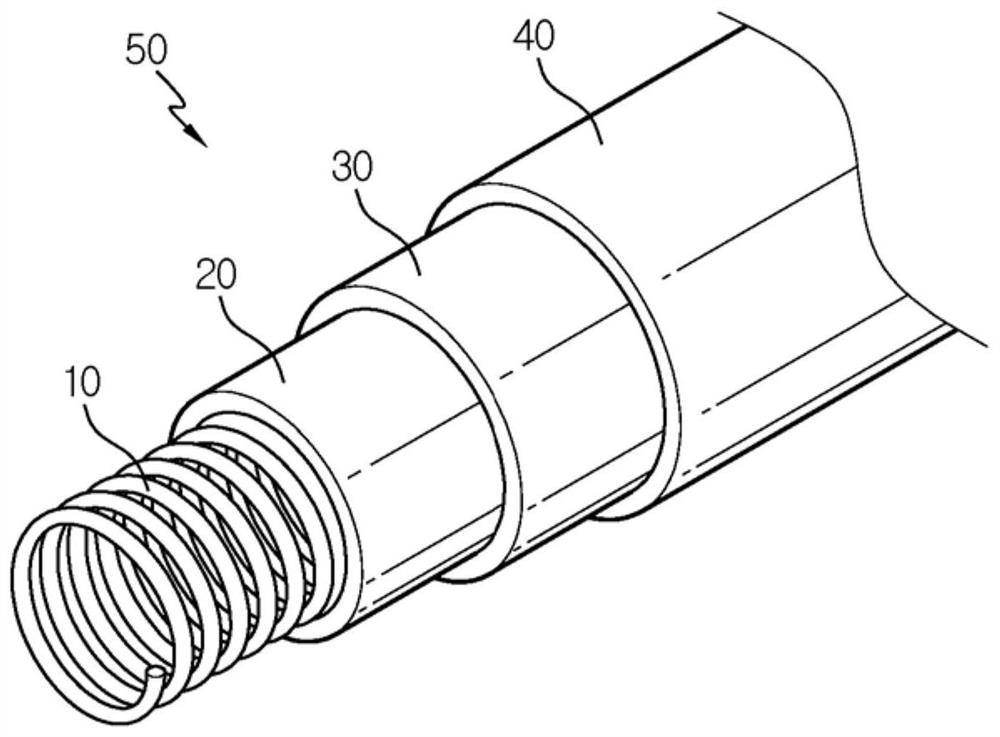

Packaging for flexible secondary battery and flexible secondary battery comprising same

A secondary battery, flexible technology, applied in secondary battery manufacturing, large-size batteries/battery packs, small-size batteries/battery packs, etc., can solve problems such as battery performance degradation, and achieve the effect of reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

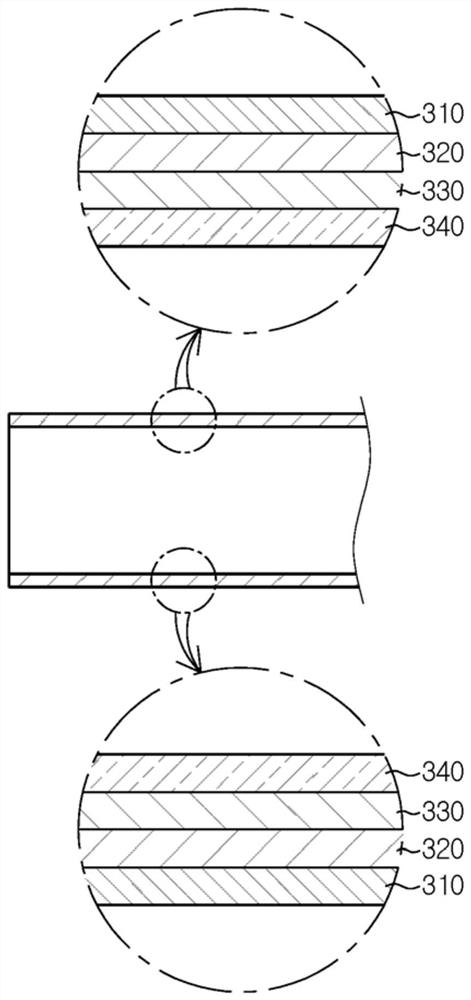

[0116] Formation of Mechanical Support Layers - Reduced Graphene Oxide Layers

[0117] A polyethylene terephthalate film (LAMI-ACE, laminated film) was prepared as a mechanical support layer.

[0118] In order to form a reduced graphene oxide layer on the mechanical support layer, graphene oxide particles (graphene oxide powder (graphene oxide powder), Standard Graphene) were put into deionized water, and energy was applied using an ultrasonic dispersion device to prepare a concentration of 1 mg / mL of graphene oxide dispersion composition. Subsequently, CuCl was added in an amount of 1% by weight based on the weight of graphene oxide 2 (Sigma Aldrich, CuCl 2 ) added to the dispersion composition. The dispersion composition was poured onto the prepared mechanical support layer (ie, polyethylene terephthalate (PET) film), then coated by barcoating and dried to form a graphene oxide layer. The formed graphene oxide layer was immersed in a hydriodic acid solution (TCI, 57% ...

Embodiment 2

[0134] Formation of heat-shrinkable layer-reduced graphene oxide layer

[0135] A modified polyvinylidene fluoride film (YoulChon Chemical) was prepared as the heat-shrinkable layer.

[0136] Graphene oxide particles (graphene oxide powder (graphene oxide powder), StandardGraphen) were put into deionized water, and energy was applied by an ultrasonic dispersion device to prepare a graphene oxide dispersion composition with a concentration of 1 mg / mL. Subsequently, CuCl was added in an amount of 1% by weight based on the weight of graphene oxide 2 (Sigma Aldrich, CuCl 2 ) added to the dispersion composition. The dispersion composition was poured onto the prepared heat-shrinkable layer, and then coated by barcoating and dried to form a graphene oxide layer. The formed graphene oxide layer was immersed in a hydriodic acid solution (TCI, 57% Hydrodic acid) at 90° C. and kept for more than 12 hours. The formed reduced graphene oxide layer was taken out from the hydriodic acid...

Embodiment 3

[0141] The mechanical support layer-reduced graphene oxide layer was obtained by the method described in Example 1.

[0142] A heat-shrinkable tube (Youl Chon Chemical, modified polyvinylidene fluoride tube) was applied as a heat-shrinkable layer to the outside of the mechanical support layer-reduced graphene oxide layer by lamination. In this case, the surface of the reduced graphene oxide layer was modified by UVO oxidation treatment so that the surface energy of the heat-shrinkable layer was equal to that of the reduced graphene oxide. The contact angle of a water droplet was used to determine whether the surface energy of the heat-shrinkable layer and the surface energy of the reduced graphene oxide layer were equal.

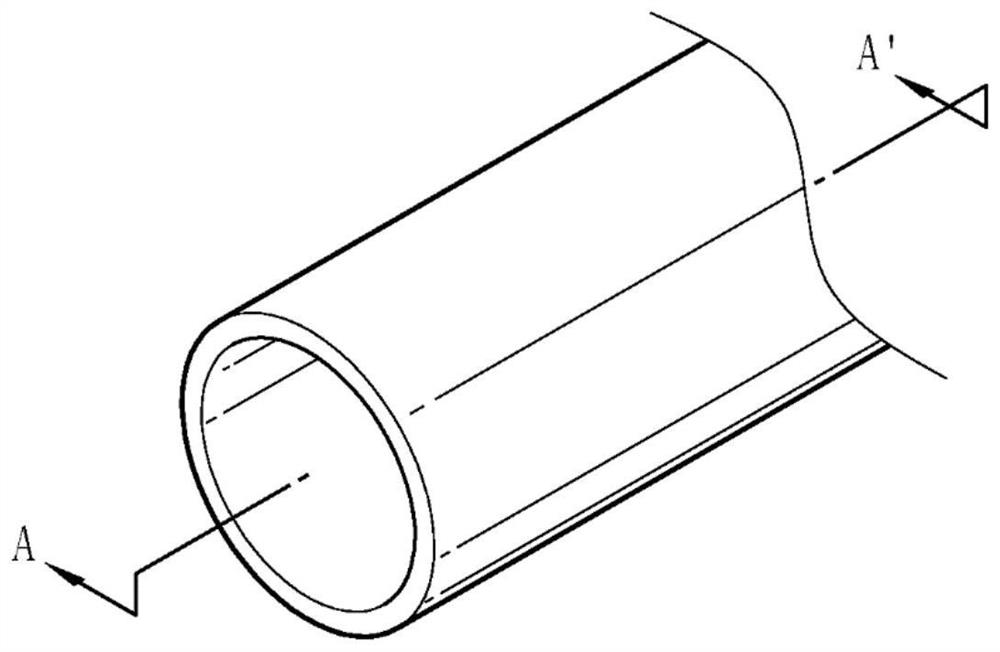

[0143] Subsequently, a package for a flexible secondary battery and a flexible secondary battery were obtained by the same method as in Example 1, wherein the package for a flexible secondary battery was wound around the outer surface of the electrode assemb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com