Zinc sulfate solution pH adjusting device for removing chlorine from zinc sulfate solution

A technology of zinc sulfate solution and adjustment device, which is applied to zinc sulfate, feeding device, mixer with rotary stirring device, etc., can solve problems such as low pH adjustment efficiency, and achieve the effect of improving stirring efficiency and improving flow efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

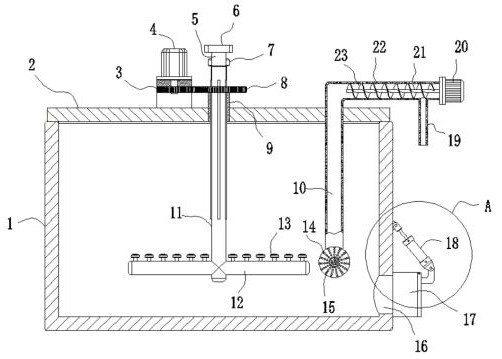

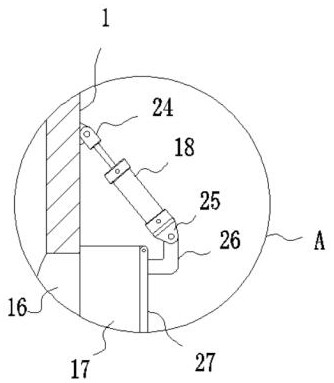

[0022] Such as Figure 1-2 Shown, a kind of zinc sulfate solution pH adjustment device that is used for zinc sulfate solution to remove chlorine comprises a pH adjustment box 1 with an open top, and the top of the pH adjustment box 1 is provided with a cover plate 2 for closing its inside, so A mounting sleeve 9 is vertically embedded on the cover plate 2, and the mounting sleeve 9 is rotatably connected to the cover plate 2, and a stirring shaft 11 is coaxially slidably fitted inside it, and the stirring shaft 11 is connected to the On the installation sleeve 9, its lower end extends into the PH adjustment box 1 and is equipped with a connecting pipe 12. The connecting pipe 12 is provided with a plurality of aeration discs 13 communicating with its interior, and the stirring shaft 11 is closed at the lower end. The tubular structure communicates with the communication pipe 12, the upper end of the stirring shaft 11 is connected with a rotary joint 5, and the rotary joint 5 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com