PPS composite material, and preparation method and application thereof

A technology of composite material and PPS resin, which is applied in the field of polymer materials, can solve the problems of insufficient strength during mold release, longer molding cycle, and inability to apply PPS composite materials, etc., to improve the decrease of melt flow rate and increase the crystallization temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

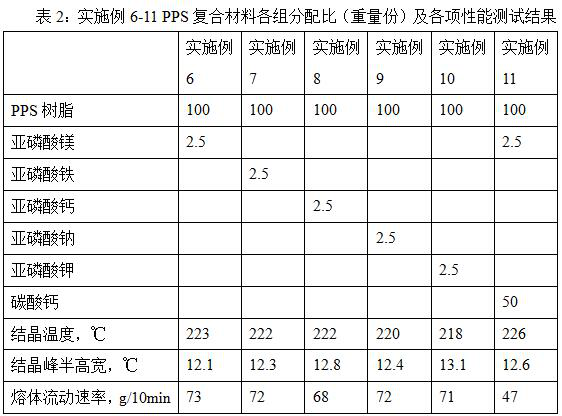

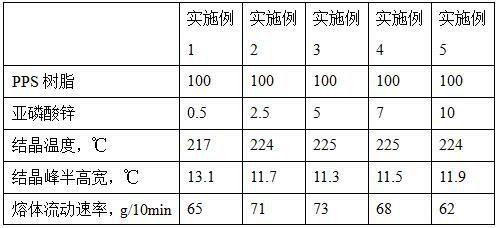

[0020] The present invention is described in more detail by the following examples, but the present invention is not limited by the following examples.

[0021] The raw material that the present invention uses derives from commercially available product:

[0022] PPS resin: PPS 1150C, melt index 60g / 10min (ISO 1133 -2011 standard, 300℃, 1.2kg);

[0023] Magnesium phosphite: commercially available;

[0024] Zinc phosphite: commercially available;

[0025] Iron phosphite: commercially available;

[0026] Calcium phosphite: commercially available;

[0027] Sodium phosphite: commercially available;

[0028] Potassium phosphite: commercially available;

[0029] Calcium carbonate: 800 mesh;

[0030] Aluminum hypophosphite: commercially available.

[0031] The preparation method of the PPS composite material of the example and the comparative example: After mixing each component evenly, add and extrude and granulate through a twin-screw extruder. The twin-screw extrusion proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com