Molybdenum telluride-based memristor and preparation method thereof and nonvolatile memory

A technology of memristor and molybdenum telluride, which is applied in the direction of electrical components, can solve the problems of unable to increase the erasing and writing speed, insufficient cycle life, and reduce the energy of molybdenum telluride, etc., and achieve excellent high and low resistance retention, long cycle life, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

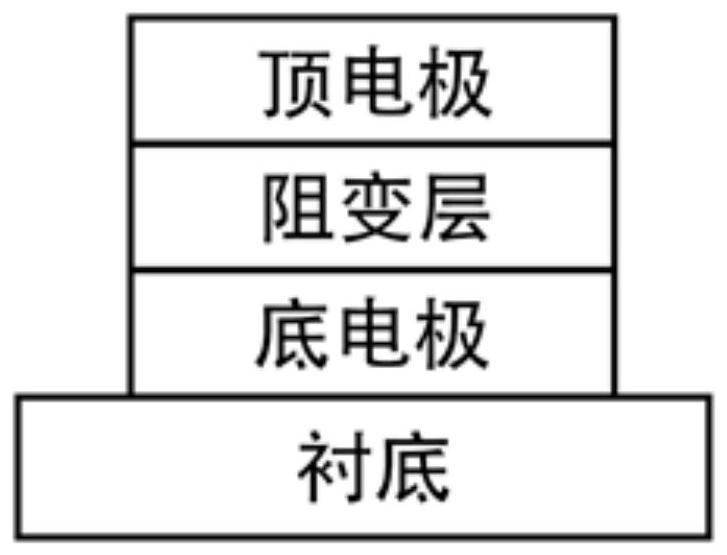

[0033] The structure of the memristor based on the 2H to 1T' phase transition of molybdenum telluride provided in this embodiment is as follows figure 1 As shown, it includes a substrate, a bottom electrode, a top electrode and a resistive switch layer, the bottom electrode is located on the substrate, and the resistive switch layer is located between the bottom electrode and the top electrode.

[0034] In this embodiment, the substrate is a silicon substrate; the bottom electrode is gold and titanium, the thickness of gold is 10nm, and the thickness of titanium is 5nm. Titanium is in contact with the silicon substrate as an adhesion layer, and gold is on the titanium; the top electrode is gold and titanium. The thickness of gold is 50nm, the thickness of titanium is 10nm, the titanium is in contact with the resistive layer below, and the gold is on the titanium; the resistive layer is a two-dimensional molybdenum telluride sheet with a thickness between 5nm and 15nm.

[0035]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com