Preparation method of hyperbranched polybutylene adipate terephthalate material

A butylene phthalate, hyperbranched polymer technology, applied in sustainable manufacturing/processing, bio-packaging, climate sustainability, etc., can solve the problem of poor melt strength, low heat distortion temperature, and high cost of using PBAT problem, to achieve the effect of mild reaction conditions, simple operation steps and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

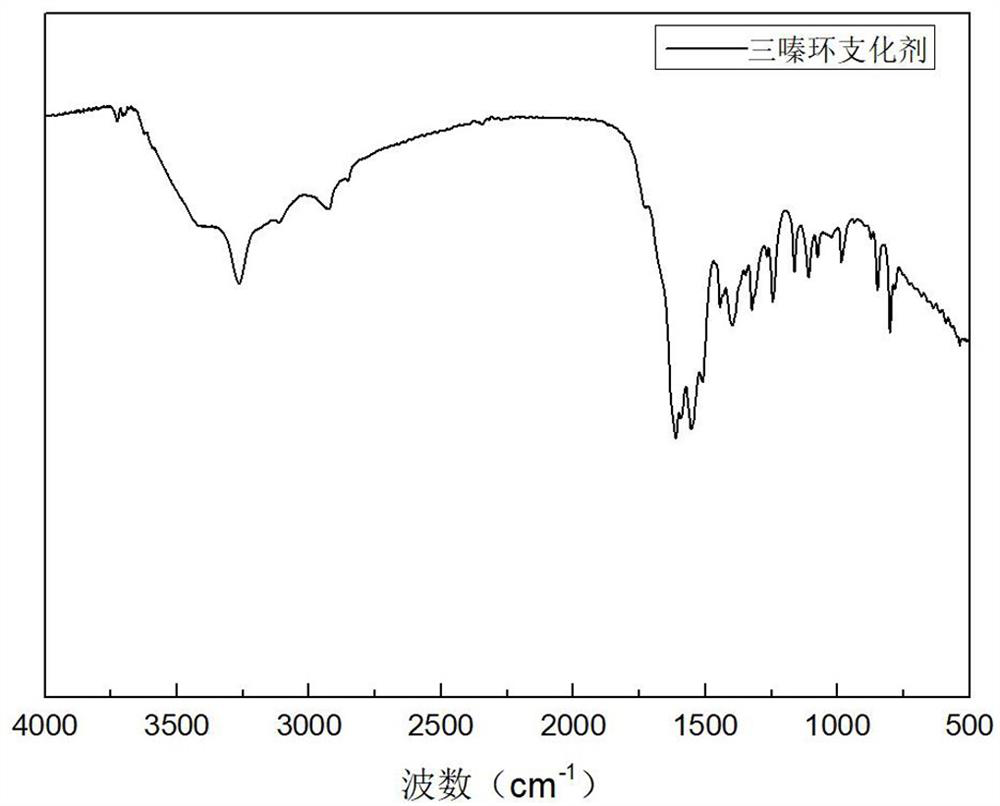

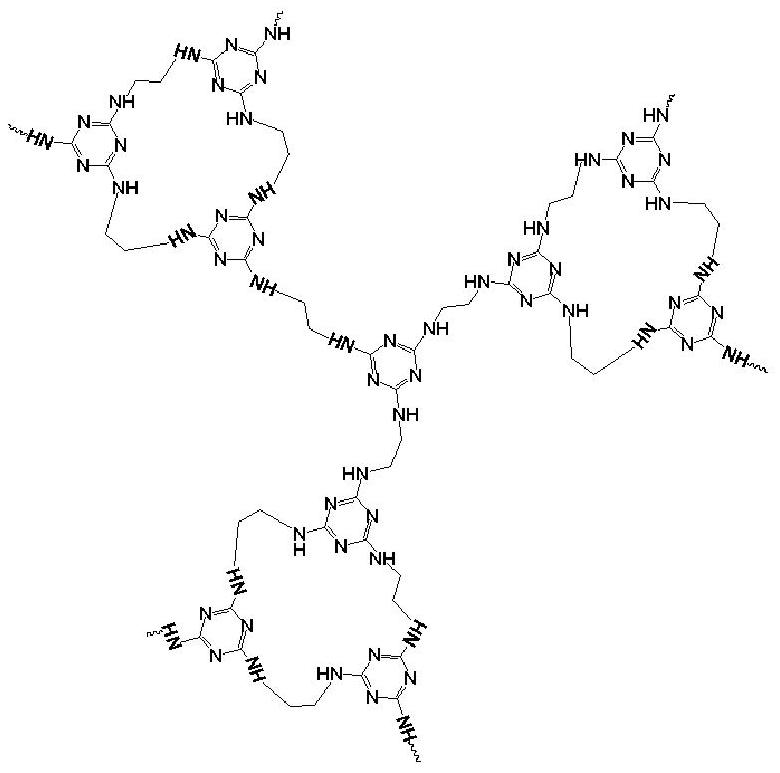

[0031] (1) 24 g of ethylenediamine and 12.7 g of sodium carbonate were dissolved in 125 mL of deionized water at 80° C., and then the aqueous solution was cooled to room temperature.

[0032] (2) Mix 36.9g of cyanuric chloride and 300mL of acetone, add it into a 500ml three-necked flask, and then gradually add the normal temperature solution in (1) dropwise into the reaction system.

[0033] (3) Stir the mixture at -10-0°C and react for 6 hours; heat up to 20-30°C and react for 6 hours; then raise the temperature to 70-80°C and react for 6 hours. During the polymerization process, a large number of bubbles and White particle.

[0034] (4) The reaction mixture was filtered and washed three times with hot deionized water and acetone respectively. The target product was dried in a vacuum oven at 90° C. for 48 hours to obtain a white solid, which is a triazine ring branching agent.

[0035] (5) Put PBAT, triazine ring branching agent and antioxidant into a twin-screw extruder ac...

Embodiment 2

[0037] (1) 24 g of ethylenediamine and 12.7 g of sodium carbonate were dissolved in 125 mL of deionized water at 80° C., and then the aqueous solution was cooled to room temperature.

[0038] (2) Mix 36.9g of cyanuric chloride and 300mL of acetone, add it into a 500ml three-necked flask, and then gradually add the normal temperature solution in (1) dropwise into the reaction system.

[0039] (3) Stir the mixture at -10-0°C and react for 6 hours; heat up to 20-30°C and react for 6 hours; then raise the temperature to 70-80°C and react for 6 hours. During the polymerization process, a large number of bubbles and White particle.

[0040] (4) The reaction mixture was filtered and washed three times with hot deionized water and acetone respectively. The target product was dried in a vacuum oven at 90° C. for 48 hours to obtain a white solid, which is a triazine ring branching agent.

[0041] (5) Put PBAT, triazine ring branching agent and antioxidant into a twin-screw extruder ac...

Embodiment 3

[0043](1) 24 g of ethylenediamine and 12.7 g of sodium carbonate were dissolved in 125 mL of deionized water at 80° C., and then the aqueous solution was cooled to room temperature.

[0044] (2) Mix 36.9g of cyanuric chloride and 300mL of acetone, add it into a 500ml three-necked flask, and then gradually add the normal temperature solution in (1) dropwise into the reaction system.

[0045] (3) Stir the mixture at -10-0°C and react for 6 hours; raise the temperature to 20-30°C and react for 6 hours; then raise the temperature to 70-80°C and react for 6 hours. During the polymerization process, a large number of bubbles and White particle.

[0046] (4) The reaction mixture was filtered and washed three times with hot deionized water and acetone respectively. The target product was dried in a vacuum oven at 90° C. for 48 hours to obtain a white solid, which is a triazine ring branching agent.

[0047] (5) Put PBAT, triazine ring branching agent and antioxidant into a twin-scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com