Method for preparing quantum dots by taking sublimed sulfur as sulfur source

A technology for sublimating sulfur and quantum dots, which is applied in the preparation/purification of sulfur, chemical instruments and methods, sulfur compounds, etc., can solve the problems of low quantum yield, long reaction time, and low quantum yield of sulfur quantum dots, and achieve Good dispersion, enhanced fluorescence intensity, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

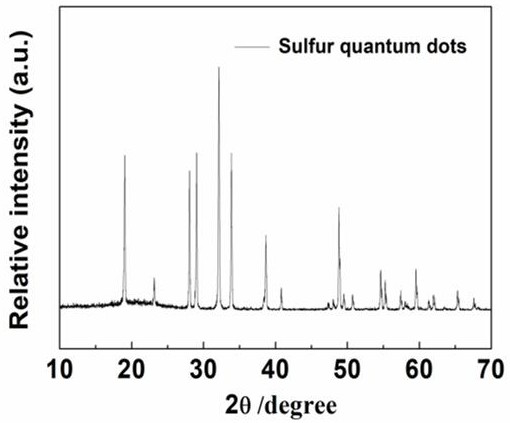

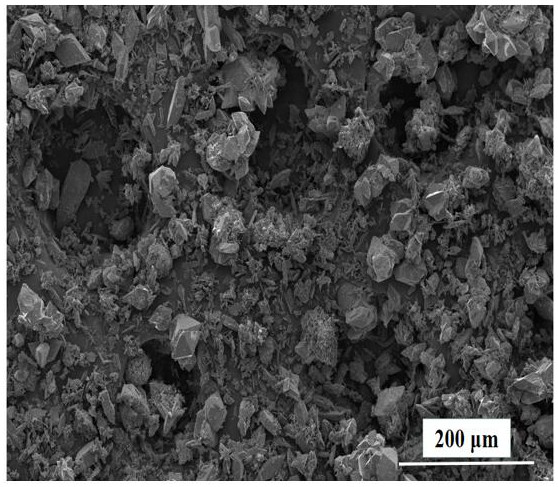

Image

Examples

Embodiment 1

[0018] This embodiment provides a method for preparing quantum dots using sublimated sulfur as a sulfur source, and the specific preparation method is as follows.

[0019] (1) Add 2 g of sodium hydroxide, 3 mL of polyethylene glycol (PEG-400) and 2 g of sublimed sulfur to 50 mL of deionized water, and react in a water bath at 40 °C for 45 h to obtain a mixed solution.

[0020] (2) Change the mixed solution obtained in step (1) from water bath reaction to ice bath reaction. Under stirring conditions, 10 mL of hydrogen peroxide by weight was added to prepare a sulfur quantum dot solution with blue fluorescence characteristics.

[0021] (3) Add anti-solvent acetone to settle the water-soluble sulfur quantum dots, and then centrifuge the sulfur quantum dots precipitated from the aqueous solution at a speed of 9000 r / min for 5 minutes, and freeze-dry the obtained precipitate (drying temperature - 30 °C, 12 hours), and finally white sulfur quantum dot powder was obtained.

Embodiment 2

[0023] This embodiment provides a method for preparing quantum dots using sublimated sulfur as a sulfur source, and the specific preparation method is as follows.

[0024] (1) Add 3.5 g of sodium hydroxide, 3 mL of polyethylene glycol (PEG-400) and 4 g of sublimed sulfur to 50 mL of deionized water, and react in a water bath at 60 °C for 20 h to obtain a mixed solution.

[0025] (2) Change the mixed solution obtained in step (1) from water bath reaction to ice bath reaction. Under stirring conditions, 10 mL of hydrogen peroxide by weight was added to prepare a sulfur quantum dot solution with blue fluorescence characteristics.

[0026] (3) Add anti-solvent acetone to settle the water-soluble sulfur quantum dots, and then centrifuge the sulfur quantum dots precipitated from the aqueous solution at a speed of 9000 r / min for 5 minutes, and freeze-dry the obtained precipitate (drying temperature - 30 °C, 12 hours), and finally white sulfur quantum dot powder was obtained.

Embodiment 3

[0028] This embodiment provides a method for preparing quantum dots using sublimated sulfur as a sulfur source, and the specific preparation method is as follows.

[0029] (1) Add 5 g of sodium hydroxide, 3 mL of polyethylene glycol (PEG-400) and 7 g of sublimed sulfur to 50 mL of deionized water, and react in a water bath at 70 °C for 10 h to obtain a mixed solution.

[0030] (2) Change the mixed solution obtained in step (1) from water bath reaction to ice bath reaction. Under stirring conditions, 20 mL of hydrogen peroxide by weight was added to prepare a sulfur quantum dot solution with blue fluorescent properties.

[0031] (3) Add anti-solvent acetone to settle the water-soluble sulfur quantum dots, and then centrifuge the sulfur quantum dots precipitated from the aqueous solution at a speed of 9000 r / min for 5 minutes, and freeze-dry the obtained precipitate (drying temperature - 30 °C, 15 hours), and finally white sulfur quantum dot powder was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com