Low thermal conductivity coefficient organosilicon foam material and preparation method thereof

A technology of silicone foam and low thermal conductivity, applied in the field of silicone foam materials, can solve the problems of inability to block heat, low heat insulation efficiency, and inability to effectively shield radiated electromagnetic waves, etc., and achieve high-efficiency foam insulation, good mechanical properties, The effect of reducing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

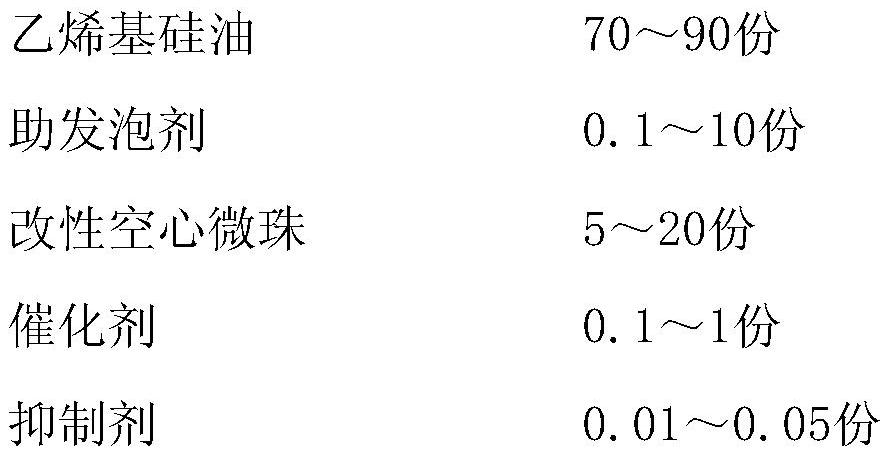

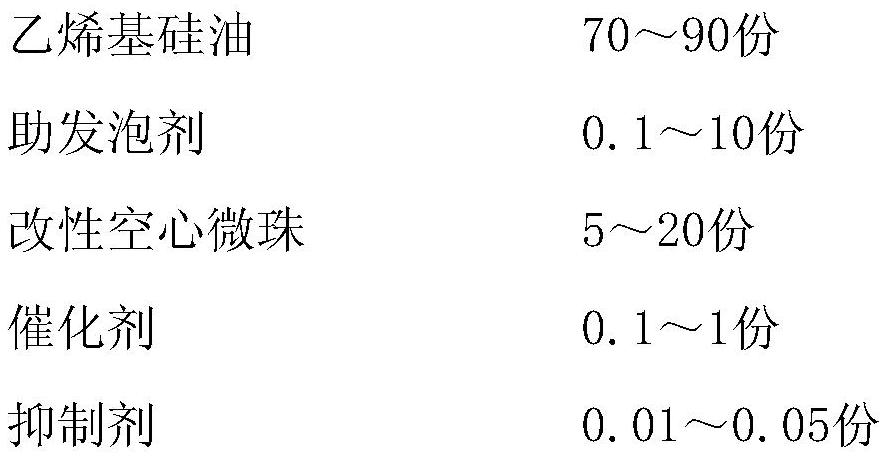

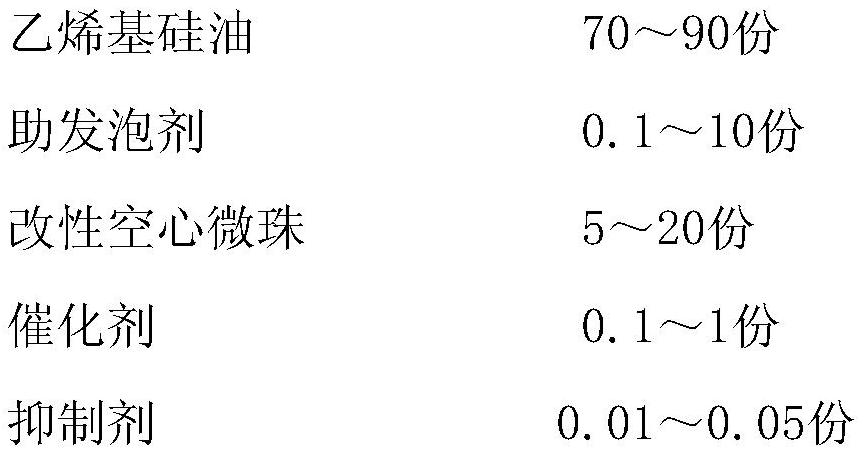

Method used

Image

Examples

preparation example Construction

[0044] Above-mentioned organosilicon foam material, its preparation method comprises the following steps:

[0045] (1) Prepare components A and B, and mix components A and B evenly;

[0046] (2) Mix components A and B evenly, put them into the cavity of the mold, and then heat up and foam through a certain program to form the required low thermal conductivity silicone foam material. Preferably, the temperature programming is specifically: the foaming temperature is 50°C-60°C, the foaming time is 10min-30min, the heat treatment temperature is 150°C-160°C, and the heat treatment time is 2h-3h.

Embodiment 1

[0049] The low thermal conductivity silicone foam material of this embodiment includes A component and B component, wherein, A component is mainly prepared from the following raw materials by weight: viscosity is 50Pa.s, vinyl mass fraction is 0.2% Vinyl silicone oil 60g, viscosity 1000mPa.s, vinyl mass fraction 4% vinyl silicone oil 15g, ethylene glycol 5g, modified hollow glass microspheres 15g, chloroplatinic acid 0.2g, 1-alkynyl cyclohexanol 0.02g; Component B is mainly prepared from the following raw materials in parts by weight: 60g of vinyl silicone oil with a viscosity of 50Pa.s and a vinyl mass fraction of 0.2%, 25g of hydrogen-containing silicone oil with a hydrogen content of 0.75%, modified hollow Glass beads 15g.

[0050] The preparation method of the low thermal conductivity silicone foam material of the present embodiment comprises the following steps:

[0051](1) Add tourmaline with a particle size of 150 μm to 20-30 μm hollow glass microspheres of the same qu...

Embodiment 2

[0057] The low thermal conductivity silicone foam material of this embodiment includes A component and B component, wherein, A component is mainly prepared from the following raw materials by weight: viscosity is 10Pa.s, vinyl mass fraction is 0.5% Vinyl silicone oil 65g, viscosity 1500mPa.s, vinyl mass fraction 3% vinyl silicone oil 15g, ethylene glycol 8g, modified hollow ceramic microspheres 12g, chloroplatinic acid 0.2g, 1-alkynyl cyclohexanol 0.02 g; Component B is mainly prepared from the following raw materials in parts by weight: 65g of vinyl silicone oil with a viscosity of 10Pa.s and a vinyl mass fraction of 0.5%, 25g of hydrogen-containing silicone oil with a hydrogen content of 0.75%, modified hollow ceramics microbeads.

[0058] The preparation method of the low thermal conductivity silicone foam material of the present embodiment comprises the following steps:

[0059] (1) Add tourmaline with a particle size of 150 μm to 20-30 μm hollow ceramic microspheres of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com