An Optical Diffusion Film

A technology of optical diffusion and light diffusion layer, applied in the field of optical diffusion film, can solve the problems of insufficient bonding fastness of protective film, insufficient fastness of protective film, no anti-static effect, etc., and achieve good anti-static effect and moderate surface tension. The effect of high surface flatness and improved film fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

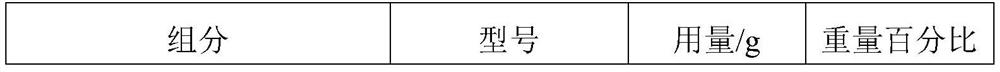

[0061] An optical diffusion film, comprising a transparent substrate, a light diffusion layer arranged on the upper surface of the transparent substrate, and a back layer arranged on the lower surface of the transparent substrate, the composition and weight percentage of the coating liquid of the back layer are as follows, the The back layer coating liquid was coated on the other surface of the PET substrate provided with the optical diffusion layer so that the anti-adhesion particles protruded from the back layer to a height of 2 μm. The performance of the optical diffusion film was tested, and the results are shown in Table 1.

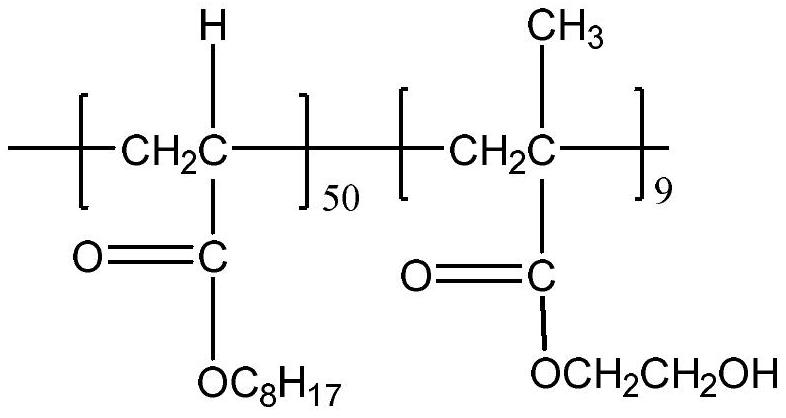

[0062] Leveling agent (acrylic ester copolymer with formula (I) structure, wherein R 1 for hydrogen, R 2 C8 straight chain alkyl, R 3 is methyl, R 4 Be hydroxyethyl, x is 50, y is 9, relative molecular weight is 10370):

[0063]

[0064] —(CH 2 CHCOOC 8 h 17 ) 50 —(CH 2 CCH 3 COOCH 2 CH 2 Oh) 9 —

[0065]

[0066]

Embodiment 2

[0068] An optical diffusion film, comprising a transparent substrate, a light diffusion layer arranged on the upper surface of the transparent substrate, and a back layer arranged on the lower surface of the transparent substrate, the composition and weight percentage of the coating liquid of the back layer are as follows, the The back layer coating liquid was coated on the other surface of the PET substrate provided with the optical diffusion layer, so that the anti-adhesion particles protruded from the back layer to a height of 1 μm. The performance of the optical diffusion film was tested, and the results are shown in Table 1.

[0069]Leveling agent (acrylic ester copolymer with formula (I) structure, wherein R 1 for hydrogen, R 2 C7 branched chain alkyl, R 3 for hydrogen, R 4 Be hydroxypropyl, x is 53, y is 8, relative molecular weight is 10050):

[0070]

[0071] —(CH 2 CHCOOC 7 h 15 ) 53 —(CH 2 CHCOOCH 2 CH 2 CH 2 Oh) 8 —

[0072]

[0073]

Embodiment 3

[0075] An optical diffusion film, comprising a transparent substrate, a light diffusion layer arranged on the upper surface of the transparent substrate, and a back layer arranged on the lower surface of the transparent substrate, the composition and weight percentage of the coating liquid of the back layer are as follows, the The back layer coating solution was coated on the other surface of the PET substrate provided with the optical diffusion layer so that the anti-adhesion particles protruded from the back layer to a height of 1.5 μm. The performance of the optical diffusion film was tested, and the results are shown in Table 1.

[0076] Leveling agent (acrylic ester copolymer with formula (I) structure, wherein R 1 is methyl, R 2 C6 straight chain alkyl, R 3 is methyl, R 4 For epoxy group, x is 58, y is 8, relative molecular weight is 10884):

[0077]

[0078] —(CH 2 CCH 3 COOC 6 h 13 ) 58 —(CH 2 CCH 3 COOCHCH 2 O) 8 —

[0079]

[0080]

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com