Preparation method of matte release paper

A technology for release paper and preparation steps, which is applied in the field of matte release paper preparation, which can solve the problems of waste of production time, manpower and material resources, limited use occasions, low production efficiency, etc., to increase the number of release times and reduce the amount used , The effect of high demoulding times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

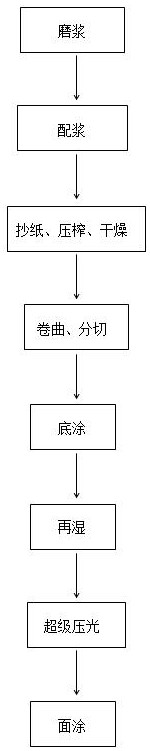

[0032] A preparation method of matt release paper, comprising the following preparation steps:

[0033] (1) Select bleached kraft softwood pulp for refining, and the bleaching kraft softwood pulp has a beating degree of 34°SR as the raw material slurry;

[0034] (2) Add reinforcing agent polyamide-epichlorohydrin PAE and slurry internal sizing agent high-dispersion rosin glue to the raw material slurry, the addition amount of PAE is 1.2%, and the addition amount of high-dispersion rosin glue is 1.5%;

[0035] (3) Carry out papermaking, pressing, drying, coiling, and slitting on the paper machine to obtain the release paper base paper;

[0036] (4) Carry out primer on the surface of the base paper of the release paper, the primer is styrene-acrylate, and the coating amount is 11.7g / m 2 , the coating thickness was 9.6 μm, the drying temperature was 110 °C, and the drying time was 2 min, and the primer coated paper was prepared;

[0037] (5) Rewet the primer paper, adjust the h...

Embodiment 2

[0041] A preparation method of matt release paper, comprising the following preparation steps:

[0042] (1) Select bleached kraft softwood pulp for refining, and the bleaching kraft softwood pulp has a beating degree of 41°SR as the raw material slurry;

[0043] (2) Add the strengthening agent amphoteric polyacrylamide and the internal sizing agent alkyl ketene dimer AKD to the raw material slurry, the addition amount of amphoteric polyacrylamide is 0.8%, and the addition amount of AKD is 1%;

[0044] (3) Carry out papermaking, pressing, drying, coiling, and slitting on the paper machine to obtain the release paper base paper;

[0045] (4) Carry out primer on the surface of the release paper base paper, the primer is carboxylated acrylic acid, and the coating amount is 12.2 g / m 2 , the thickness of the coating is about 10.1 μm, the drying temperature is 105 ℃, and the drying time is 3 minutes, and the primer coated paper is prepared;

[0046] (5) Rewet the primer paper, adju...

Embodiment 3

[0050] A preparation method of matt release paper, comprising the following preparation steps:

[0051] (1) Select bleached kraft softwood pulp for refining, and the bleaching kraft softwood pulp has a beating degree of 43°SR as the raw material slurry;

[0052] (2) Add reinforcing agent carboxymethyl cellulose and pulp internal sizing agent styrene maleic anhydride copolymer ASA to the raw material slurry, the addition amount of carboxymethyl cellulose is 0.6%, and the addition amount of ASA is 1.2%;

[0053] (3) Carry out papermaking, pressing, drying, coiling, and slitting on the paper machine to obtain the release paper base paper;

[0054] (4) Carry out primer on the surface of the release paper base paper, the primer is acrylic acid, and the coating amount is 11.8 g / m 2 , the thickness of the coating is about 10.0 μm, the drying temperature is 110 ° C, and the drying time is 2 min, and the primer coated paper is prepared;

[0055] (5) Rewet the primer paper, adjust the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com