Bismuth/graphite phase carbon nitride/bismuthyl bromate composite photocatalyst as well as preparation method and application thereof

A technology of composite light and catalyst, used in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as constraints, limitations, high prices, etc. Aids in absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

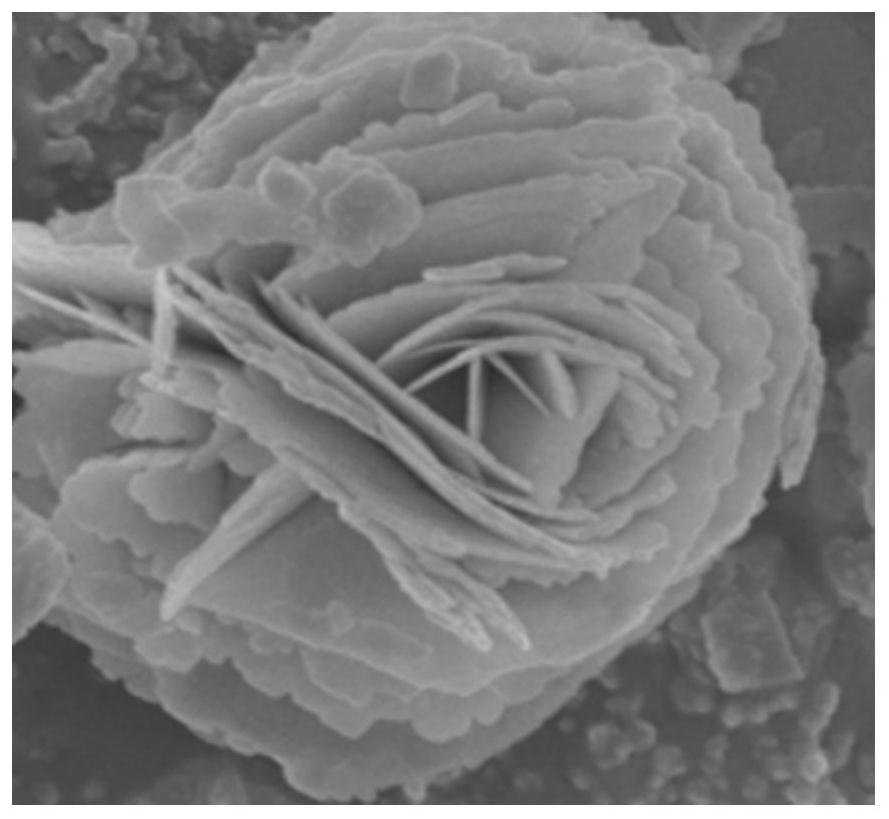

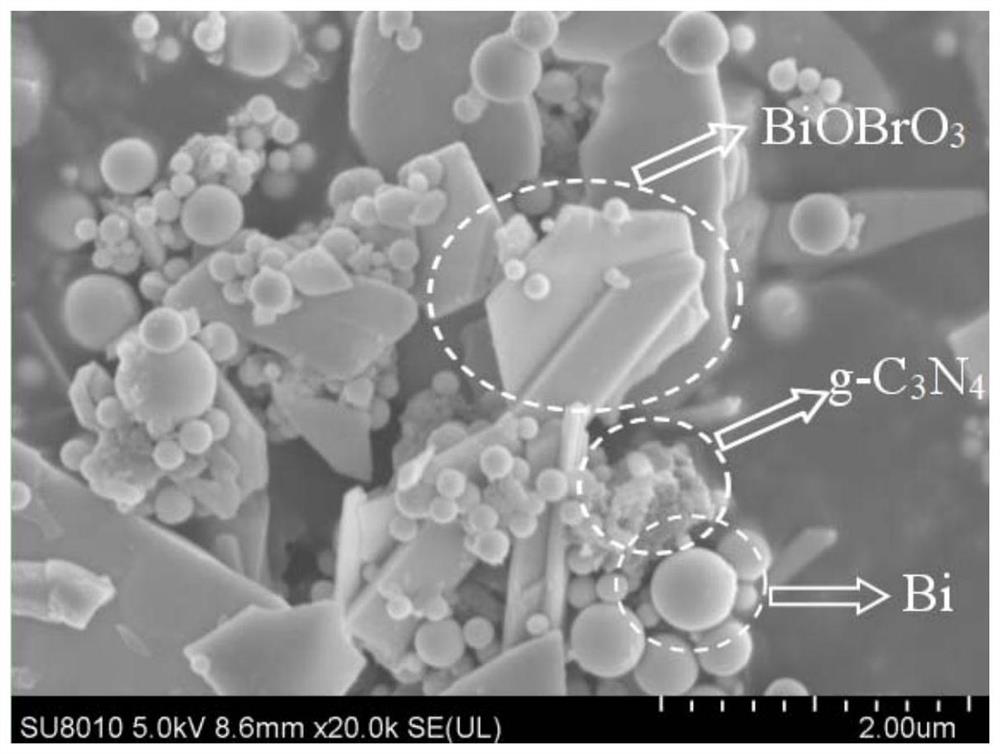

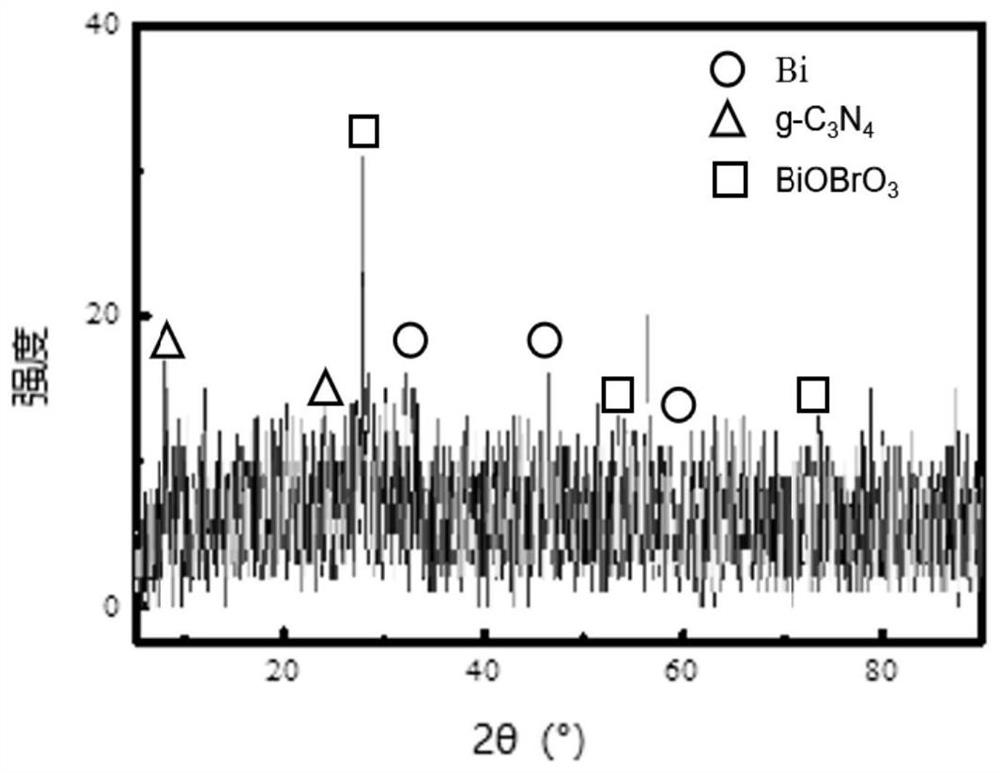

[0035] A Bi / g-C 3 N 4 / BiOBrO 3 The preparation method of composite photocatalyst comprises the steps:

[0036] S1, Bi(NO 3 ) 3 ·5H 2 O and KBrO 3 Dissolve in deionized water, stir evenly, place in a high-pressure reactor, react at 160°C for 12 hours, separate, wash, and dry to obtain BiOBrO 3 powder;

[0037] 0.5g of BiOBrO 3 powder and 0.25g of g-C 3 N 4 Add the powder into 60ml of absolute ethanol, place it in an oven at 160°C for 8 hours, separate the precipitate, wash it, and dry it to obtain g-C 3 N 4 / BiOBrO 3 heterostructure;

[0038] S2, take 0.276g of bismuth nitrate, put it into a 50mL three-hole flask containing 25mL of ethylene glycol, stir for 15min, add 0.1g of NaOH and 0.276g of PVP and stir to dissolve to obtain a suspension, heat from room temperature to 190°C and Keep the reaction for 1 h, and pass N through the whole reaction process. 2 As a protective gas, after the reaction, cool to room temperature, centrifuge at 2000rpm for 30min, and was...

Embodiment 2

[0041] A Bi / g-C 3 N 4 / BiOBrO 3 The preparation method of composite photocatalyst comprises the steps:

[0042] S1, Bi(NO 3 ) 3 ·5H 2 O and KBrO 3 Dissolve in deionized water, stir evenly, place in a high-pressure reactor, react at 150°C for 14h, separate, wash, and dry to obtain BiOBrO 3 powder;

[0043] 0.5g of BiOBrO 3 powder and 0.25g of g-C 3 N 4 Add the powder into 60ml of absolute ethanol, place it in an oven at 150°C for 9 hours, separate the precipitate, wash it, and dry it to obtain g-C 3 N 4 / BiOBrO 3 heterostructure;

[0044] S2, take 0.276g of bismuth nitrate, put it into a 50mL three-hole flask containing 30mL of ethylene glycol, stir for 15min, add 0.1g of NaOH and 0.276g of PVP and stir to dissolve to obtain a suspension, heat from room temperature to 180°C and Keep the reaction for 1.5h, and pass N through the whole reaction process 2 As a protective gas, after the reaction, cool to room temperature, centrifuge and wash to obtain the final produ...

Embodiment 3

[0047] A Bi / g-C 3 N 4 / BiOBrO 3 The preparation method of composite photocatalyst comprises the steps:

[0048] S1, Bi(NO 3 ) 3 ·5H 2 O and KBrO 3 Dissolve in deionized water, stir evenly, place in a high-pressure reactor, react at 170°C for 10h, separate, wash, and dry to obtain BiOBrO 3 powder;

[0049] 0.5g of BiOBrO 3 powder and 0.5g of g-C 3 N 4 Add the powder into 60ml of absolute ethanol, place it in an oven at 170°C for 7 hours, separate the precipitate, wash it, and dry it to obtain g-C 3 N 4 / BiOBrO 3 heterostructure;

[0050] S2, take 0.118g of bismuth nitrate, put it into a 50mL three-hole flask containing 20mL of ethylene glycol, stir for 15min, add 0.1g of NaOH and 0.118g of PVP and stir to dissolve to obtain a suspension, heat from room temperature to 200°C and Keep the reaction for 0.5h, and pass N through the whole reaction process 2 As a protective gas, after the reaction, cool to room temperature, centrifuge and wash to obtain the final produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com