Polyester bulk molding compound composite material with high pressure resistance and preparation method thereof

A technology of bulk molding compound and composite material, which is applied in the field of high pressure-resistant polyester bulk molding compound composite material and its preparation, polyester bulk molding compound composite material and its preparation, to achieve electrical performance improvement, good durability Effects on compressive and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

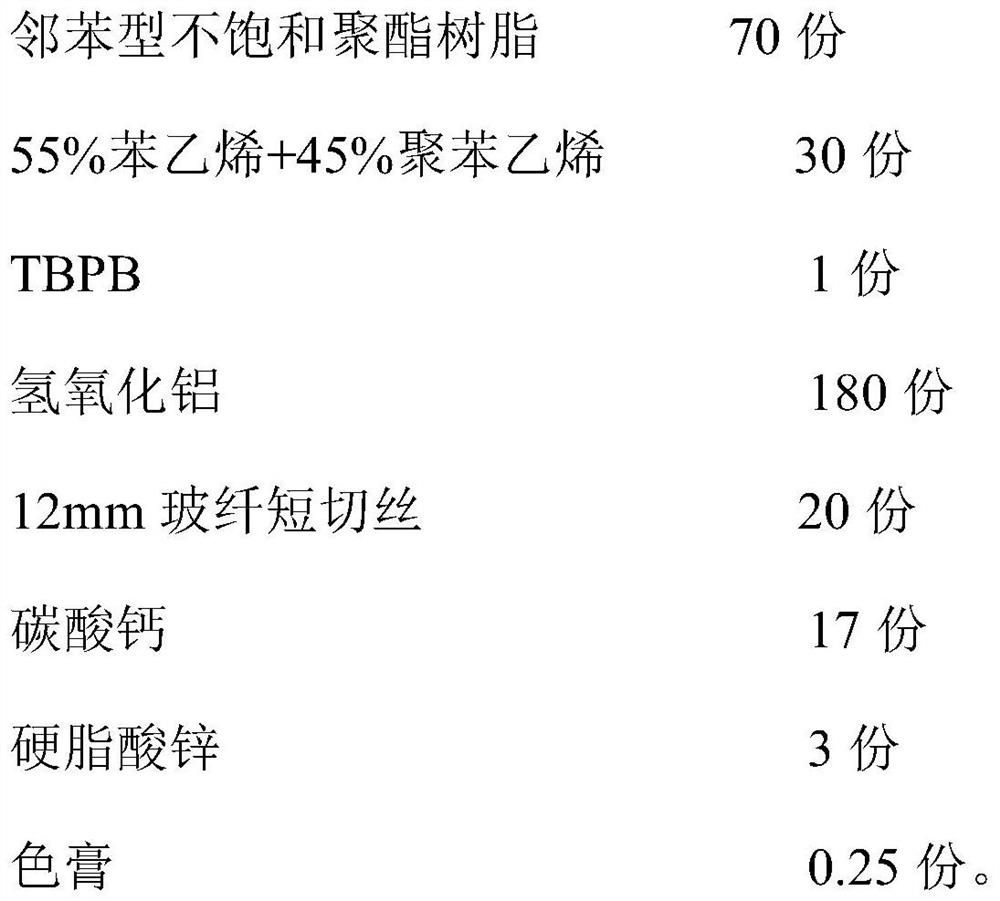

Embodiment 1

[0047] The high-pressure-resistant polyester BMC composite material in this embodiment includes 80 parts of BMC and 20 parts of epoxy resin material in parts by weight.

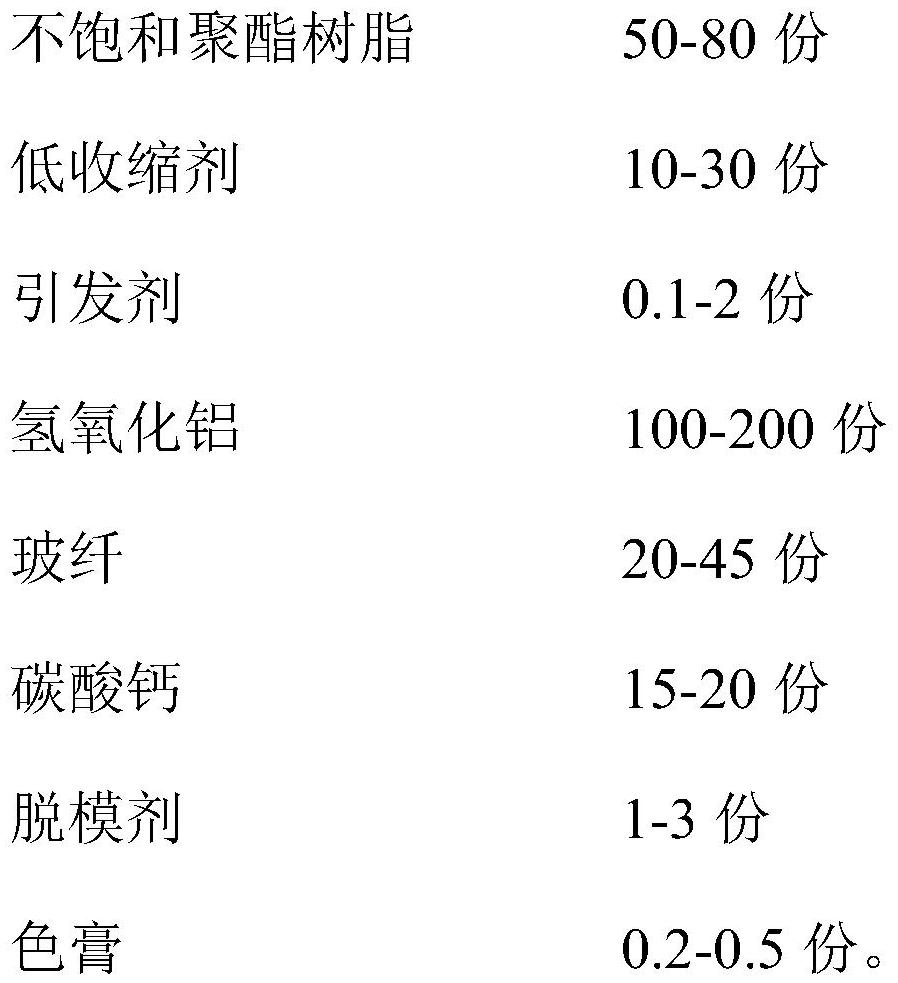

[0048] Wherein, in parts by weight, the bulk molding compound comprises the following components:

[0049]

[0050] Among them, the model of o-phthalic unsaturated polyester resin is P17-902 produced by Jinling Liliansi Resin Co., Ltd., and the model of polystyrene is 666D produced by Yanshan Petrochemical Company.

[0051] The preparation method of bulk molding compound is as follows: according to the above ratio, unsaturated polyester resin, low shrinkage agent, initiator, release agent and color paste are mixed and dispersed, and stirred for 40 minutes to form a paste-like material; Mix and disperse aluminum and calcium carbonate powder fillers, mix and stir with sauce paste material for 8 minutes to prepare a paste material, and finally add glass fiber in the formulated amount to the obtained paste mat...

Embodiment 2

[0056] The difference between this embodiment and embodiment 1 is that the epoxy resin material is compounded by epoxy resin E44 and curing agent low-molecular polyamide 650 with a mass ratio of 8:1, and the others are the same as those of embodiment 1. same.

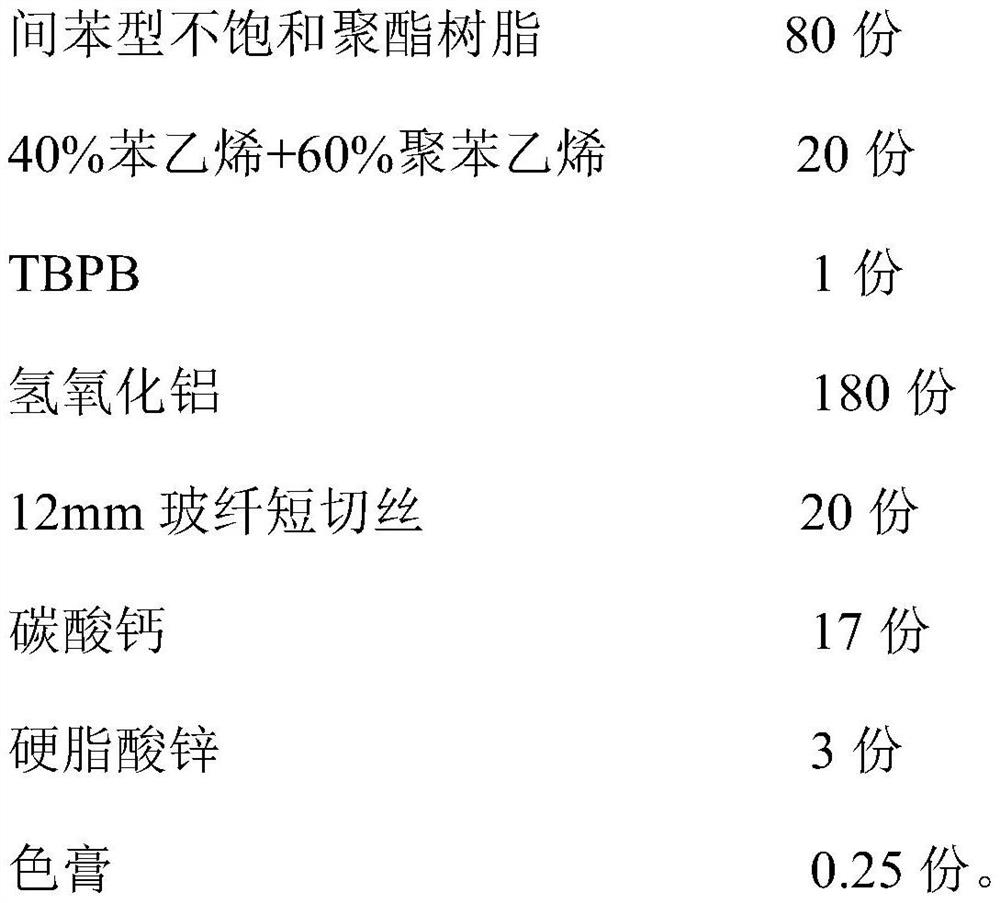

Embodiment 3

[0058] The difference between this embodiment and embodiment 1 is that the epoxy resin material is compounded by epoxy resin E44 and curing agent low-molecular polyamide 650 with a mass ratio of 6:1, and the others are the same as those of embodiment 1. same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com