Method for determining thiocyanate in water containing iron-cyanogen complex in gold cyaniding process

A technology of thiocyanate and determination method, which is applied in the direction of material analysis, measurement device, and preparation of test samples by observing the influence on chemical indicators, and can solve the interference of ferricyanide complex and thiocyanate Unstable color development and other problems, to achieve the effect of increasing the absorbance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Include the following steps:

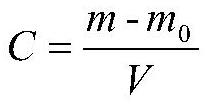

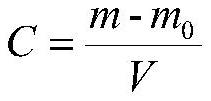

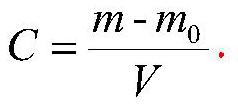

[0034] Step 1, measure the volume V 1 Put 100mL of thiocyanate water sample in a 250mL beaker, add hydrochloric acid to adjust the pH to 3, add 0.1g of masking agent 1, shake well, add sodium hydroxide to adjust the pH of the solution to 7, add 0.1g of masking agent 2. Heat and boil for 20 minutes, remove and cool, and dilute to a 100mL volumetric flask;

[0035] Step 2, take a 100mL beaker, filter the above solution with quantitative filter paper, and discard the initial filtrate;

[0036] Step 3, the drawing of the standard curve

[0037] Add thiocyanate standard solution 0mL, 0.50mL, 1.00mL, 2.00mL, 3.00mL, 5.00mL to six 50mL brown stoppered colorimetric tubes respectively, then add to six 50mL stoppered colorimetric tubes respectively Add 1mL of ethanol to dilute to the marked line with 5mL of ferric chloride color reagent, shake well, place it in a dark place for 5 minutes and measure it. At this time, the contents of thiocyanate i...

Embodiment 2

[0049] Include the following steps:

[0050] Step 1, measure the volume V 1 Put 100mL of thiocyanate water sample in a 250mL beaker, add hydrochloric acid to adjust the pH to 5, add 0.1g of ferrous sulfate, shake well, add sodium hydroxide to adjust the pH of the solution to 8, add 0.1g of zinc sulfate , heating and boiling time is 20min, remove and cool, and set the volume to 100mL volumetric flask;

[0051] Step 2, take a 100mL beaker, filter the above solution with quantitative filter paper, and discard the initial filtrate;

[0052] Step 3, the drawing of the standard curve

[0053]Add thiocyanate standard solution 0mL, 0.50mL, 1.00mL, 2.00mL, 3.00mL, 5.00mL to six 50mL brown stoppered colorimetric tubes respectively, then add to six 50mL stoppered colorimetric tubes respectively Add 1mL of ethanol to dilute to the marked line with 5mL of ferric chloride color reagent, shake well, place it in a dark place for 5 minutes and measure it. At this time, the contents of thioc...

Embodiment 3

[0065] Including the following steps:

[0066] Step 1, measure the volume V 1 Put 100mL of thiocyanate water sample in a 250mL beaker, add hydrochloric acid to adjust the pH to 4, add 0.1g of masking agent 1, shake well, add sodium hydroxide to adjust the pH of the solution to 7.5, add 0.1g of masking agent 2, Heat and boil for 20 minutes, remove and cool, and dilute to 100mL volumetric flask;

[0067] Step 2, take a 100mL beaker, filter the above solution with quantitative filter paper, and discard the initial filtrate;

[0068] Step 3, the drawing of the standard curve

[0069] Add thiocyanate standard solution 0mL, 0.50mL, 1.00mL, 2.00mL, 3.00mL, 5.00mL to six 50mL brown stoppered colorimetric tubes respectively, then add to six 50mL stoppered colorimetric tubes respectively Add 1mL of ethanol to dilute to the marked line with 5mL of ferric chloride color reagent, shake well, place it in a dark place for 5 minutes and measure it. At this time, the contents of thiocyanate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com