Water-based hydrophobic and oleophobic barrier coating, packaging paper and preparation method

A hydrophobic and oleophobic coating technology, which is applied in wrapping paper, wrapping paper, packaging, etc., can solve problems such as difficulty in effective recycling, ecological environmental hazards, and inability to degrade, and achieves benefits for popularization and application, excellent oil resistance, and easy to use Degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

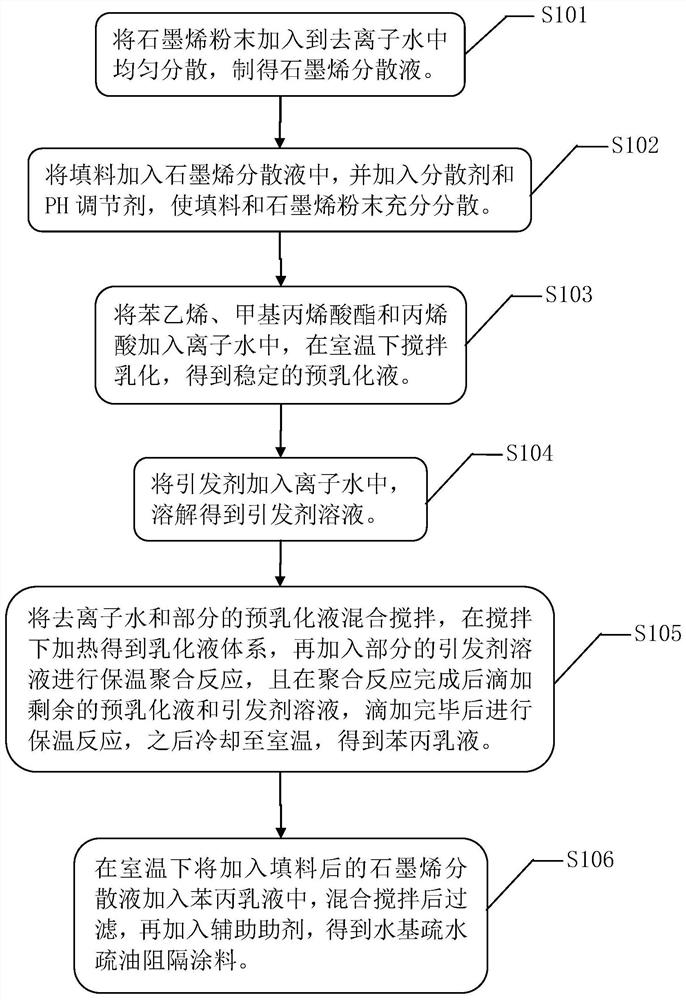

[0032] like figure 1 Shown, the preparation method of a kind of water-based hydrophobic oleophobic barrier coating of the present invention, comprises the following steps:

[0033] Step S101. Adding the graphene powder into deionized water to disperse evenly to obtain a graphene dispersion; specifically, after adding the graphene powder into deionized water, disperse at a speed of 400-600rpm / min for 60-90min , the graphene powder is uniformly dispersed to prepare a graphene dispersion.

[0034] Step S102. Add the filler to the graphene dispersion, and add a dispersant and a pH regulator to fully disperse the filler and the graphene powder; specifically, take a certain amount of filler and slowly add it to the graphene in step S101 Into the dispersion liquid, add a dispersant and a pH regulator, and gradually increase the rotation speed to 1500rpm / min for 0.5-1 hour to ensure that the pigment and graphene are fully dispersed.

[0035] Step S103. Add styrene, methacrylate, acr...

Embodiment 1

[0046] A water-based hydrophobic and oleophobic barrier paper-based coating and a preparation method thereof comprises the following steps:

[0047] (1) 0.4 parts of Graphene are added to deionized water and dispersed for 80min at a rotating speed of 400rpm / min to prepare a uniformly dispersed Graphene solution;

[0048] (2) Weigh 35 parts of kaolin, slowly join in the graphene dispersion in step (1), and add 1 part of dispersant and 0.05 part of pH regulator therein, the rotating speed is gradually increased to 1500rpm, dispersed for 0.5 hours , to ensure that kaolin and graphene are fully dispersed;

[0049] (3) Add styrene 5g, methyl methacrylate 10g, acrylic acid 3g and emulsifier sodium lauryl sulfate, fatty alcohol polyoxyethylene ether to 40g deionized water while stirring, mix and stir 30min evenly, obtain stable pre-emulsion;

[0050] (4) initiator ammonium persulfate 1g and sodium bicarbonate 1g are heated and dissolved in 98g deionized water and stirred and mixed ...

Embodiment 2

[0057] A water-based hydrophobic and oleophobic barrier paper-based coating and a preparation method thereof comprises the following steps:

[0058] (1) 0.6 parts of Graphene are added to deionized water and dispersed for 80min at a rotating speed of 500rpm / min to prepare a uniformly dispersed Graphene solution;

[0059] (2) Weigh 48 parts of talcum powder, slowly join in the graphene dispersion in step (1), and add 2 parts of dispersant and 0.1 part of pH regulator therein, the rotating speed is gradually increased to 1500rpm, disperse 0.5 Hours, to ensure that talcum powder and graphene are fully dispersed;

[0060] (3) Add styrene 6.5g, butyl methacrylate 12g, acrylic acid 4g and emulsifier sodium lauryl sulfate, fatty alcohol polyoxyethylene ether to 50g deionized water while stirring, mix and stir 30min evenly, obtain stable pre-emulsion;

[0061] (4) initiator ammonium persulfate 1.2g and sodium bicarbonate 1g are heated and dissolved in 97.8g deionized water and stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com