A kind of production device and production method of liquid forma sodium

A production method and technology of sodium formazate, which are applied in the production equipment of liquid sodium formamic acid and its synthesis field, can solve the problems of hydrochloric acid or raw materials, high product cost, high loss of carbon disulfide, etc., so as to avoid blockage of venting pipeline and safety Problems, product comprehensive cost reduction, and the effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

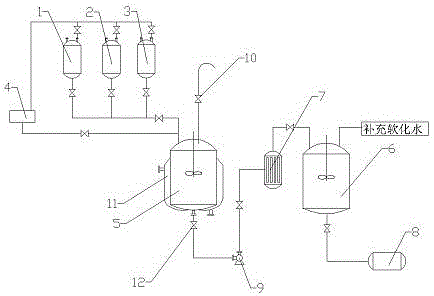

[0033] Example 1, such as figure 1 Shown, a kind of production device of liquid formazan comprises reactor 5, and the top of described reactor 5 is connected with dimethylamine elevated tank 1, sulfur dioxide elevated tank 2, sodium hydroxide elevated tank 3 respectively by pipeline, so The bottom of the reactor 5 is connected with a reactor discharge valve 12, and the reactor discharge valve 12 is connected with a filter 7, a finished product blending tank 6 and a finished product storage tank 8 in sequence through pipelines.

[0034] The outside of the reaction kettle 5 is provided with a reaction kettle jacket and an internal cooling coil.

[0035] A circulation pump 9 is installed on the communication pipeline between the reactor discharge valve 12 and the filter 7 .

[0036] Said dimethylamine elevated tank 1, sulfur dioxide elevated tank 2, sodium hydroxide elevated tank 3 and the connecting pipeline between the reactor 5 are connected in parallel with an air compressor...

Embodiment 2

[0052] Example 2, such as figure 1 Shown, a kind of production device of liquid formex sodium comprises reactor 5, and the top of described reactor 5 is connected with dimethylamine elevated tank 1, sulfur dioxide elevated tank 2, sodium hydroxide elevated tank 3 respectively by pipeline, so The bottom of the reaction kettle 5 is connected with a reactor discharge valve 12, and the reactor discharge valve 12 is connected with a filter 7, a finished product preparation tank 6 and a finished product storage tank 8 in sequence through pipelines.

[0053] The outside of the reaction kettle 5 is provided with a reaction kettle jacket and an internal cooling coil.

[0054] A circulation pump 9 is installed on the communication pipeline between the reactor discharge valve 12 and the filter 7 .

[0055] An air compressor 4 is communicated with the connecting pipeline between the dimethylamine elevated tank 1, the sulfur dioxide elevated tank 2, the sodium hydroxide elevated tank 3 and ...

Embodiment 3

[0071] Example 3, such as figure 1 Shown, a kind of production device of liquid formazan comprises reactor 5, and the top of described reactor 5 is connected with dimethylamine elevated tank 1, sulfur dioxide elevated tank 2, sodium hydroxide elevated tank 3 respectively by pipeline, so The bottom of the reactor 5 is connected with a reactor discharge valve 12, and the reactor discharge valve 12 is connected with a filter 7, a finished product blending tank 6 and a finished product storage tank 8 in sequence through pipelines.

[0072] The outside of the reaction kettle 5 is provided with a reaction kettle jacket and an internal cooling coil.

[0073] A circulation pump 9 is installed on the communication pipeline between the reactor discharge valve 12 and the filter 7 .

[0074] An air compressor 4 is communicated with the connecting pipeline between the dimethylamine elevated tank 1, the sulfur dioxide elevated tank 2, the sodium hydroxide elevated tank 3 and the reactor 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com