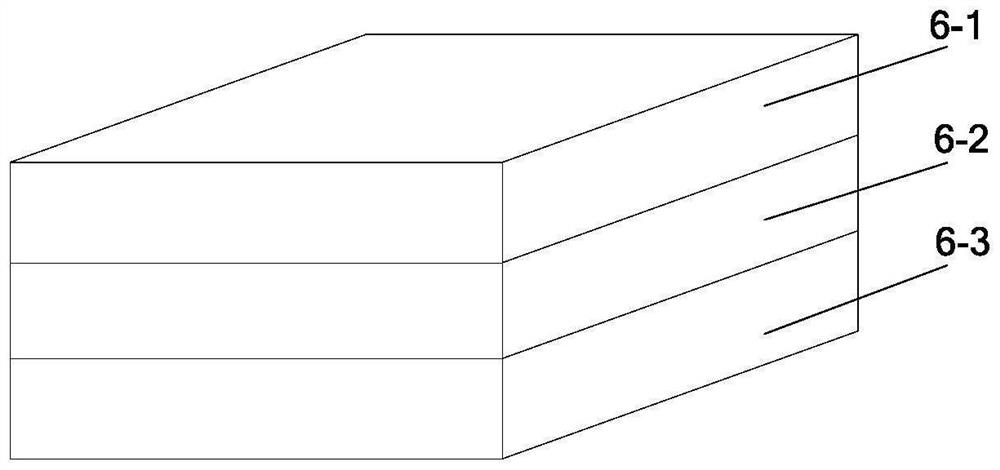

Continuous flow synthesis method of (3aS, 6aR)-lactone

PendingCN114560865AHigh yieldHigh optical purityOrganic chemistryChemical/physical/physico-chemical microreactorsPropanediolBorohydride

The invention discloses a continuous flow preparation method of (3aS, 6aR)-lactone. The method comprises the following steps: respectively and simultaneously pumping a cyclic anhydride substrate solution and a chiral auxiliary agent propylene glycol solution into a first micro-mixer, mixing, and carrying out a continuous desymmetry reaction in a first micro-channel reactor; after the reactant flows out, the reactant and a hydroboron solution are mixed in a second micro-mixer and then enter a second micro-channel reactor to be subjected to a continuous reduction reaction, the flowing-out mixed reaction material and an inorganic mineral acid solution are mixed in a third micro-mixer and then enter a third micro-channel reactor to be subjected to a continuous ring closing reaction, and the target product (3aS, 6aR)-lactone is prepared. The total product yield is gt; 90%, the enantiomeric excess percentage (ee) gt; 99%. Compared with the prior art, the method is short in reaction time, high in product yield and optical purity, high in automation degree, high in technological process continuous efficiency, low in energy consumption and easy to industrially amplify.

Owner:FUDAN UNIV

A kind of treatment method of selenium-containing wastewater

ActiveCN104556543BIncreased toxicityLow toxicityWater contaminantsMultistage water/sewage treatmentFlocculationWastewater

The invention discloses a treatment method of selenium-containing wastewater. The treatment method comprises the following steps: regulating the pH of the selenium-containing wastewater to 8-10, and carrying out ozonation in an ozone reactor to oxidize a selenite ion (SeO3<2->) into a selenate radical ion (SeO4<2->); carrying out aerobic biological treatment, regulating the pH to 3-5, and carrying out chitosan (CTS) adsorption; finally feeding the product into a flocculation sedimentation tank, adding a flocculant, stirring, and carrying out solid-liquid separation, so as to obtain wastewater without selenium. The treatment method has the beneficial effects that the removal rate of the selenium in the wastewater is high, the application range is wide, and the operation is easy and convenient.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for synthesizing persantine intermediate 2,4,6,8-tetrahydroxy pyrimido[5,4-d] pyrimidine Method for synthesizing persantine intermediate 2,4,6,8-tetrahydroxy pyrimido[5,4-d] pyrimidine](https://images-eureka.patsnap.com/patent_img/c6be5a22-6876-4ac6-8df6-4c9881f7f5c1/B2009100519991D0000011.PNG)

![Method for synthesizing persantine intermediate 2,4,6,8-tetrahydroxy pyrimido[5,4-d] pyrimidine Method for synthesizing persantine intermediate 2,4,6,8-tetrahydroxy pyrimido[5,4-d] pyrimidine](https://images-eureka.patsnap.com/patent_img/c6be5a22-6876-4ac6-8df6-4c9881f7f5c1/B2009100519991D0000021.PNG)

![Method for synthesizing persantine intermediate 2,4,6,8-tetrahydroxy pyrimido[5,4-d] pyrimidine Method for synthesizing persantine intermediate 2,4,6,8-tetrahydroxy pyrimido[5,4-d] pyrimidine](https://images-eureka.patsnap.com/patent_img/c6be5a22-6876-4ac6-8df6-4c9881f7f5c1/B2009100519991D0000031.PNG)

![Method for synthesizing persantine intermediate 2,4,6,8-tetrahydroxy pyrimido[5,4-d] pyrimidine Method for synthesizing persantine intermediate 2,4,6,8-tetrahydroxy pyrimido[5,4-d] pyrimidine](https://images-eureka.patsnap.com/patent_img/20ecacef-39e4-4e89-9403-ea1496118337/FSB00000706483700011.PNG)

![Method for synthesizing persantine intermediate 2,4,6,8-tetrahydroxy pyrimido[5,4-d] pyrimidine Method for synthesizing persantine intermediate 2,4,6,8-tetrahydroxy pyrimido[5,4-d] pyrimidine](https://images-eureka.patsnap.com/patent_img/20ecacef-39e4-4e89-9403-ea1496118337/G2009100519991D00011.PNG)

![Method for synthesizing persantine intermediate 2,4,6,8-tetrahydroxy pyrimido[5,4-d] pyrimidine Method for synthesizing persantine intermediate 2,4,6,8-tetrahydroxy pyrimido[5,4-d] pyrimidine](https://images-eureka.patsnap.com/patent_img/20ecacef-39e4-4e89-9403-ea1496118337/G2009100519991D00021.PNG)