Method for preparing 1,3-butadiene through electro-catalytic acetylene coupling

A technology of butadiene and electrocatalysis, applied in electrodes, electrolysis components, electrolysis process, etc., can solve the problems of poor solubility of acetylene, low current density, electrocatalytic hydrogen evolution side reaction, and no commercial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

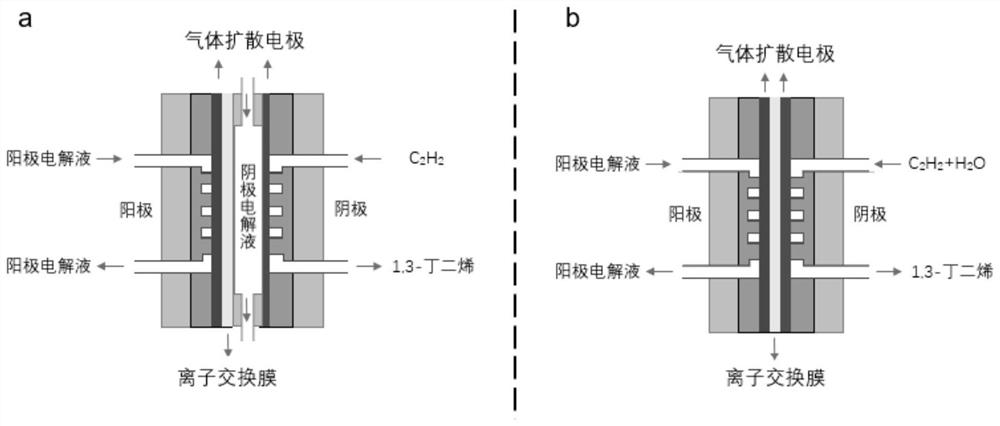

[0053] (1) The gas diffusion electrode made of Fe nanoparticles is used as the cathode of the electrolytic cell; the gas diffusion electrode made of iridium oxide catalyst is used as the anode of the electrolytic cell; both the catholyte and the anolyte are 0.1M KHCO 3 solutions, separated by anion exchange membranes, and as figure 1 The schematic diagram of the apparatus shown assembles the various components.

[0054] (2) Use a gas mass flowmeter to control the flow rate of the acetylene-ethylene mixed reaction gas to 50 sccm.

[0055] (3) A peristaltic pump is used to control the flow rate of catholyte and anolyte to 50 sccm.

[0056] (4) The catalytic activity of Fe nanoparticles was characterized by potentiostatic method.

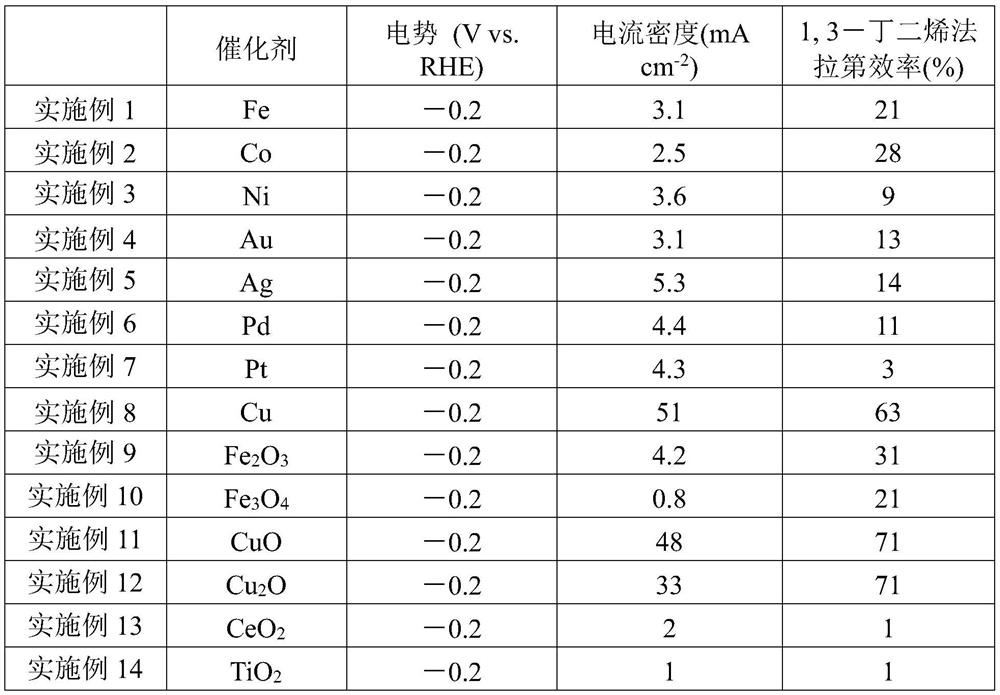

[0057] The catalyst composition and specific evaluation results are shown in Table 1.

Embodiment 2

[0059] (1) The gas diffusion electrode made of Co nanoparticles was used as the cathode of the electrolytic cell; the gas diffusion electrode made of iridium oxide catalyst was used as the anode of the electrolytic cell; both the catholyte and the anolyte were 0.1M KHCO 3 solutions, separated by anion exchange membranes, and as figure 1 The schematic diagram of the apparatus shown assembles the various components.

[0060] (2) Use a gas mass flowmeter to control the flow rate of the acetylene-ethylene mixed reaction gas to 50 sccm.

[0061] (3) A peristaltic pump is used to control the flow rate of catholyte and anolyte to 50 sccm.

[0062] (4) The catalytic activity of Co nanoparticles was characterized by potentiostatic method.

[0063] The catalyst composition and specific evaluation results are shown in Table 1.

Embodiment 3

[0065] (1) The gas diffusion electrode made of Ni nanoparticles is used as the cathode of the electrolytic cell; the gas diffusion electrode made of iridium oxide catalyst is used as the anode of the electrolytic cell; both the catholyte and the anolyte are 0.1M KHCO 3 solutions, separated by anion exchange membranes, and as figure 1 The schematic diagram of the apparatus shown assembles the various components.

[0066] (2) Use a gas mass flowmeter to control the flow rate of the acetylene-ethylene mixed reaction gas to 50 sccm.

[0067] (3) A peristaltic pump is used to control the flow rate of catholyte and anolyte to 50 sccm.

[0068] (4) The catalytic activity of Ni nanoparticles was characterized by potentiostatic method.

[0069] The catalyst composition and specific evaluation results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com